| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Drilling Rig Tool |

|---|---|

| Brand Name: | APIE |

| Model Number: | 600-3000mm or as required |

| Certification: | CE and ISO9001 |

| Place of Origin: | Jiangsu, China |

| MOQ: | 1 sets |

| Price: | $1000+ |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram |

| Supply Ability: | 200 Unit/Units per Month |

| Delivery Time: | 3-5 days after payment |

| Packaging Details: | Wood case outside, plastic cases inside |

| Product name: | Core Barrel with bullet teeth |

| Application: | Foundation Piling |

| Material: | High Manganese Steel |

| Processing Type: | Welding |

| Advantage: | Strong Compatibility |

| Color: | Request |

| Feature: | bullet teeth scratch rocks |

| MOQ: | 1 Piece |

| Company Info. |

| APIE FOUNDATION EQUIPMENT (CHINA)LIMITED |

| Verified Supplier |

| View Contact Details |

| Product List |

Wide-Ranging Applications:

Our rotary rig tools are crafted to handle a variety of difficult

geological conditions, such as:

Drill Bit Piles:

These tools are engineered to penetrate tough formations, ensuring

exceptional durability and performance. They are perfect for

navigating challenging rock layers and achieving accurate drilling

outcomes.

Bullet Teeth:

Our bullet teeth are designed for optimal rock scratching and

breaking, enhancing drilling efficiency in challenging

environments. They provide superior cutting capabilities and

longevity, maximizing productivity.

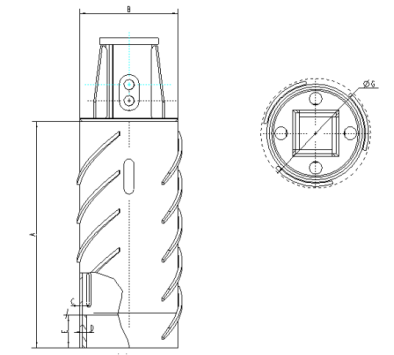

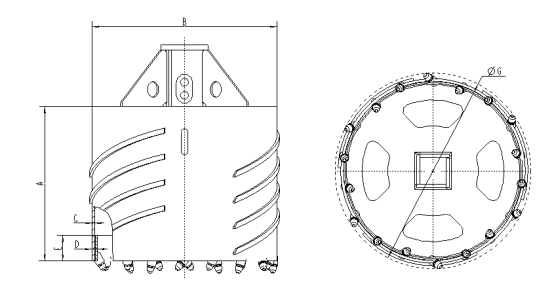

Core Barrel:

This versatile tool is adept at creating annular rings in various

materials, including rock, concrete, and reinforced concrete. It

effectively channels torque and crowd force to a concentrated area

of cutting teeth, facilitating precise drilling.

Drilling Bucket:

Specifically tailored for soil and soft rock conditions, our

drilling buckets utilize friction Kelly bars to minimize slippage,

demonstrating excellent performance across diverse drilling

scenarios.

Product Details

| Technical Specification of core barrel with bullet teeth | |||||

| drilling Dia. | Shell HIT. | Shell Thickness | Stiffening Ring THK. | Teeth.No. | Weight |

| (mm) | (mm) | (mm) | (mm) | (number) | (kg) |

| 600 | 1200 | 16 | 20 | 6 | 540 |

| 800 | 1200 | 16 | 20 | 9 | 690 |

| 900 | 1200 | 16 | 20 | 10 | 750 |

| 1000 | 1200 | 16 | 20 | 11 | 870 |

| 1200 | 1200 | 16 | 20 | 13 | 1020 |

| 1500 | 1200 | 16 | 20 | 16 | 1400 |

| 1600 | 1200 | 16 | 20 | 17 | 1530 |

| 1800 | 1000 | 20 | 20 | 19 | 1860 |

| 2000 | 800 | 20 | 20 | 21 | 1870 |

| 2200 | 800 | 20 | 20 | 23 | 2400 |

| 2500 | 800 | 20 | 20 | 27 | 2705 |

| 2800 | 800 | 20 | 20 | 30 | 3200 |

| 3000 | 800 | 20 | 20 | 32 | 3800 |

When choosing the appropriate bullet teeth for core barrels and drill bucket augers, consider the following:

Geological Factors:

The type of bore pile required will largely dictate your selection.

Outer Diameter (OD) of Drill Buckets or Augers:

Knowledgeable manufacturers can offer tailored recommendations

based on the specifics of your project.

FAQ

1: How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment

2: What can you buy from us?

Rotary Drilling Rig,Hydraulic Pile Breaker,Clamshell Telescopic

Arm, drilling tools

3: What's your service ?

We can offer professional technical support and good after-sale

service to you.

Modification methods will be different according to different

models and configurations of your owned excavators.

Before modifying, you need to provide configuration, mechanical and

hydraulic joints and others.

Before modifying, you need to confirm technical specification.

|