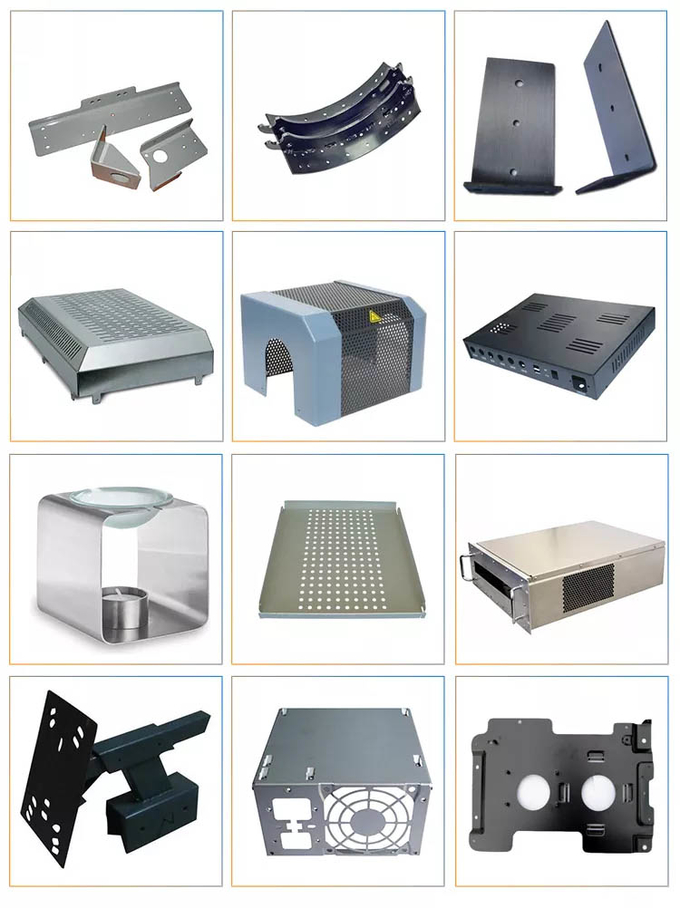

Customized Metal Cabinet Assembly for Your Automotive Industry

Needs Precision-Crafted Trusted OEM Vendor

Description of Customized Metal Cabinet Assembly for Your

Automotive Industry Needs Precision-Crafted Trusted OEM Vendor

Our Customized Metal Cabinet Assembly solutions are meticulously

engineered to cater specifically to the unique and demanding

requirements of the automotive industry. As a trusted Original

Equipment Manufacturer (OEM) vendor, we specialize in delivering

precision - crafted metal cabinets that seamlessly integrate into

automotive production environments. Our team of skilled engineers

and technicians collaborates closely with automotive clients to

understand their exact specifications, from dimensions and load -

bearing capacities to specialized features such as cable management

systems, shock - resistance, and compatibility with automotive

assembly line equipment. We utilize high - quality metals and

advanced manufacturing techniques to ensure the durability,

reliability, and longevity of our cabinets, even in the harsh and

fast - paced automotive manufacturing settings.

Specification of Customized Metal Cabinet Assembly for Your

Automotive Industry Needs Precision-Crafted Trusted OEM Vendor

| CNC Capacity |

| CNC Machining Center | 3 / 4 / 5 axis CNC Machining Centers | 40+ CNC Machines |

| CNC Turning | φ0.5 - φ300 * 750 mm | DIN-2768-Fine +/-0.005 mm |

| CNC Machining | 1270×508×635 mm(max) | DIN-2768-Fine +/-0.005 mm |

| CNC Stamping | 1000 * 1000 mm(max) | DIN-2768-Fine +/-0.005 mm |

| Drawing Format | IGS,STP,X_T ,DXF,DWG , Pro/E, PDF |

| Inspection Equipments | Measurement Instrument, Projector, CMM, Altimeter, Micrometer,

Thread Gages, Calipers, Pin Gauge etc. |

| Material Available |

| Stainless Steel | SS201,SS301, SS303, SS304, SS316, SS416, 17-4PH, etc. |

| Steel | Mild steel, Carbon Steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

| Copper | C11000,C12000,C12000 C36000 etc. |

| Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

| Iron | A36, 45#, 1213, 12L14, 1215 etc. |

| Plastic | ABS, PC, PE, POM, Delrin, Nylon, Teflon, PP,PEI, Peek etc. |

| Surface Finishing |

| Aluminum Parts | Stainless Steel Parts | Steel Parts | Copper /Brass | Plastic Parts |

| Clear Anodized | Polishing | Zinc plating | Polishing | Painting |

| Color Anodized | Passivating | Oxide black | Passivation | Chrome plating |

| Sandblast Anodized | Sandblasting | Nickel plating | Galvanized | polishing |

| Chemical Film | Laser engraving | Chrome plating | Nickel Plating | Sandblast |

| Brushing | | Carburized | Chrome plating | Laser engraving |

| Polishing | | Heat treatment | | |

| Chroming | | Powder Coated | | |

Application Of Customized Metal Cabinet Assembly for Your

Automotive Industry Needs Precision-Crafted Trusted OEM Vendor

1. Auto Components Hardware Parts Auto Parts

2. Communication Equipment

3. Industrial Equipment

4. Medical EquipmentsMechanical Parts

5. Ship Accessories

6. Electrical Equipment

7. Mechanical Equipment

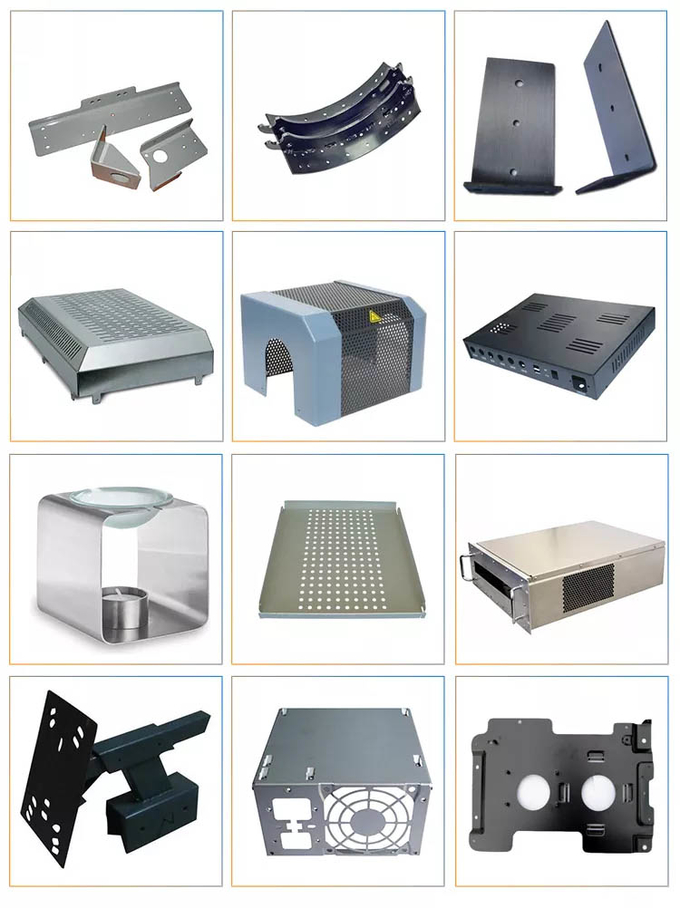

Feature Of Customized Metal Cabinet Assembly for Your Automotive

Industry Needs Precision-Crafted Trusted OEM Vendor

1. Good corrosion resistance

2. High strength and hardness

3. High thermal conductivity

4. Good finishing characteristics

Advantages

1. Tailored Design for Optimal Integration

Customization Flexibility: We recognize that every automotive

facility has its own layout, workflow, and storage needs. Our

customized metal cabinets can be designed to fit precisely into

available spaces, whether it's a compact area near a production

line or a large - scale warehouse. For example, we can adjust the

height, width, and depth of the cabinets to match the specific

dimensions of the automotive parts they will house.

Functional Adaptability: Beyond size, we can incorporate various

functional elements into the cabinets. This includes adjustable

shelves, drawers with specialized dividers for different - sized

automotive components, and locking mechanisms to ensure the

security of valuable or sensitive items. This level of

customization allows for efficient organization and easy access to

parts, reducing downtime in the production process.

2. High - Quality and Durability

Premium Materials: We source only the highest - quality metals,

such as stainless steel or heavy - duty carbon steel, which offer

excellent resistance to corrosion, wear, and tear. In the

automotive industry, where cabinets may be exposed to oils,

chemicals, and physical impacts, these materials ensure the long -

term performance of the cabinets.

Robust Construction: Our manufacturing process involves advanced

welding and finishing techniques, resulting in cabinets that can

withstand heavy loads and rough handling. The joints are strong and

secure, preventing any structural weaknesses that could lead to

failure over time. This durability translates into lower

maintenance costs and a longer service life for the cabinets.

3. Precision Engineering for Reliability

Tight Tolerances: We maintain strict quality control throughout the

manufacturing process to ensure that all dimensions and

specifications are met with high precision. This is crucial in the

automotive industry, where even small deviations can cause problems

in the assembly line. Our cabinets are designed to fit perfectly

with other equipment and components, reducing the risk of

misalignment or interference.

Consistent Performance: With precision engineering, our metal

cabinets offer consistent performance in terms of functionality.

For instance, the drawers slide smoothly, the doors close tightly,

and the locking mechanisms work reliably every time. This

reliability is essential for maintaining the efficiency and

productivity of automotive operations.

4. Expert Support and After - Sales Service

Pre - Sales Consultation: Our team of experts provides

comprehensive pre - sales consultation services. We work closely

with automotive clients to understand their needs, offer design

suggestions, and provide cost - effective solutions. This ensures

that clients get the most suitable metal cabinets for their

specific applications.

Post - Sales Support: After the cabinets are delivered and

installed, we offer ongoing after - sales support. This includes

troubleshooting, repairs, and maintenance services. If any issues

arise, our technicians are available to respond quickly and resolve

them, minimizing any disruption to the automotive production

process.

FAQ

Q: How can I customize my products ?

A: Please describe your project. Include the following information

so that we can provide an accurate quote: Part Name, 3D CAD

Drawing, Quantity, Material, Color, Finishing.

Q: How can I know my products going on ?

A: We will offer a detailed production schedule and send weekly

reports with digital pictures and videos which show the production

process.

Q: Can You sign a confidentiality greement ?

A: We can sign a confidentiality agreement according to your needs.

Q: What is your terms of payment ?

A: 30% in advance ,70% balance before shipment. Other terms

negotiable.

Q: Are you a trading company or factory?

A: We are direct factory with 20 experienced engineers and more

than 80 employees as well approximate 3,000 square meters workshop

area.

Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory,then we can copy or

provide you better solutions. Please send us pictures or drafts

with dimensions(Length, Height, Width), CAD or 3D file will be made

for you if placed order.