| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | TPO Waterproof Membrane |

|---|---|

| Brand Name: | HAOBANG |

| Model Number: | 1.2mm TPO waterproof membrane |

| Certification: | ISO |

| Place of Origin: | Shandong,China |

| MOQ: | 1,000 square meters |

| Price: | Price negotiable |

| Payment Terms: | T/T,L/C |

| Supply Ability: | 680000 square meters per year |

| Delivery Time: | 6-7 work days |

| Packaging Details: | Packed in Roll and on Pallet |

| Application: | Roof |

| Design Style: | Traditional |

| Width: | 1m/2m |

| Length: | 20m/roll |

| Roofing Application: | Planted Roofs |

| Wind Uplift Resistance: | 4.3 Kpa |

| Uv Resistance: | ≥1500h |

| Port: | qingdao |

| Low Temperature Flexibility: | -40℃ |

| Material: | Thermoplastic Polyolefin |

| Sample Request: | free |

| Transport Packages: | Tray Packaging |

| Company Info. |

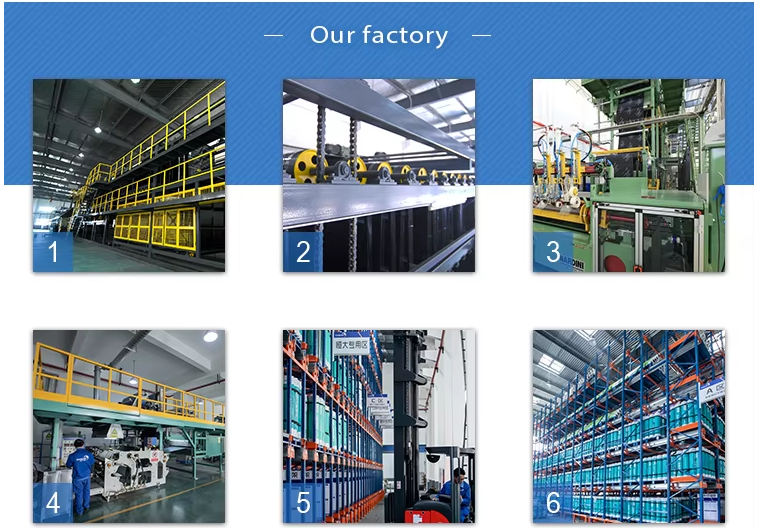

| Weifang Haobang Waterproof Materials Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Product Description

| Product Name | 1.2mm TPO Roofing Membrane (Smooth Version) |

| Material | TPO |

| Color | White |

Composed of thermoplastic polyolefin (TPO), integrating the fusibility of propylene-alpha-olefin copolymer resins via cutting-edge polymerization techniques and the robustness of polypropylene resins, Haobang TPO-H is a uniform multi-layered composite thermoplastic polyolefin polymer waterproof sheet crafted by sophisticated processing methods, applied for the meticulous treatment of open rooftops.

Technical Data Sheet

| GB27789-2011 TPO Waterproofing Membrane(Type H) | |||

| Tensile Properties | Value | ||

| Tensile strength | ≥ | MPa | 12 |

| Elongation at rapture | % | 500 | |

| Dimensional change rate on heating | % | 2 | |

| Low temperature bending | - | -40℃No Cracks | |

| Watertightness | - | 0.3 MPa,2h Watertight | |

| Impact resistance | - | - | 0.5 kg ·m, No water leakage |

| Peel strength at joints | N/mm | 4.0 or damaged | |

| Right angle tear strength | N/mm | 60 | |

| Water Absorption Rate(70℃168h) | % | 4 | |

| Heat aging (115℃) | |||

| Time | - | h | 672 |

| Appearance | - | - | No blistering,cracks,delamination,sticking or voids |

| Tensile strength retention | ≥ | % | 90 |

| Elongation retention at rapture | ≥ | % | 90 |

| Low temperature bendability | - | - | -40, No Cracks |

| Chemical resistance | |||

| Appearance | - | - | No blistering,cracksdelaminationsticking or voids |

| Tensile strength retention | ≥ | % | 90 |

| Elongation retention at rapture | ≥ | % | 90 |

| Low temperature bendability | - | - | -40℃,No Cracks |

| Artificial climate accelerates aging | |||

| Time | - | h | 2500 |

| Appearance | - | - | No blisteringcracks,delamination,sticking or voids |

| Tensile strength retention | % | 90 | |

| Elongation retention at break | ≥ | % | 90 |

| Low temperature bendability | -40℃, No Cracks | ||

| Wind uplift resistance | 4.3Kpa | 90 | |

Application

Advantages

Outstanding fusibility;

Superb cold-weather malleability;

Superlative dimensional consistency;

Exceptional stretching ability;

Robust shock tolerance;

High solar reflectance;

Eco-conscious, reusable;

Sustained UV resilience

Specification

FAQ

|