Product Description

In terms of injection molded product quality:

High dimensional accuracy: Injection molds have relatively high

precision and can produce products with high dimensional accuracy

and small dimensional deviations. Generally speaking, the

dimensional deviation of precision injection molded products can be

controlled within 0.03mm or even smaller.

Good quality consistency: Under the same production conditions,

injection molded products have relatively good quality consistency,

which is very important in fields that require large-scale

production and have high product quality requirements. For example,

for injection molded products in fields such as automotive parts

and electronic equipment, quality consistency can ensure product

performance and reliability.

Good surface quality: The surface of injection molded products is

smooth and flat, with good appearance quality. By reasonable mold

design and control of injection molding process parameters, defects

such as flaws, scratches, and bubbles on the product surface can be

avoided.

Business Type | Manufacturer | Main Product | Plastic injection mold,Medical part mold,IML/IMD,2K injection

mold,Silicone rubber mold,Die casting,Prototype,CNC Milling, CNC

turning... | File Format | Solidworks,Pro/Engineer,Auto CAD,PDF,JPG,Sample | Plastic Material | HIPS ABS, PC, PP, PS, POM, PMMA,PE,AS,PPSN,PBT,PA66,PC/ABS.etc | Moulds' lead time | 20-35days,it depends on the product's size and structure | Bulk production lead time | 25-30days,it depends on the product's size and structure |

|

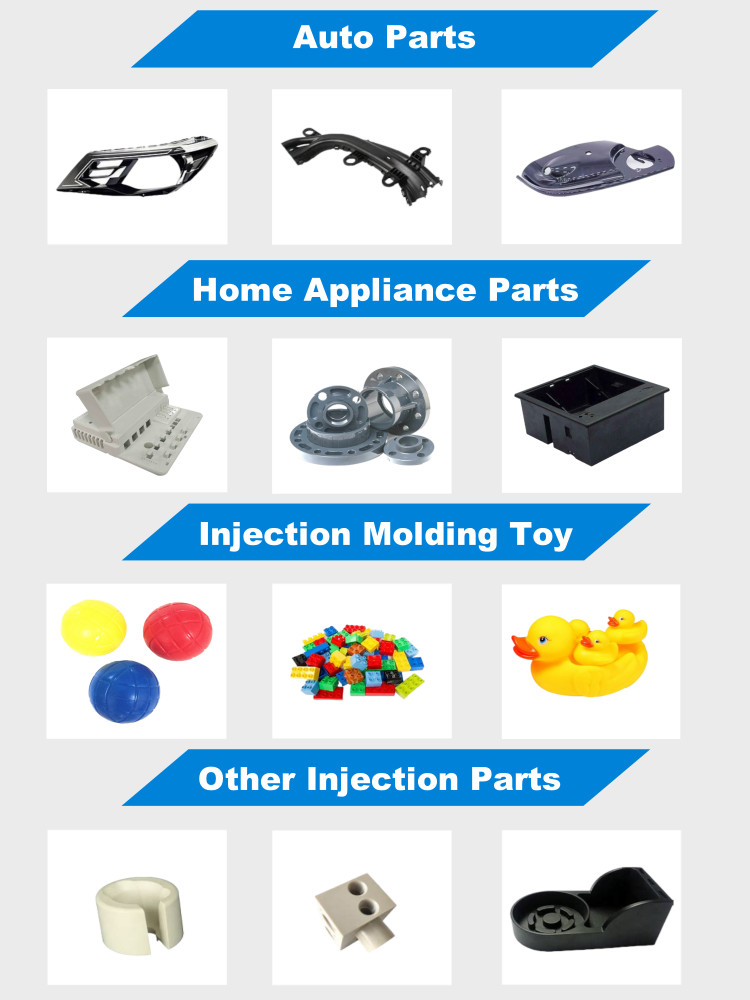

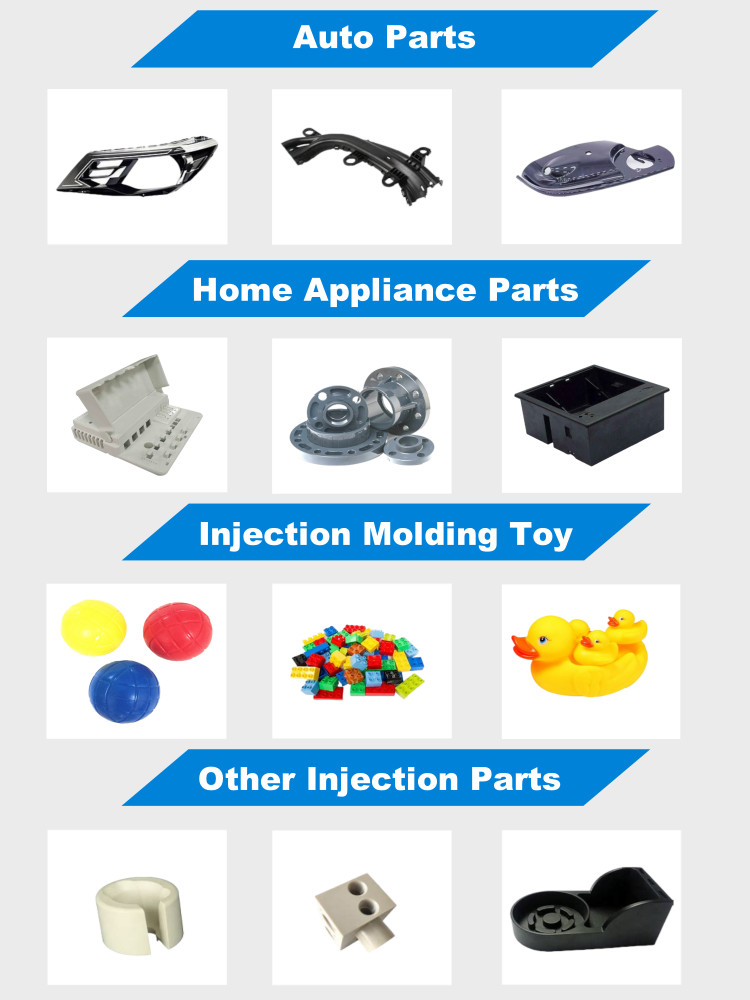

Product Display

FAQ

Q1: Where can I get product & price information?

A1: Send us e-mail , we will contact you as we receive your mail.

Q2: How soon can I get samples?

A2: Depending on your specific project, it usually takes 10 to 20

days.

Q3: How to enjoy the OEM services?

A3: Usually, base on your design drawings or original samples, we

give some technical proposals

and a quotation to you, after getting your agreement, we produce

for you.

Q4: Can you produce parts based on our samples?

A4: Yes, we can make measurement based on your samples to make

drawings for machining parts making.

Q5: Is it possible to know how are my products going on without

visiting your company?

A5: We will offer a detailed production schedule and send weekly

reports with digital pictures and videos which show the machining

progress.