| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Underpad Making Machine |

|---|---|

| Brand Name: | Womeng |

| Model Number: | WM-FUD16 |

| Certification: | CE |

| Place of Origin: | Fujian,China |

| MOQ: | 1 |

| Price: | $300,000.00-$550,000.00 |

| Payment Terms: | L/C,D/A,D/P,T/T |

| Supply Ability: | 24sets/year |

| Delivery Time: | 90-120days |

| Packaging Details: | Seaworthy Wooden Box |

| Conditon: | New |

| Machinery Test Report: | Provided |

| Packaging System: | Auto Stacker (Customized Design) |

| Working Speed: | 250 meters/min |

| Waste Disposal System: | Automatic waste disposal system |

| Control System: | PLC control system |

| Automatic Grade: | Full automatic |

| Color: | Can be customized |

| Company Info. |

| Quanzhou Womeng Intelligent Equipment Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Production Description

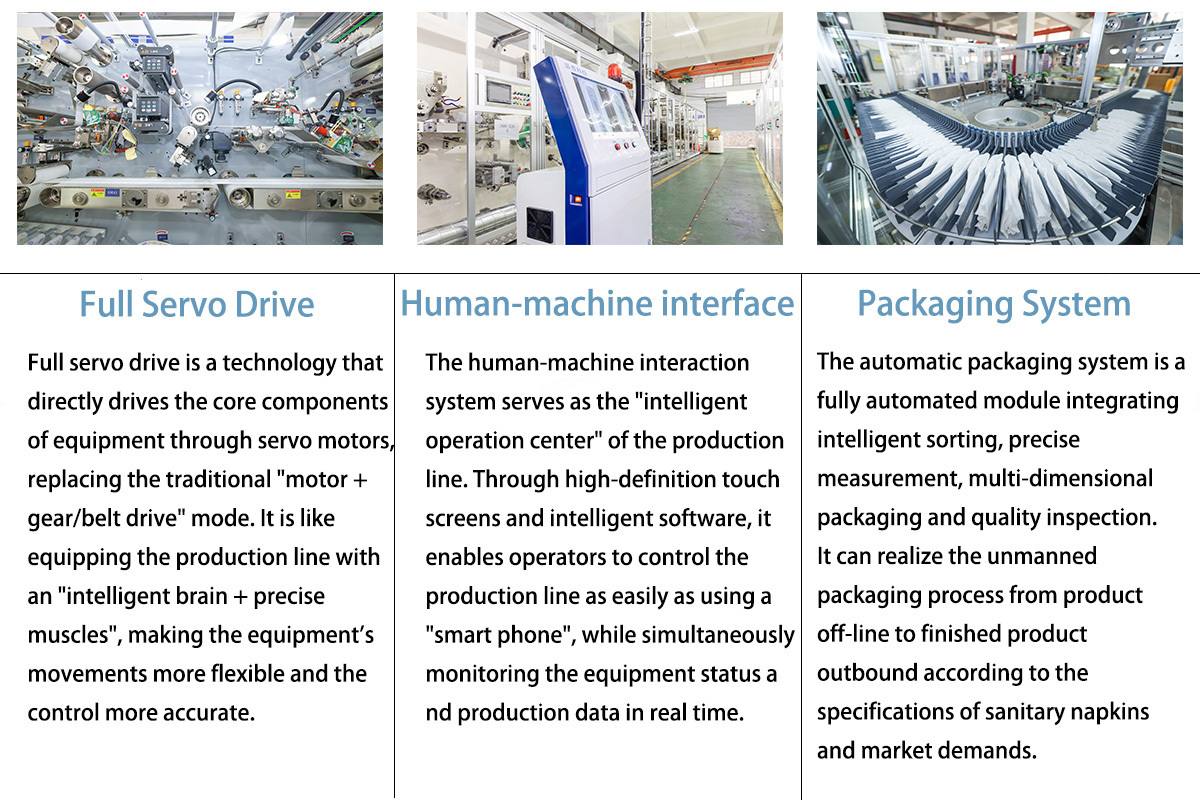

The production line is composed of advanced equipment to achieve efficient operation. The raw materials are quickly transported to the composite process through a precise feeding system, where the hot melt composite equipment is precisely controlled by temperature and pressure, and the fitting is tight and efficient, which is 30% faster than the traditional process. The molding equipment can accurately produce different specifications of nursing pads through intelligent regulation. The automatic equipment in the packaging area completes sorting, bagging and sealing in one go to ensure the efficient and stable operation of the production line.

Product Info

Product size | 26m*5m*3m(for reference only) |

Product structure | Product structure: upper & lower tissue, cotton core (mix with SAP), cover sheet hydrophilic non-woven , ADL (Acquisitiondistribution layer) non-woven,leak guard hydrophobic non-woven back sheet,Waist band non-woven,color pattern sticker,elastic waist band, discarding sticker. |

Control system | PLC control system,HMI Operating on the LED touch screen,Configure

HDTV monitor |

Drive system | Servo Drive(Easy to change size), timing belt and flat belt are

import products, and all the key parts, are import bearings. |

Tension system | Top tissue paper,bottom tissue paper,hydrophobic nonwoven(leg

cuff),top nonwoven,ADL,back sheet,elastic nonwoven are adopt

A&B shaft active unwinding by inverter motor. |

Safety system | It has safety device on the operating side, matched with urgent

stop switch.High audio fan uses sound insulation or silencer. |

| Packaging system | according to customer requirements with palletizer machine (double push double exit ) adjustable |

Materials corrective system | Materials corrective system: Adopt international famous brand deviation correction system |

Power | 380V, 50HZ three phase five wire |

Machine Capacity | 400KW (Excluding glue machine and air compressor) |

Bleed pressure | 0.6-0.8Mpa (Air compressor needs to be prepared by customers) |

| Machine weight | 70 Tons approximately |

Quanzhou Womeng Intelligent Equipment Co., Ltd. is located in

Quanzhou, the cultural capital of East Asia and the starting point

of the Maritime Silk Road. Founded in 2016, it is an enterprise

focusing on the R&D, manufacturing and sales of paper

equipment. The products cover sanitary napkin equipment, diaper

equipment, pant equipment, mattress equipment, pad equipment, etc.

The company has excellent products, professional sales and

technical teams, complete supporting facilities, and according to

different market product specifications, each equipment is

customized according to the actual needs of users, and has rich

experience and technical capacity in the design and production of

equipment.

Adhering to the business philosophy of honesty, cooperation and

win-win, the company wholeheartedly provides high-quality products

and services for new and old customers to meet the needs of

customers to the greatest extent. Serving customers and achieving

customers, "pioneering and innovating, pursuing excellence" is the

constant pursuit of Womeng Equipment. We sincerely look forward to

cooperating with new and old customers to create the future!

Whatsapp: +008615805080212

https://www.diapersmachines.com

The ability to respond to emergencies

Emergency production adjustment mechanism: In the face of emergency situations such as public health emergencies and natural disasters, the demand for health products such as nursing pads may increase dramatically. The care mat production line has a rapid emergency production adjustment ability, enterprises can adjust the production plan in a short time, increase the running time of the production line, and improve the production efficiency of the equipment. At the same time, through close cooperation with raw material suppliers, to ensure the stable supply of raw materials, rapidly increase production capacity, to meet the market in emergency situations for the large demand for care pads, show the social responsibility of the company, but also for the company to win the market reputation.

Equipment failure emergency response plan: The production line has developed a complete equipment failure emergency response plan. For possible equipment failure, stock key parts and maintenance tools in advance, and establish a professional emergency maintenance team. Once the equipment fails, the maintenance team is able to respond quickly, quickly diagnose the cause of the failure and repair it according to the processes and methods in the emergency plan. At the same time, through the switching of standby equipment and the temporary adjustment of the production process, the impact of equipment failure on production is minimized, the continuous operation of the production line is guaranteed, and the product supply is not interfered.

IF you want to know anything else,please contact us!

|