| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Titanium CNC Machining |

|---|---|

| Brand Name: | Polestar |

| Model Number: | As Drawing |

| Certification: | ISO9001, TS16949 |

| Place of Origin: | China |

| MOQ: | 100pcs |

| Price: | According to the detailed drawing |

| Payment Terms: | L/C,D/A,D/P,T/T |

| Supply Ability: | 10000pcs per day |

| Delivery Time: | 3-20days |

| Packaging Details: | Carton + Pallet, Customized package is available |

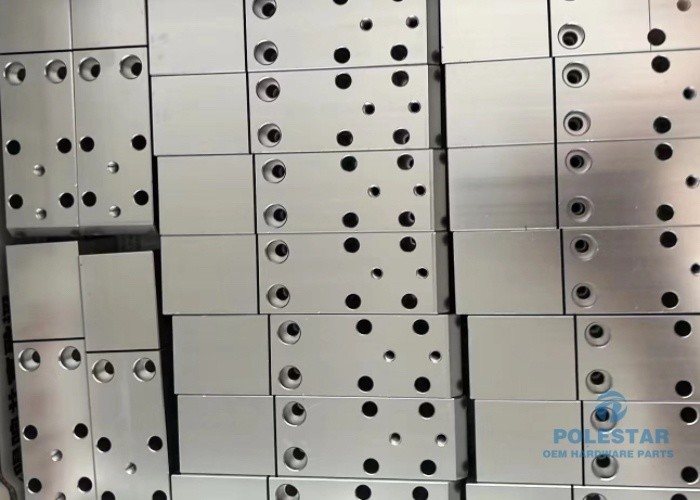

| Product name: | 5-Axis CNC Machining Parts |

| Material: | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys, Plastics |

| Technology: | 5-Axis Machining,Milling/Turning |

| Type: | Milling, Other Machining Services, Turning |

| Surface Treatment: | Anodizing , Plating |

| Quality Control: | Strict inspection before shipping |

| MOQ: | 100PCS |

| Drawing Format: | 2D/(PDF/CAD)3D(IGES/STEP) |

| Shipping: | Express, Air, Sea |

| Dimensions: | Customized Sizes |

| Company Info. |

| SUZHOU POLESTAR METAL PRODUCTS CO., LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

Titanium Alloy CNC Agricultural Machinery Variable Speed Gear Corrosion Resistant

Product Overview:

Adopting TC4 titanium alloy base material, it is both aerospace-grade strength and biocompatible, with a density of only 60% of steel, but with a tensile strength equivalent to high-strength steel (≥895MPa). The unique metal lattice structure forms a natural passivation film, which improves pitting resistance by more than 3 times compared to 316L stainless steel in a mixed acid/alkali/ salt farming environment, and it can comfortably cope with fertilizer residues, irrigation water rust, and continuous erosion by soil humus.

Product Details

| Aspect | Details | Advantages |

|---|---|---|

| Gear Types | - Spur gears - Helical gears - Bevel gears - Planetary gears | CNC can handle complex geometries for different transmission needs. |

| Material Used | - Alloy steel (20CrMnTi, 42CrMo) - Case-hardened steel - Ductile iron | High wear resistance and strength for heavy-duty applications. |

| CNC Processes | - Gear hobbing (for high-volume production) - Gear milling (for custom/low-volume) - Grinding (finishing, Ra ≤ 0.4μm) - Hard turning (post-heat treatment) | High precision (DIN 6-8 grade), repeatability, and flexibility. |

| Key Tolerances | - Tooth profile error: ≤0.01mm - Pitch error: ≤0.005mm - Surface roughness: Ra 0.8-1.6μm (after grinding) | Ensures smooth meshing, low noise, and long service life. |

| Tooling & Equipment | - Multi-axis CNC gear hobbing machines - CNC gear shaping machines - CNC grinders (e.g., KAPP, Gleason) - Carbide/ceramic cutting tools | High-speed machining (up to 4000 RPM), reduced cycle time. |

Scenario adaptation: the golden partner for a full range of agricultural machines

Tractor transmission systems: deep tillage, heavy-duty transportation, reducing corrosion due to

transmission fluid contamination

Combine harvester transmission: wet grain harvesting, straw crushing, resisting grain fermentation

acid erosion

Plant protection machinery gearbox: pesticide spraying, liquid fertilizer broadcasting, resistant to

strong corrosive liquid long-term contact

Drainage and irrigation machinery gear box: saline irrigation, sewage lifting, against high salt and high

chlorine water chemical corrosion

Why consider us?

No mold fees for aluminum profiles – We absorb these costs to reduce your expenses.

No welding fixture charges – Another way we help you save.

Combing different Producing Technology – Outsource Aluminium Profile, Shaped Metal, Metal Casting materials, MIM materials, then CNC machining to lower the unit price.

Cost-competitive production – Our lean manufacturing and expertise allow us to deliver high-quality parts at favorable prices.

One-Stop Factory – Our ISO9001 IATF16949 Certificated factory provide laser cutting, bending, Stamping, CNC Machining, Sheet Metal Working, welding, Assembling in one factory, ensure stable quality control.

|