| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Sanitary Napkin Making Machine |

|---|---|

| Brand Name: | Womeng |

| Model Number: | WM-FSS01 |

| Certification: | CE |

| Place of Origin: | Fujian, China |

| MOQ: | 1 piece |

| Price: | $300,000-$400,000 |

| Payment Terms: | L/C,D/A,D/P,T/T |

| Supply Ability: | 30sets/year |

| Delivery Time: | 60-100days |

| Packaging Details: | Seaworthy Wooden Box |

| Control System: | PLC |

| Production Speed: | 1500 pcs/min |

| Packaging System: | Auto Stacker (Customized Design) |

| Raw Material: | Fluff Pulp, SAP, Non-woven Fabric, PE Film, Release Paper |

| Packing Details: | Plywood pallets wrapped by PE film |

| Cutting System: | Servo motor control |

| Company Info. |

| Quanzhou Womeng Intelligent Equipment Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Product Info

Product size | 25m*2.5m*3m(for reference only) |

Product structure | Product structure: upper & lower tissue, cotton core (mix with SAP), cover sheet hydrophilic non-woven , ADL (Acquisitiondistribution layer) non-woven,leak guard hydrophobic non-woven back sheet,Waist band non-woven,color pattern sticker,elastic waist band, discarding sticker. |

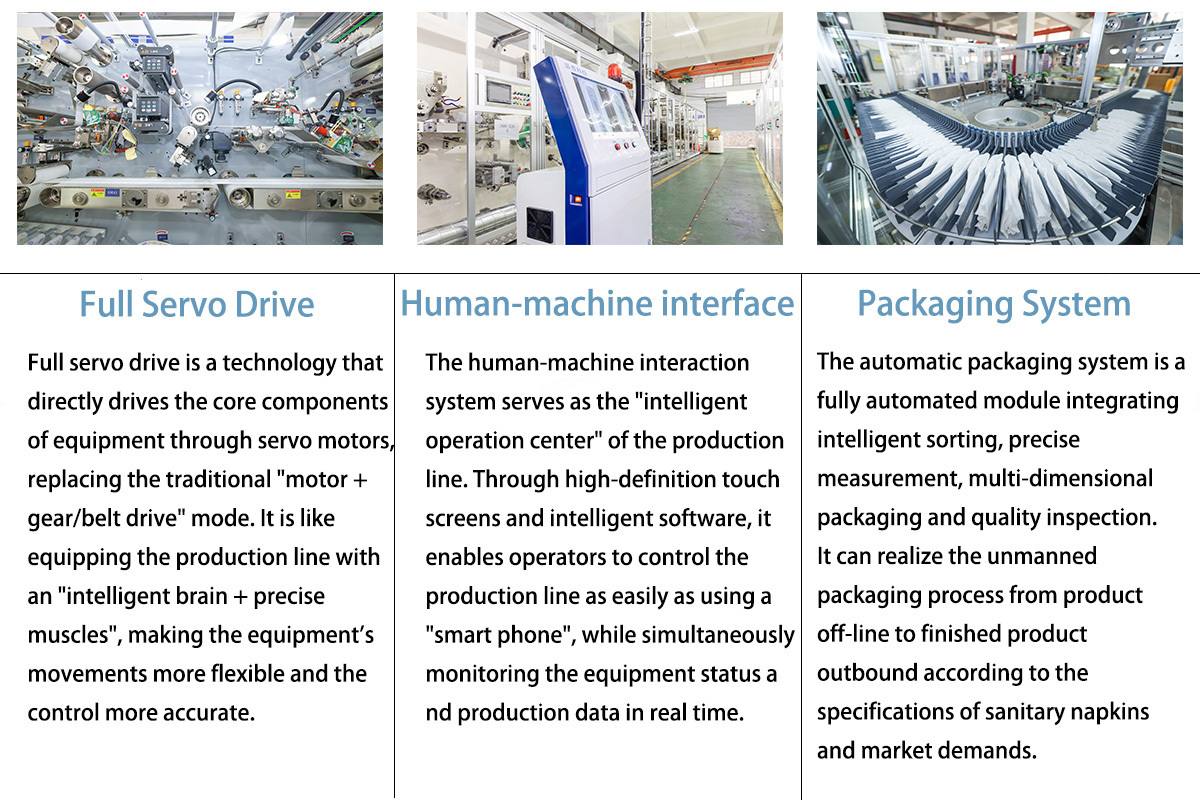

Control system | PLC control system,HMI Operating on the LED touch screen,Configure

HDTV monitor |

Drive system | Servo Drive(Easy to change size), timing belt and flat be |

Tension system | Top tissue paper,bottom tissue paper,hydrophobic nonwoven(leg

cuff),top nonwoven,ADL,back sheet,elastic nonwoven are adopt

A&Blt are import products, and all the key parts, are import

bearings. shaft active unwinding by inverter motor. |

Safety system | It has safety device on the operating side, matched with urgent

stop switch.High audio fan uses sound insulation or silencer. |

| Packaging system | according to customer requirements with palletizer machine (double push double exit ) adjustable |

Materials corrective system | Materials corrective system: Adopt international famous brand deviation correction system |

Power | 380V, 50HZ three phase five wire |

Machine Capacity | 400KW (Excluding glue machine and air compressor) |

Bleed pressure | 0.6-0.8Mpa (Air compressor needs to be prepared by customers) |

| Machine weight | 50 Tons approximately |

Quanzhou Womeng Intelligent Equipment Co., Ltd. is located in

Quanzhou, the cultural capital of East Asia and the starting point

of the Maritime Silk Road. Founded in 2016, it is an enterprise

focusing on the R&D, manufacturing and sales of paper

equipment. The products cover sanitary napkin equipment, diaper

equipment, pant equipment, mattress equipment, pad equipment, etc.

The company has excellent products, professional sales and

technical teams, complete supporting facilities, and according to

different market product specifications, each equipment is

customized according to the actual needs of users, and has rich

experience and technical capacity in the design and production of

equipment.

Adhering to the business philosophy of honesty, cooperation and

win-win, the company wholeheartedly provides high-quality products

and services for new and old customers to meet the needs of

customers to the greatest extent. Serving customers and achieving

customers, "pioneering and innovating, pursuing excellence" is the

constant pursuit of Womeng Equipment. We sincerely look forward to

cooperating with new and old customers to create the future!

Whatsapp: +008615805080212

https://www.diapersmachines.com

Climate adaptability and durable design

High temperature and high humidity resistance

The electronic control system is equipped with a forced air cooling device (suitable for an ambient temperature of 40℃), and the key circuit boards are coated with three-proof varnish (moisture-proof, salt spray-proof, and mold-proof), which can still operate stably in the tropical rainforest climate of Brazil and the high-humidity coastal environment of Venezuela (with a failure rate 50% lower than that of competing products).

The mechanical transmission components are made of stainless steel (304L) to prevent rust caused by the dampness of the rainy season in South America. The maintenance cycle is extended to 6 months (3 months for traditional equipment), reducing the maintenance costs of remote factories in regions such as the Amazon.

Dust-proof and anti-interference optimization

Dust covers are installed on the exposed parts of the production line (to adapt to the dusty environment in the Pampas of Argentina and the deserts of Mexico), and the servo motors adopt sealed bearings to reduce equipment failures caused by sand and dust entering, ensuring continuous production in windy and sandy countries such as Peru and Chile.

Hygiene standards and intelligent upgrades

Basic hygiene design

The surface of the equipment is made of food-grade stainless steel

(304), which is easy to clean and disinfect, meeting the hygiene

requirements in the high-temperature and high-humidity environment

of South America. The glue circuit system is fully enclosed to

prevent the leakage and contamination of hot melt glue, which

complies with the production standards for feminine hygiene

products stipulated in Brazil's Consumer Product Safety Law.

Intelligent primary adaptation

Equipped with a 10-inch touch screen (supporting Spanish/Portuguese), the operation interface is graphically guided, and local workers can master the basic operation within one week. Integrate the "Production data statistics function", automatically record data such as production capacity and yield rate, and help enterprises in countries like Chile and Uruguay achieve basic information management.

|