| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Longitudinal Finned Tube |

|---|---|

| Brand Name: | Yuhong |

| Model Number: | ASTM A312 TP316L Longitudinal Finned Tubes |

| Certification: | ABS, BV, DNV, CCS, LR |

| Place of Origin: | China |

| MOQ: | 1ton |

| Price: | Negotiable |

| Payment Terms: | TT, LC |

| Supply Ability: | 1000 tons/month |

| Delivery Time: | 70-90 days |

| Packaging Details: | Ply-wooden Case With Iron Frame |

| Product: | Fin Tubes or Finned Tube |

| Finned Tubes Type: | Longitudinal Finned Tubes |

| Base Tubes Standard: | ASTM A312 |

| Longitudinal Finned Tubes Material: | TP316L Welded pipes and Stainless Steel Fins |

| Longitudinal Finned Tubes Length: | According to clients' need |

| Longitudinal Finned Tubes Size and details: | According to clients' need |

| Longitudinal Finned Tubes Use: | Heat Exchanger / Boiler / Furnaces / Condensers / Evaporators, etc |

| Longitudinal Finned Tubes Packing: | Ply-wooden Case With Iron Frame |

| Company Info. |

| YUHONG HOLDING GROUP CO., LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

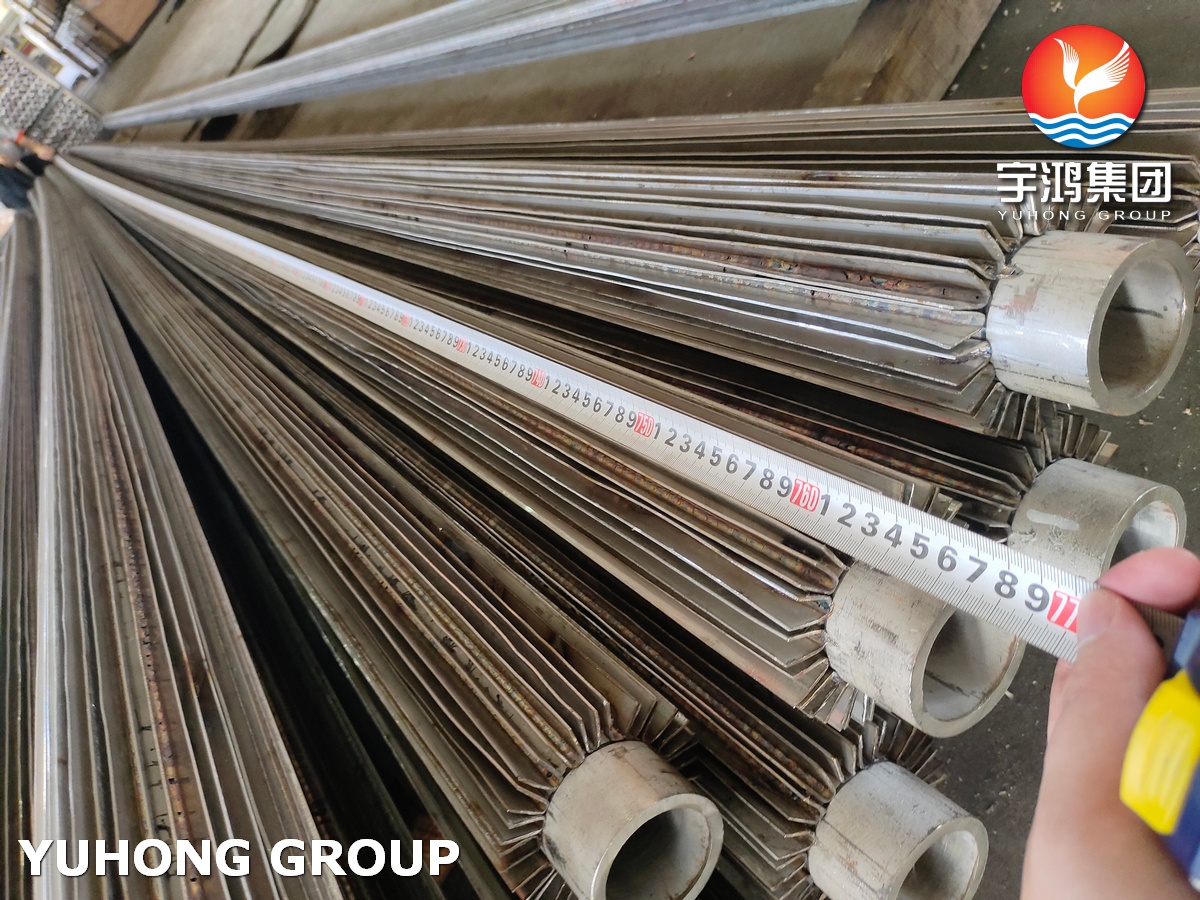

Welded Longitudinal Finned Tubes ASTM A312 TP316L For Oil Refining Projects

ASTM A312, a standard of seamless, straight-seam welded, and heavily cold worked welded austenitic stainless steel pipe, intending for high-temperature and general corrosive service. Welded TP316L stainless steel tubes have the following core performance advantages:

Chemical Composition (%)

| Grade | C | Mn | P | S | Si | Cr | Ni | Mo |

| TP316L S31603 | 0.035 | 2.00 | 0.045 | 0.030 | 1.00 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 |

For small diameter or thin walls or both, where many drawing passes are required, a carbon maximum of 0.040% is necessary in grades TP304L and TP316L. Small outside diameter tubes are defined as those less than 0.500 in. [12.7 mm] in outside diameter and light wall tubes as those less than 0.049 in. [1.20 mm] in average wall thickness (0.044 in. [1.10 mm] in minimum wall thickness).

Mechanical Properties

| Grade | Tensile Strength,min | Yield Strength (0.2%Offset,min) | Elongation min. | Heat treatment |

| TP316L | 70ksi (485 MPa) | 25ksi (170 MPa) | 35% | 1900°F [1040°C] |

Tests:Transverse or Longitudinal Tension Test, Flattening Test, Grain Size, Flaring Test, Flange Test, Hardness Test, Hydrostatic Test or Nondestructive Electric Test.

Manufacture:Welded (WLD) pipe shall be made using an automatic welding process with no addition of filler metal during the welding process.

Surface Condition:The pipe shall be free of scale and contaminating exogenous iron particles. Pickling, blasting, or surface finishing is not mandatory when pipe is bright annealed. The purchaser is permitted to require that a passivating treatment be applied to the finished pipe.

Definition

Longitudinal finned tubes are produced by resistance welding fins along the long direction of the tube and fins first form a U-shaped channel so that each leg of the U-shape forms a fin.

Common base pipe/tube material: carbon / alloy steel (A106, A333, A179, A335 P5, P22, P9, etc.; stainless steel TP304, TP316L,TP321, etc.;copper alloy CuNi 70/30, CuNi 90/10, etc and other material.

Advantages in Oil Refining

Corrosion & Temperature Resistance

• Resists acidic crudes/sour gases: Mo content mitigates pitting in

HCl/H₂S-rich streams (e.g., crude distillation overhead

condensers).

• High-temp stability: Continuous service up to 870°C, which is

ideal for fired heater convection sections.

Heat Transfer Efficiency

• 3–5× surface area vs. bare tubes, enhanced radiant heat

absorption and delays coking on tube walls.

• Axial flow optimization: Reduces pressure drop in viscous fluids

.

Application

Longitudinal finned tubes are widely used in industries where axial flow heat transfer, high-temperature stability, and corrosion resistance are critical.Generally applicable to power stations or large high-temperature old equipment in the oil industry:

Oil & Gas Refining

*Crude Oil Processing:Charge Gas Heaters / Overhead Condensers /

Delayed Cokers.

*Hydroprocessing & FCC Units: Feed/Effluent Exchangers / Flue Gas

Coolers.

*Sulfur Recovery (SRU):Waste Heat Boilers.

Petrochemical & Chemical Plants

*Ethylene Crackers / Reformer Furnaces / Polymer Reactors.

Power Generation

*Heat Recovery Steam Generators (HRSG) / Flue Gas Desulfurization

(FGD) / Gas Turbine Inlet Air Cooling.

LNG & Cryogenic Applications

*LNG Heat Exchangers / BOG (Boil-Off Gas) Compressors.

HVAC & Industrial Heating

*Thermal Oil Heaters / Hot Air Generators.

Specialty Applications

*Solar Thermal Systems / Nuclear Reactors.

Typical Oil Refining Applications

| Unit | Application | Key Benefit |

| Crude Distillation | Overhead condensers | HCl corrosion resistance |

| Delayed Coking | Heater tubes (convection section) | Reduced coking fouling |

| Hydroprocessing | Feed/effluent exchangers | H₂S/H₂ corrosion protection |

| FCC | Regenerator flue gas coolers | Erosion resistance |

| Sulfur Recovery (SRU) | Waste heat boiler tubes | Acid dew point corrosion mitigation |

Specifications For Various Types Of Finned Tubes

| Type | Description | Base tube | Fin specification (mm) | ||

| O.D. (mm) | Fin pitch | Fin height | Fin thick | ||

| Embedded | G-type fin tube | 16-63 | 2.1~5 | <17 | ~0.4 |

| Extruded | Single metal / Combined metal | 8-51 | 1.6~10 | <17 | 0.2-0.4 |

| Low fin tube / T-type fin tube | 10-38 | 0.6~2 | <1.6 | ~0.3 | |

| Bamboo tube / corrugated tube | 16-51 | 8.0~30 | <2.5 | ~0.3 | |

| Wound | L / KL / LL type fin tube | 16-63 | 2.1~5 | <17 | ~0.4 |

| String | String fin tube | 25-38 | 2.1-3.5 | <20 | 0.2-0.5 |

| U-type | U-type fin tube | 16-38 | / | / | / |

| Welding | HF-welding fin tube | 16-219 | 3~25 | 5~30 | 0.8-3 |

| H/HH type fin tube | 25-63 | 8~30 | <200 | 1.5-3.5 | |

| Studed fin tube | 25-219 | 8~30 | 5~35 | φ5-20 | |

|