Tin Free Steel for Food Packaging with Non-toxic Barrier Properties

and Recyclability

Tin free steel adopts low-carbon steel substrate and

chromium-chromium oxide composite film design to form a dense

protective barrier:

1,Food-grade safety protection: There is no metal tin coating on

the surface to eliminate the risk of tin ion migration. It is

tested to be completely free of harmful heavy metals such as lead

and cadmium. It can also ensure safety even when in direct contact

with food. It is especially suitable for sensitive categories such

as infant food and health products.

2,Efficient barrier preservation: The composite film layer can

isolate oxygen, moisture and light to prevent food from oxidation

and deterioration. It has excellent acid and salt resistance.

Whether it is acidic foods such as carbonated beverages and

ketchup, or salt-containing scenes such as soy sauce and canned

food, it can keep the contents fresh for a long time.

3,High temperature resistant and stable characteristics: It can

withstand 121℃ high temperature sterilization process. The

packaging will not deform or release harmful substances during

processing such as steaming and baking, providing reliable

protection for ready-to-eat foods, canned foods, etc.

Environmental advantages: a green choice that is recyclable

throughout the entire cycle

1,100% metal is recyclable: the base material is made of steel,

which can be completely recycled after being discarded. The surface

film layer is decomposed into harmless oxides during the smelting

process, which does not affect the quality of recycled steel, and

the recycling rate is far higher than that of plastics, glass and

other materials.

2,Low-carbon production mode: the process energy consumption is 15%

lower than that of traditional tinplate, and the entire life cycle

from production to disposal is more environmentally friendly, which

is in line with the global "carbon neutrality" trend and helps

brands fulfill their green packaging commitments.

Application scenarios: packaging innovation adapted to multiple

fields

1,Beverages and dairy products: used in cola cans, milk powder

cans, etc., resistant to carbonic acid corrosion and strong

sealing, extending the shelf life of beverages;

2,Snack foods and condiments: made into potato chip barrels, soy

sauce bottles, etc., moisture-proof and anti-oxidation, maintaining

a crisp taste and flavor;

3,High-temperature processed foods: competent for luncheon meat

cans and instant porridge packaging, and can still maintain

packaging integrity after high-temperature sterilization.

Three reasons to choose Tin Free Steel

1,Safety: No risk of heavy metal migration, passed multiple food

contact safety certifications at home and abroad;

2,Reliable performance: Barrier properties are comparable to

traditional tinplate, while also having better processing and

forming properties;

3,Environmental protection bonus: Recyclable properties help brands

meet the green packaging standards of supermarkets and e-commerce

platforms, and enhance consumer trust.

- Free samples provide.

- 20 years experience technicial support.

- Service always available .

- 1st grade material for every production.

- Original cost for your separated purchase.

PARTNER

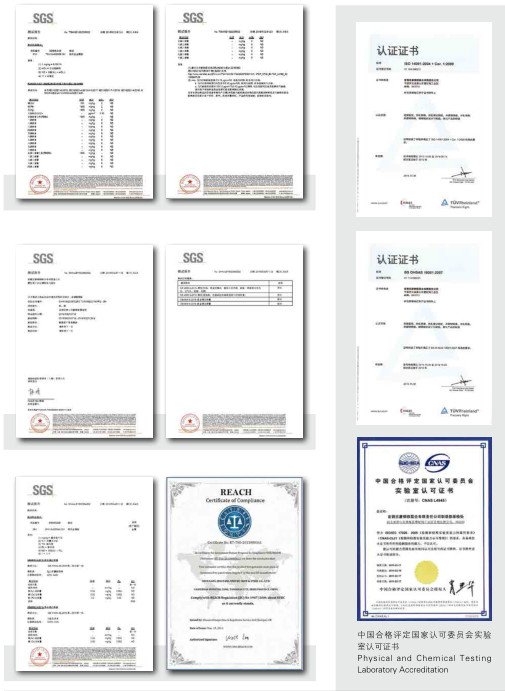

CERTIFICATE

Information Required with orders and inquirys

Orders and inquiried shall be accompanied by the following

information.

1. products name and grade

2.coaing and mass( for Tinplate only),temper grade,finish, and

products size.

3.rolling direction

4.quantity

5.application and delivery date

6.number of sheets per packaging( for cut to length products)

7.inside diameter amd maximum acceptable unit coil weight (for

coils products).

8.film type,color, contents,and other details of use and

environment.

9.other special requirements,if any.