| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Baby Pants Making Machine |

|---|---|

| Brand Name: | Womeng |

| Model Number: | WM-FTP10 |

| Certification: | CE |

| Place of Origin: | Fujian,China |

| MOQ: | 1 |

| Price: | $500,000.00-$800,000.00 |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram |

| Supply Ability: | 24sets/year |

| Delivery Time: | 80~120 Days |

| Packaging Details: | Seaworthy Wooden Box |

| Condition: | New |

| After-Sales Service Provided: | Engineers available to service machinery overseas |

| Control System: | PLC |

| Warranty: | 1 year |

| Operating Interface: | Touch Screen |

| Production Speed: | 500-600 pieces per minute |

| Packaging System: | Bagging and sealing |

| Color: | Customizable |

| Company Info. |

| Quanzhou Womeng Intelligent Equipment Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Product Description

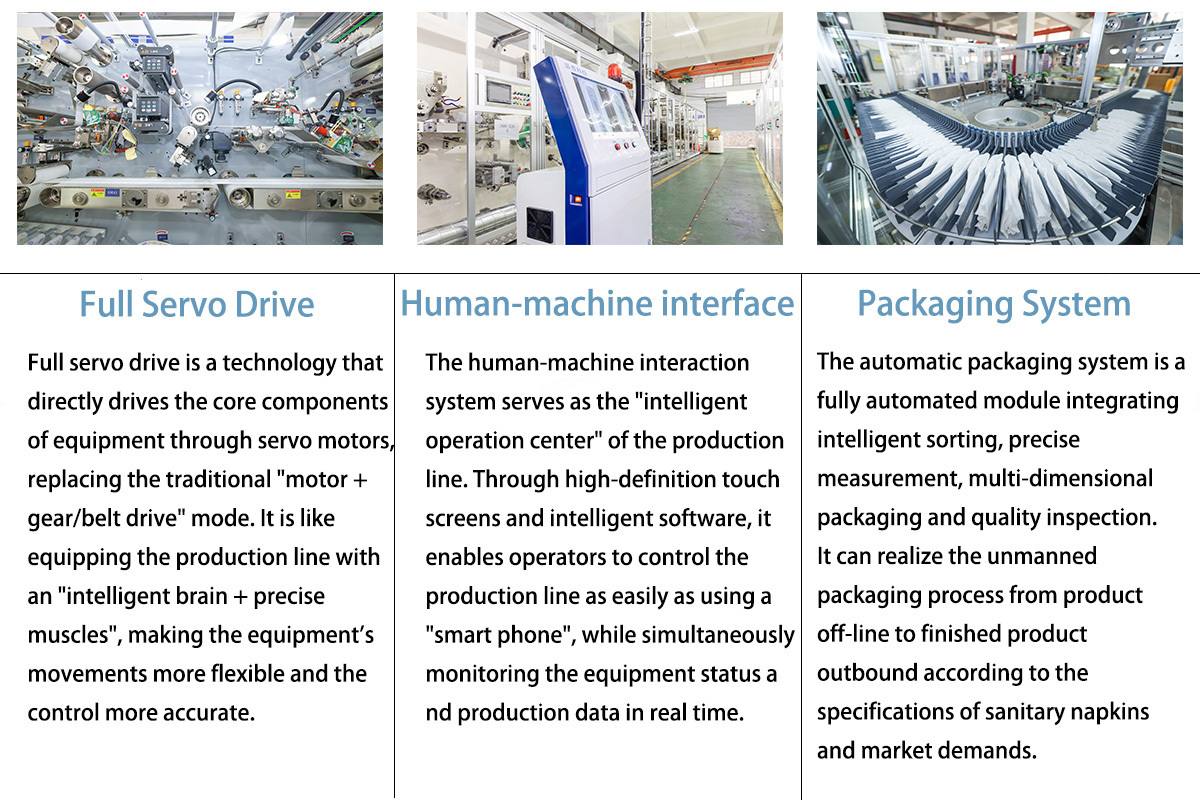

The production line of baby diapers runs efficiently and orderly. With advanced production equipment, its high degree of intelligence, remote monitoring and operation can be achieved. The production process is mature and constantly innovative, and the production speed is improved under the premise of ensuring the stability of product quality. With the help of scientific management mode, reasonable allocation of resources, give full play to the potential of equipment, and efficiently meet the diversified needs of consumers for baby diapers.

Product Info

Product size | 35m*6m*3m(for reference only) |

Product structure | Product structure: upper & lower tissue, cotton core (mix with SAP), cover sheet hydrophilic non-woven , ADL (Acquisitiondistribution layer) non-woven,leak guard hydrophobic non-woven back sheet,Waist band non-woven,color pattern sticker,elastic waist band, discarding sticker. |

Control system | PLC control system,HMI Operating on the LED touch screen,Configure

HDTV monitor |

Drive system | Semi Servo Drive, timing belt and flat belt are import products,

and all the key parts, are import bearings. |

Tension system | Top tissue paper,bottom tissue paper,hydrophobic nonwoven(leg

cuff),top nonwoven,ADL,back sheet,elastic nonwoven are adopt

A&B shaft active unwinding by inverter motor. |

Safety system | It has safety device on the operating side, matched with urgent

stop switch.High audio fan uses sound insulation or silencer. |

| Packaging system | according to customer requirements with palletizer machine (double push double exit ) adjustable |

Materials corrective system | Materials corrective system: Adopt international famous brand deviation correction system |

Power | 380V, 50HZ three phase five wire |

Machine Capacity | 230KW (Excluding glue machine and air compressor) |

Bleed pressure | 0.6-0.8Mpa (Air compressor needs to be prepared by customers) |

| Machine weight | 100 Tons approximately |

Quanzhou Womeng Intelligent Equipment Co., Ltd. is located in

Quanzhou, the cultural capital of East Asia and the starting point

of the Maritime Silk Road. Founded in 2016, it is an enterprise

focusing on the R&D, manufacturing and sales of paper

equipment. The products cover sanitary napkin equipment, diaper

equipment, pant equipment, mattress equipment, pad equipment, etc.

The company has excellent products, professional sales and

technical teams, complete supporting facilities, and according to

different market product specifications, each equipment is

customized according to the actual needs of users, and has rich

experience and technical capacity in the design and production of

equipment.

Adhering to the business philosophy of honesty, cooperation and

win-win, the company wholeheartedly provides high-quality products

and services for new and old customers to meet the needs of

customers to the greatest extent. Serving customers and achieving

customers, "pioneering and innovating, pursuing excellence" is the

constant pursuit of Womeng Equipment. We sincerely look forward to

cooperating with new and old customers to create the future!

Whatsapp: +008615805080212

https://www.diapersmachines.com

Adapt to market changes

Market trend response: Pay close attention to market dynamics, once there are new consumer trends, such as the demand for smart care pads, the production line can quickly adjust, develop related products to meet market demand.

Order flexibility processing: With the flexibility to handle different order volumes, whether it is a small batch of customized orders, or large-scale regular orders, can reasonably arrange production to ensure timely delivery.

IF you want to know anything else,please contact us!

|