| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Vibratory Screening Machine |

|---|---|

| Brand Name: | EVERSUN |

| Model Number: | EXZS |

| Certification: | ISO,CE |

| Place of Origin: | CHINA |

| MOQ: | 1set |

| Price: | negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, MoneyGram, Western Union |

| Supply Ability: | 5000set/year |

| Delivery Time: | within 7-15 work days |

| Packaging Details: | Standard export wooden cases |

| Frequency: | adjustable |

| Dimension: | Customized |

| Installation Method: | Floor-mounted or suspended |

| Power: | 0.55-3Kw |

| Support Structure: | Carbon steel or Stainless Steel |

| Number Of Layers: | 1-5 |

| Mesh Size: | 2-500mesh |

| Screen Mesh: | 20-200 Mesh |

| Vibration Frequency: | Adjustable |

| Screening Motion: | Circular, elliptical, or linear |

| Feature: | High Screening Efficiency |

| Company Info. |

| EVERSUN Machinery (Henan) Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Product description

The rotary vibrating screen is a highly efficient and precise screening equipment. The main body is driven by a vertical motor as the excitation source. The eccentric weights installed at the upper and lower ends of the motor can convert the rotational motion into three-dimensional motion in the horizontal, vertical and inclined directions and transmit it to the screen surface. Its screen surface is cylindrical. Through the superimposition of multiple layers of screens, it can classify or screen different materials such as granules, powders, and viscous liquids. It features high screening accuracy, large processing capacity, compact structure, easy installation and maintenance, etc. It is widely used in industries such as chemical engineering, food, medicine, metallurgy, and building materials, effectively separating impurities, controlling particle size, and improving material quality and production efficiency.

Working principle

The working principle of the rotary vibrating screen is that the

vertical vibrating motor drives the eccentric weights at the upper

and lower ends, causing the screen surface to generate

three-dimensional compound vibrations in the horizontal, vertical

and inclined directions. The material forms a spiral parabolic

motion trajectory on the screen surface. Fine particles fall layer

by layer through the corresponding pore size screen, while coarse

particles are discharged along the edge of the screen. By adjusting

the phase Angle of the heavy hammer, the vibration amplitude and

the movement speed of the material can be changed, achieving

precise classification of materials of different particle sizes. It

features high efficiency, flexibility and wide application range,

and is widely used in screening operations in the fields of

chemical engineering, food, medicine, etc.

Features & Benefits

①Three-dimensional vibration and spiral movement of materials

result in a screening efficiency 30% higher than that of

traditional equipment.

② Multi-layer classification: 1 to 5 layers of screens can complete

the screening of 2 to 6 different specifications at one time.

③ The parameters are adjustable. The amplitude and frequency can be

controlled by the weight hammer to adapt to different materials.

④ Quick-release design, the screen can be replaced within 10

minutes, making maintenance convenient.

⑤ Low consumption and stable, with energy consumption reduced by

20% and noise ≤75dB.

⑥ Diverse materials are available. The stainless steel body meets the standards of food and medicine, and the net cleaning device prevents clogging.

Product parameter

| Model | Equipment diameter | Power(KW) | Deck | Effective screening area(m2) | Screen mesh |

| EXZS-600 | 600mm/24inch | 0.25 | 1-5 | 0.2289 | 20 microns to 20 mm |

| EXZS-800 | 800mm/32inch | 0.55 | 0.4183 | ||

| EXZS-1000 | 1000mm/40inch | 0.75 | 0.6359 | ||

| EXZS-1200 | 1200mm/48inch | 1.1 | 0.9499 | ||

| EXZS-1500 | 1500mm/60inch | 1.5 | 1.5386 | ||

| EXZS-1800 | 1800mm/70inch | 3 | 1-4 | 2.2687 | |

| EXZS-2000 | 2000mm/78inch | 4.5 | 2.8893 |

Design Drawing Display

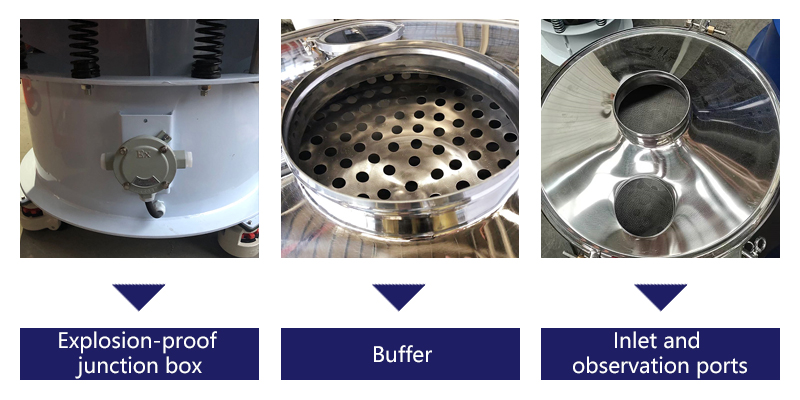

Detail display

Application

Packaging & Shipping

Why Choose us

About us

We have been specializing in the production of Screening and

conveying equipment for 13 years. China's vibrating screen industry top three. And we have done

matching and OEM for many large companies. Including the world's top vibrating screen manufacturer,

Sweco, USA, we have OEM

for his China region. And our products are often exported to

Australia, Thailand, Indonesia, New Zealand and other countries.

We welcome customers or dealers to visit our factory and will

arrange everything for you.Our factory address: West of the industrial and commercial office of Da

Zhaoying Town, Xinxiang City, Henan Province.

|