| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Planetary Ball Mill |

|---|---|

| Brand Name: | TENCAN |

| Model Number: | XQM-60L |

| Certification: | CE ISO |

| Place of Origin: | Hunan, China |

| MOQ: | 1 Set |

| Price: | Negotiable |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 100 sets per month |

| Delivery Time: | 25-35 working days |

| Packaging Details: | Plywood Case+Foam |

| Product Name: | Production Type Planetary Ball Mill |

| Model No.: | XQM-60 |

| Total Volume: | 60L |

| Max Capacity: | 19.8L |

| Rotate Speed: | 40-240 rpm |

| Speed Control: | Frequency Control |

| Voltage: | 380V-50Hz |

| Power: | 7.5KW |

| Company Info. |

| Changsha Tianchuang Powder Technology Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

60L Industrial-Grade Planetary Ball Mill - High-Power Nano Grinding System

Next-Generation Material Processing Solution

Our 60L vertical planetary ball mill represents the pinnacle of industrial-scale powder processing technology, combining robust 7.5KW 380V motor power with precision nano-grinding capabilities. This professional-grade system is engineered to meet the most demanding production requirements while maintaining laboratory-level accuracy in particle size reduction.

Advanced Grinding Dynamics

The mill's innovative vertical planetary mechanism creates a multi-dimensional grinding environment where four large-capacity jars execute complex synchronized movements. This unique motion pattern generates balanced centrifugal forces up to 20G, achieving consistent particle refinement to 100 nanometers with industrial-scale reproducibility. The vertical configuration enhances energy transfer efficiency by 30% compared to conventional designs.

Key Industrial Applications

This production-grade system excels in:

Battery material manufacturing (cathode/anode powders)

Advanced ceramic production (structural/functional components)

Electronic material preparation (MLCC, ferrites, varistors)

Pharmaceutical intermediate processing (API micronization)

Nanocomposite fabrication (graphene hybrids, quantum dots)

Technical Superiority

High-Torque Motor System: 7.5KW 380V industrial powerplant

Precision Planetary Drive: ±0.8% speed consistency

Intelligent Process Control: Programmable multi-stage operation

Enhanced Safety Systems: Mechanical/electrical protection

Large Capacity Processing: 60L total volume capacity

Material Versatility: Dry/wet grinding capability

Special Atmosphere Options: Vacuum/inert gas compatible

Performance Advantages

The system's vertical design delivers superior energy efficiency while maintaining vibration-free operation at full capacity. Advanced noise reduction technology keeps operational levels below 70dB, making it suitable for factory floor environments. The intuitive interface allows precise programming of complex grinding parameters.

Operational Benefits

Manufacturing facilities gain:

Seamless scale-up from lab to production

Consistent nano-scale particle quality

Reduced processing time through high-efficiency design

Lower operational costs via energy-optimized performance

Flexible configuration for diverse material requirements

This industrial ball mill solution combines production-scale capacity with precision grinding performance, making it ideal for advanced material manufacturers requiring reliable, high-volume nano powder processing capabilities.

Technical Features

| Technical Features | |

| Drive Mode | Gear drive and belt drive |

| Operate Mode | Two or four grinding tanks working together |

| Maximum Loading Capacity | 2/3 of the capacity of milling tank |

| Feeding Size | Soil material≤3mm |

| Output Granularity | Minimum 0.1μm |

| Rotational Speed Ratio | /1/2 |

| Max.Continuous Operating Time | 72hours |

| Materials of Jar | stainless steel.agate,nylon,corundum,zirconia,etc |

Technical Parameters

| Main Parameters of Vertical Industrial Planetary Mill Ball (SquareType) | |||||

| Model | Power(KW) | Voltage | Dimension(mm) | Revolution Speed (rpm) | Rotation Speed (rpm) |

| XQM-20 | 4 | 380V-50Hz | 1200*750*920 | 25-215 | 50-430 |

| XQM-40 | 5.5 | 380V-50Hz | 1400*850*1160 | 20-195 | 40-390 |

| XQM-60 | 7.5 | 380V-50Hz | 1600*990*1250 | 27-174 | 40-260 |

| XQM-100 | 11 | 380V-50Hz | 1750*1140*1330 | 27-160 | 40-240 |

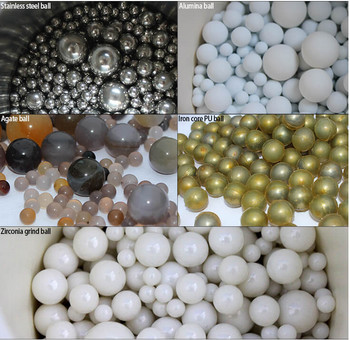

Accessories of Mill Jars & Balls

Available Mill Jars:

304 stainless steel mill jar, 316 stainless steel mill jar, tungsten carbide mill jar, agate mill jar, alumina ceramic mill jar(also called corundum mill jar), zirconia mill jar, nylon mill jar, polyurethane mill jar, mill jar (PTFE), and etc.

Available Mill Balls:

304 stainless steel mill balls, 316 stainless steel mill balls, tungsten carbide mill balls, agate mill balls, alumina balls, zirconia mill balls, and etc.

|