| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Precision CNC Components |

|---|---|

| Brand Name: | JIMAFor |

| Certification: | AS9100, IATF1 |

| Place of Origin: | CHINA |

| MOQ: | 1PCS |

| Price: | Negotiations |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 2000 MT per month |

| Delivery Time: | 10~25days |

| Packaging Details: | Standard Export Package |

| Name: | 8-inch wafer transfer 6063 aluminum alloy guide rail |

| Material: | 6063 |

| Application: | Semiconductor wafer transfer guide rail,Semiconductor Wafer Transfer Equipment |

| Size: | Size,/material/sample/customisation |

| Processing: | CNC Machining, Surface treatment |

| Company Info. |

| JimaFor |

| Verified Supplier |

| View Contact Details |

| Product List |

8-Inch Wafer Transfer 6063 Aluminum Alloy Guide Rail ,Wafer Transfer Rail

7075 aluminium alloy is ideally suited for the manufacture of semiconductor wafer transfer guides due to its high strength, good corrosion resistance, low density and excellent machinability. Its performance can be further enhanced by appropriate heat treatment and surface treatment to meet the stringent requirements for precision and reliability in semiconductor manufacturing.

OUR Products including :

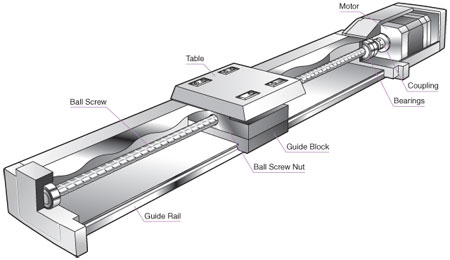

Precision CNC Components for Semiconductor Wafer Transfer Guides

High Precision and Customized for Corrosion Resistance

Precision CNC Components for Semiconductor Wafer Transfer Guides

and Customized for Semiconductor Wafer Transfer Guides

Precision CNC Components for Semiconductor Wafer Transfer Guides

and Customized for Semiconductor Wafer Transfer Guide Rail

Precision CNC Components for Semiconductor Wafer Transfer Guides

High Strength and Customized for Repeat Positioning Accuracy

Precision CNC Components for Semiconductor Wafer Transfer Guides

and Customized for Grinding Wire Cutting and Precision Milling

Size,/material/sample: customisation

Processes:

1.High precision machining: Extrusion

2.Surface treatment: In order to improve wear resistance and corrosion resistance, the

guideway surface is often anodised, hard chrome plated or nitrided.

3. Assembly and commissioning: guide rail assembly needs to be precisely adjusted parallelism

and straightness, to ensure smooth movement, reduce vibration and

error.

Products Advantages:

- High strength and light weight: The high strength and low density characteristics of 6063

aluminium alloy make it an ideal material for manufacturing

semiconductor wafer transfer guides, reducing equipment weight

while ensuring structural strength.

- Good wear resistance: Its good wear resistance ensures the long-term stability of the

guideway in frequent use, reducing the frequency of maintenance and

replacement.

- Corrosion resistance: In semiconductor manufacturing environments, the corrosion

resistance of 6063 aluminium alloy helps to resist the erosion of

various chemicals, ensuring the normal operation of equipment

- High-precision machinability: The machinability of 6063 aluminium alloy enables it to meet the

high precision and complex shape requirements of semiconductor

wafer transfer guides.

- Precision CNC Machining

Application

Used for Semiconductor Wafer Transfer Equipment

|