| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | PEEK Machined Parts |

|---|---|

| Brand Name: | ruiyihang |

| Place of Origin: | China |

| MOQ: | 5PCS |

| Price: | USD5.1~19.1/PCS |

| Delivery Time: | 5-8 works |

| Packaging Details: | Plastic trays and carton |

| Company Info. |

| Shenzhen ruiyihang technology co., ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

PEEK (polyetheretherketone) is a high-performance thermoplastic that is highly favored in the engineering field for its outstanding mechanical strength, high-temperature resistance, chemical inertness, and self-lubricating properties. Through CNC machining, PEEK components can operate stably for long periods in harsh environments and are widely used in demanding industries such as aerospace, medical, semiconductor, and petrochemical.

1. Material Advantages

2. Diverse processing materials and procedures

| Machining Process | CNC Milling,CNC Turning,Sheet Metal Fabrication. |

| CNC Machining Materials | Aluminum 6061, 6063, 6061-T6, 7075, 5052, 2017, 6083. Steel: Q215, Q235, 10#, 15#, 45#, S136, SKD11, 718H. copper / bronze / Titanium / TC4. Plastic: Delrin POM, Teflon, Nylon, PA, PC, PMMA, Ultem, PEI, PTFE. Stainless steel: 303, 304, 316, 430, 420. Secondary Services Offered: laser engraving LOGO, Anodizing, Plating Chrome, Nickel, RoHS Zin, Assembly Welding, Heat Treating, Powder Coating, Centerless Grinding. |

| CNC Machining equipment | NC machining center, CNC turning center, engine lathe, drill press, milling machine, grind machine |

| Surface Treatment | anodize (black, blue, yellow, a variety of custom colors), sandblasting, dusting, chemical plating, and laser engraving LOGO |

3. Highly efficient and precise processing capabilities

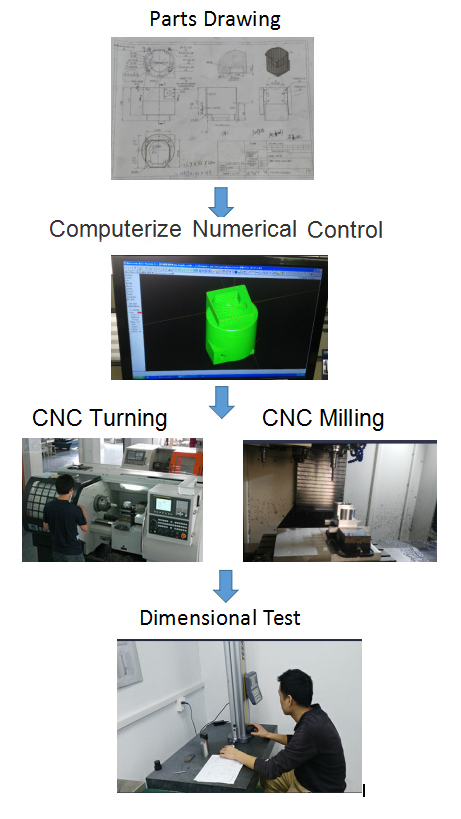

We are equipped with a variety of precision processing equipment, including CNC machining centers (three-axis and four-axis), CNC lathes, ordinary lathes, CNC turning centers, 8/12 station hydraulic tool towers, milling machines, grinding machines, drilling machines, tapping centers, rotary positioners and presses, which fully support the efficient manufacturing of complex structures and high-precision parts.

4. Common application fields of PEEK parts

5. From raw materials to finished products, we offer a truly comprehensive service to meet all your processing requirements.

|