| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Cans Making Machine |

|---|---|

| Brand Name: | BC-MACHINE |

| Model Number: | BC-Drum-30cpm-Auto |

| Certification: | CE |

| Place of Origin: | CHINA |

| MOQ: | 1 |

| Price: | 800000RMB-1500000RMB |

| Payment Terms: | T/T |

| Delivery Time: | 30-45DAYS |

| Packaging Details: | PALLET/WOODEN CASE/STRETCH FILM. |

| Machine Item: | 10L-18L Drum bucket production line |

| Speed: | 30pcs/min |

| Model Quality: | BYM-1160L CNC Machining |

| Material Applicaiton: | Galvanized/Tinplate |

| More Porduction Line: | Welding, sealing,handing,testing |

| Operation Mode: | Fully automatic |

| Delivery date: | 30days-45days |

| Control System: | PLC |

| Power Supply: | 380V/50Hz |

| Power Consumption: | 15KW |

| Company Info. |

| Foshan BetterCan Intelligent Packaging Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

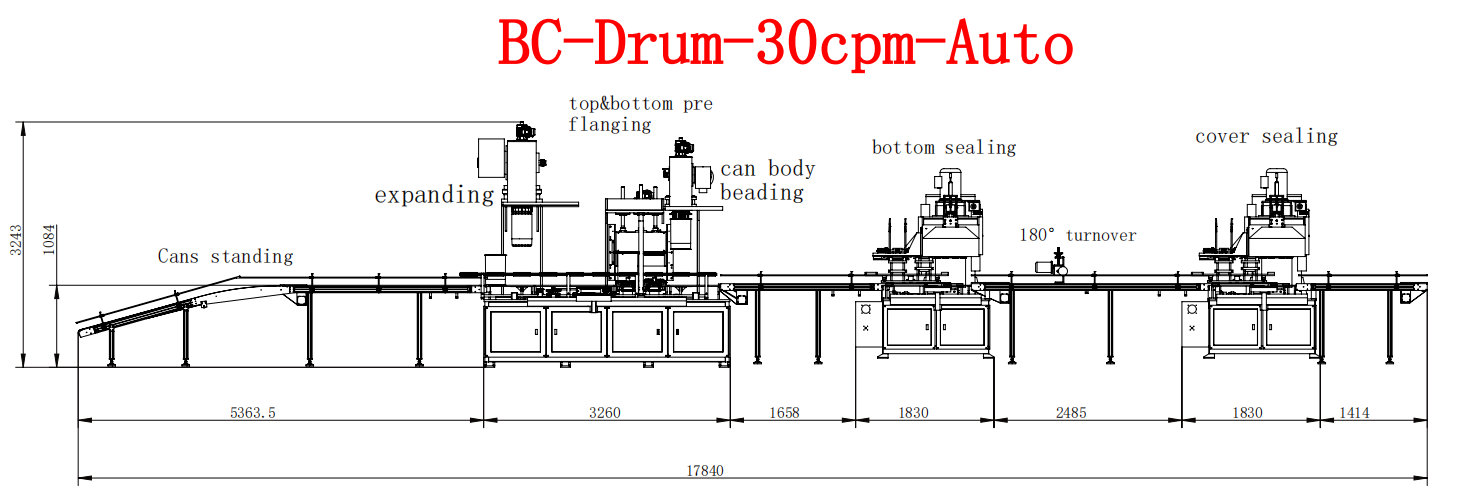

Drum Bucket Making Machine 30cpm Cover Sealed Round Cans Chemical Tin Making Machine

This production line is customized for specific client requirements, featuring expansion, double flanging, and bead rolling processes. Compatible with double/triple-seam drums (5/7 layers).

Process Steps

Stand & Convey – Upright can positioning

Expanding – Initial body expansion

Pre-flanging – Top/bottom preliminary flange forming

Swelling – Precision diameter adjustment

Final Flanging – Top/bottom flange completion

Bottom Seaming – Base sealing

Turn Over – Can inversion

Top Seaming – Final lid sealing

Key Features:

Precision cone expansion technology ensures perfect material distribution

Dual-stage flanging system (secondary press flanging) for superior edge formation

Reinforcement beading capability adds structural rigidity to finished drums

Multi-layer seam compatibility (double & triple-seam configurations)

| Output | 30 CPM |

| Weight of whole line | App.15T |

| Applicable can height | 180-450mm |

| Dimension of whole line | L16000x W1900xH3050(mm) |

| Applicable can diameter | φ220-300mm(need to change moulds) |

| Voltage | Three-phase four-line 380V (Can be configured according to different countries) |

| Air pressure | No less than 0.4MPa |

| Power of whole line | 31kW App.31kW |

| Connection height | 1000±10mm |

Finished Product:

MORE RELATED PRODUCTION LINES | SPEED PER MIN |

18LF full-auto production line for square cans | 35CPM |

High-speed pail production line | 45CPM |

Medium-speed pail production line | 35-37CPM |

Full-auto production line for small rectangular cans | 30CPM |

18LF drum automatic production line | 30CPM |

Integrated small rectangular can production line | 40CPM |

1-5L small round can auto line | 60CPM |

200L barrel production line | 12CPM-15CPM |

Small rectangular can flanging & seaming machine | 40CPM |

Integrated fan-shaped tank production line | 40CPM |

We offer a range of machines ready to upgrade your production line. These can be customized to seamlessly integrate with your existing equipment.

Automatic Deep Throat Press | Loading And Receiving Circular Knife Machine |

Automatic Cutting Machine | Automatic Conveying (Collecting Can) Line |

Automatic Handing Machine | Magnetic Conveying equipment |

Automatic Welding Machine | Magnetic vertical cans equipment |

Automatic Sealing Bottom Machine | Robotic Feeder |

Automatic Leakage Tester | Palletizer |

Automatic Strip Press | Electromagnetic Dryer |

Regarding components;

we can provide quality goods and timely delivery from our own production line.

Solution A:Buy components in our COMPONENTS RANGE,click here.we can offer comprehensive components ranges to support the bottom,top,lid,handle,lug lid etc...

Solutiono B:Purchase press machine,when you has sufficient production capacity,buying a set of press machine could help save money in a long term.

Regarding ensuring the cans maintenance;

Installation: Propose the installation drawings and the supporting equipment and accessories that the customer needs to prepare. we'll send engineers to your factory to guide the installation (travel expenses charged from buyer).

After-sales support: You can set up a work group to deal with problems in a timely manner after sales, or send people every year for technical guidance and communication (this item requires a fee)

Maintenance and supply of parts: Consumable parts can be purchased in advance and shipped together with the equipment. Subsequent purchases can be made by air express or sea.

|