| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Metal Crusher |

|---|---|

| Brand Name: | Xrido |

| Model Number: | Customizable |

| Certification: | CE ISO |

| MOQ: | 1 set |

| Payment Terms: | Negotiable |

| Delivery Time: | 2-32 work days |

| place of origin: | Henan, China |

| video outgoing-inspection: | Provided |

| machinery test report: | Provided |

| core components: | PLC, Engine, motor |

| brand name: | Xrido |

| warranty: | 1 Year |

| material / metal processed: | Stainless Steel, Brass / Copper, Alloy, Carbon Steel, Aluminum |

| key selling points: | Multifunctional |

| Application: | Scrap Cable Recycling |

| Name: | Scrap Metal Crusher Machine |

| Keyword: | Scrap Metal Shredder Line |

| Final product: | 1-10 Cm |

| Function: | Recycle Metal |

| Warranty: | 12 Months |

| Advantage: | 99% Separate Purity |

| Color: | Customer's Requirement |

| Company Info. |

| Henan Xrido Environmetal Protection Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

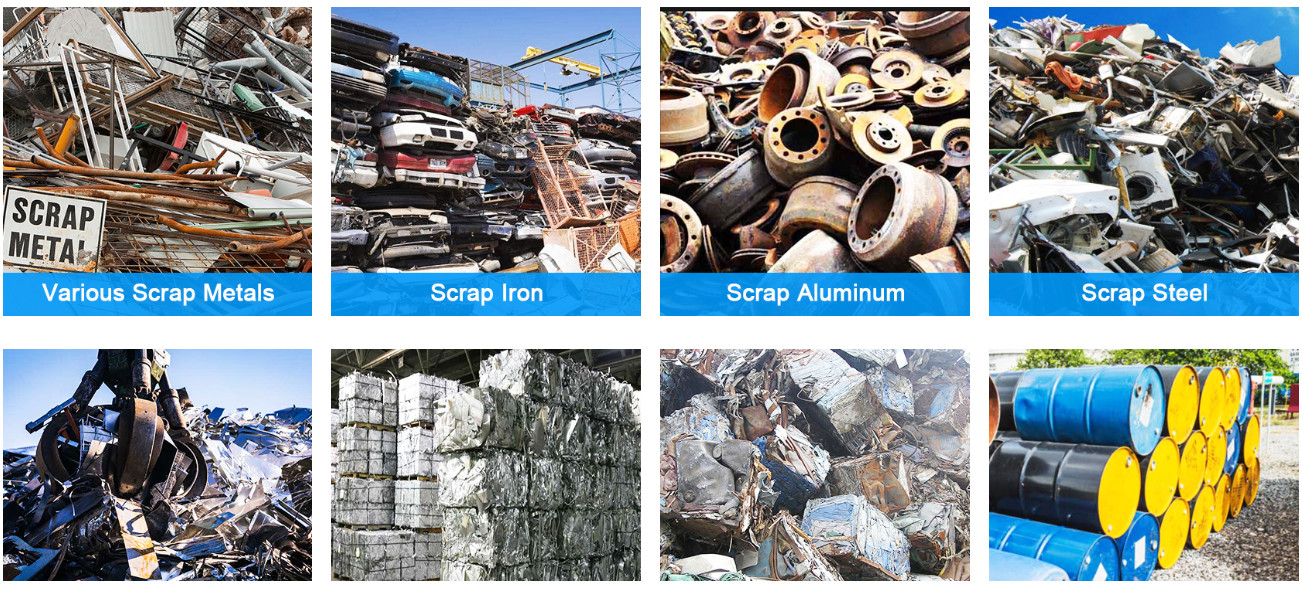

Applicable materials for scrap steel/aluminum/iron crushers:

Scrap steel: automobile shells, color steel tiles, steel bars, industrial scrap steel.

Scrap aluminum: aluminum alloy doors and windows, cans, aluminum home appliance parts.

Scrap iron: iron barrels, mechanical parts, construction waste.

Composite materials: metal-containing cables and circuit boards (pretreatment required).

model | voltage | accessory equipment | power(kw) | capacity(t/h) |

PSJ-140 | 380v | Feeding conveyor one Discharging conveyor one Iron conveyor one Impurity conveyor one Magnetic separation system one Dust removal system one Control system one Intelligent Visual System (Optional) one Sprinkler system (optional) one | 132 | 2-3 |

PSJ-200 | 380v | 200 | 3-5 | |

PSJ-280 | 380v | 280 | 4-7 | |

PSJ-315 | 380v | 315 | 5-8 | |

PSJ-450 | 380v | 450 | 8-12 | |

PSJ-630 | 10kv | 630 | 10-15 | |

PSJ-750 | 10kv | 750 | 12-17 | |

PSJ-800 | 10kv | 800 | 15-20 | |

PSJ-900 | 10kv | 900 | 20-30 | |

1500HP | 10kv | 1200 | 25-40 | |

2000HP | 10kv | 1500 | 50-60 | |

3000HP | 10kv | 2250 | 60-80 | |

4000HP | 10kv | 3000 | 80-100 | |

6000HP | 10kv | 4420 | 100-160 | |

8000HP | 10kv | 6000 | 160-200 | |

10000HP | 10kv | 7500 | 200-26 |

|

|

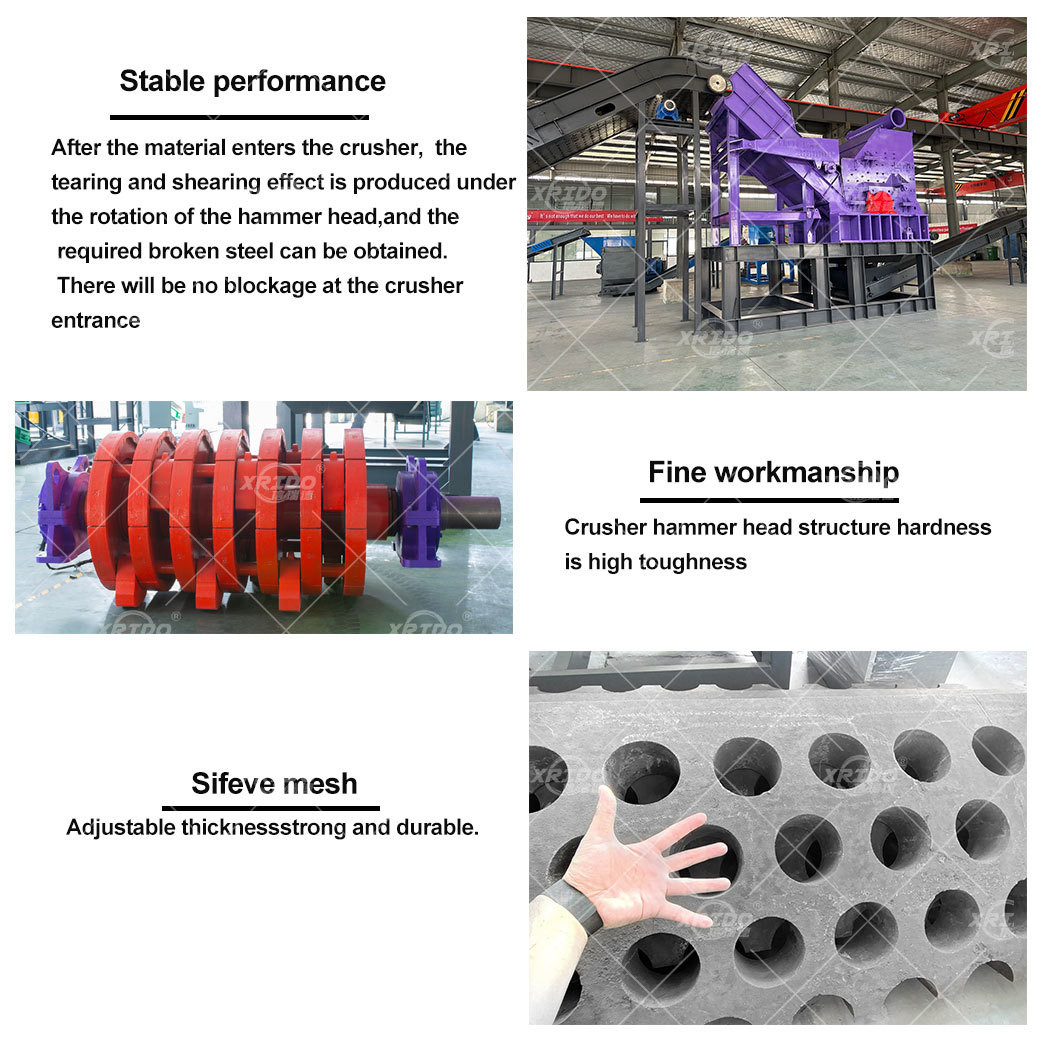

Function and application of the equipment

The scrap aluminum crusher can efficiently separate

aluminum-containing materials, such as aluminum chips and aluminum

alloys, and achieve a high sorting rate through electrostatic and

specific gravity separators. It is an ideal equipment for scrap

aluminum recycling.

High sorting rate

The scrap aluminum crusher has a sorting rate of up to 96-99%,

which can ensure efficient recycling of aluminum.

Key parameters and design

After long-term use, if the moving knife is naturally worn or

damaged, the moving knife can be easily replaced. At the same time,

other key parameters of the equipment, such as the high-alloy steel

blades, specific blade diameters and blade thickness designs, are

optimized during the manufacturing process to improve the service

life and efficiency of the equipment.

Reliable and durable recycling technologies for material separation and recovery,treatment of various types of solid waste and metal scrap. Metal recycling can benefit your Enhance and economic value , Help you improve recycling eliminate landfilling of waste.

With XRIDO’s ready-to-use spare parts library , you gain peace of mind through seamless maintenance and reduced downtime.

|

|

|

|

Process flow of scrap steel/aluminum/iron crushers recycling line:

Pretreatment: remove non-metallic attachments such as liquids and plastics from metal materials.

Crushing: the material enters the crushing chamber and is crushed at high speed by a hammer or a cutter disc.

Sorting: magnetic separation of ferrous metals, eddy current separation of

non-ferrous metals (such as aluminum and copper).

Discharge: Pure metal crushed materials are transported to the baler or

shipped directly.

|