| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Metal Cabinet Assembly |

|---|---|

| Brand Name: | Xianheng |

| Model Number: | Custom Made |

| Certification: | ISO 9001:2015 SGS RoHS |

| Place of Origin: | China Guangdong |

| MOQ: | 1 pcs |

| Price: | USD 0.1$-2$ |

| Payment Terms: | T/T, Western Union, MoneyGram |

| Supply Ability: | 10 SET per week |

| Delivery Time: | 5-8 days |

| Packaging Details: | Carton Wooden case |

| Material Capabilities: | Stainless Steel,Aluminium,Copper,Brass |

| Products: | Metal eauipment shell, Sheet Metal Cabinet Assembly Stamping Parts |

| Process: | Metal casing,Metal sheets fabrication,Welding Cutting Punching Stamping |

| Application: | Carbinet, parts:Cars, e-sports hotel, architecture, furniture,metal plastic parts |

| Tolerance: | +/-0.02mm |

| MOQ: | 1 Piece |

| OEM/ODM: | Acceptable |

| Equipment: | Laser Cutter, CNC Bending Machine, Stamping Machine, Weld |

| Surface treatment:: | Galvanized,Anodizing,Powder Coated,Chrome Plating,Nickel plating etc. |

| Craftsmanship: | CNC stamping,CNC bending,Welding,Laser cutter, Stamping |

| Applications: | Automotive,Medical,Telecom,Construction,machine etc |

| Keyword: | Elctric Metal Eauipment shell, Sheet Metal Cabinet Assembly Stamping Parts |

| Inspection Tool: | Measuring Tape, Caliper, R Gauge, X-Ray, Salt Spray |

| Package: | Platic Bag ,Blister Box ,Tap Reel or as your required |

| Company Info. |

| Shenzhen Xianheng Technology Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

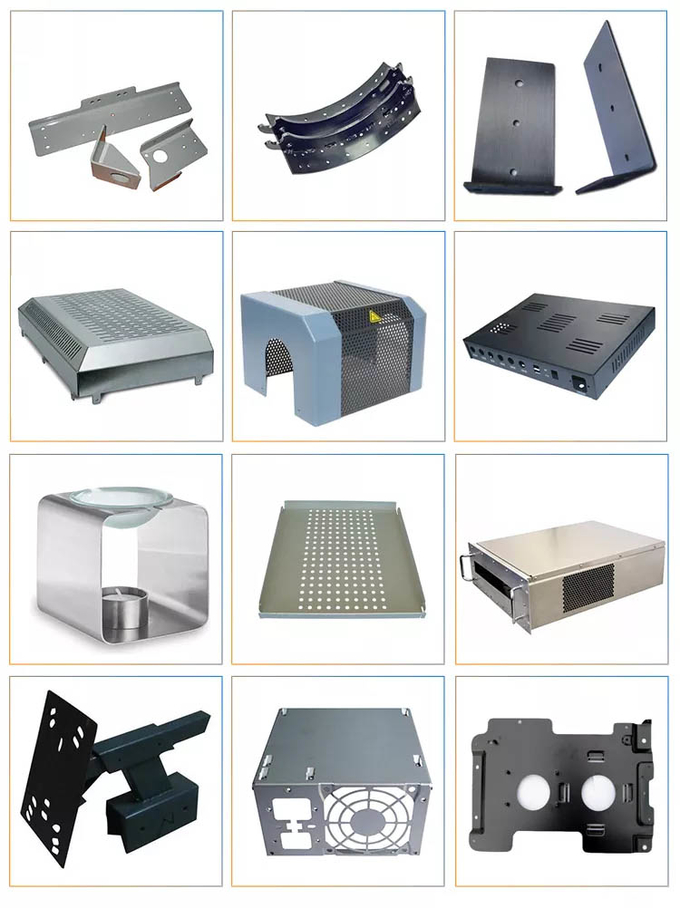

Customized Carbon Steel Stamping Stainless Steel Shell Medical Equipment Metal Cabinet Assembly Manufacturer

Description of Customized Carbon Steel Stamping Stainless Steel Shell Medical Equipment Metal Cabinet Assembly Manufacturer

A Customized Carbon Steel Stamping Stainless Steel Shell Medical Equipment Metal Cabinet Assembly Manufacturer specializes in designing, engineering, and producing high-precision metal cabinets tailored for medical applications. These manufacturers leverage advanced stamping technologies to shape carbon steel components, ensuring structural robustness, while integrating stainless steel shells for corrosion resistance and hygiene. The cabinets are customized to meet specific medical requirements, such as storage for surgical instruments, pharmaceuticals, or diagnostic equipment, and adhere to stringent industry standards. The manufacturer’s expertise spans prototyping, mass production, and quality assurance, offering solutions that balance durability, functionality, and aesthetic appeal for healthcare environments.

Specification of Customized Carbon Steel Stamping Stainless Steel Shell Medical Equipment Metal Cabinet Assembly Manufacturer

| CNC Capacity | ||||

| CNC Machining Center | 3 / 4 / 5 axis CNC Machining Centers | 40+ CNC Machines | ||

| CNC Turning | φ0.5 - φ300 * 750 mm | DIN-2768-Fine +/-0.005 mm | ||

| CNC Machining | 1270×508×635 mm(max) | DIN-2768-Fine +/-0.005 mm | ||

| CNC Stamping | 1000 * 1000 mm(max) | DIN-2768-Fine +/-0.005 mm | ||

| Drawing Format | IGS,STP,X_T ,DXF,DWG , Pro/E, PDF | |||

| Inspection Equipments | Measurement Instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. | |||

| Material Available | ||||

| Stainless Steel | SS201,SS301, SS303, SS304, SS316, SS416, 17-4PH, etc. | |||

| Steel | Mild steel, Carbon Steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. | |||

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. | |||

| Copper | C11000,C12000,C12000 C36000 etc. | |||

| Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. | |||

| Iron | A36, 45#, 1213, 12L14, 1215 etc. | |||

| Plastic | ABS, PC, PE, POM, Delrin, Nylon, Teflon, PP,PEI, Peek etc. | |||

| Surface Finishing | ||||

| Aluminum Parts | Stainless Steel Parts | Steel Parts | Copper /Brass | Plastic Parts |

| Clear Anodized | Polishing | Zinc plating | Polishing | Painting |

| Color Anodized | Passivating | Oxide black | Passivation | Chrome plating |

| Sandblast Anodized | Sandblasting | Nickel plating | Galvanized | polishing |

| Chemical Film | Laser engraving | Chrome plating | Nickel Plating | Sandblast |

| Brushing | Carburized | Chrome plating | Laser engraving | |

| Polishing | Heat treatment | |||

| Chroming | Powder Coated | |||

Application Of Customized Carbon Steel Stamping Stainless Steel Shell Medical Equipment Metal Cabinet Assembly Manufacturer

1. Auto Components Hardware Parts Auto Parts

2. Communication Equipment

3. Industrial Equipment

4. Medical EquipmentsMechanical Parts

5. Ship Accessories

6. Electrical Equipment

7. Mechanical Equipment

Feature Of Customized Carbon Steel Stamping Stainless Steel Shell Medical Equipment Metal Cabinet Assembly Manufacturer

1. Good corrosion resistance

2. High strength and hardness

3. High thermal conductivity

4. Good finishing characteristics

Advantages

1. Specialized Expertise in Medical Compliance:

Manufacturers specializing in medical-grade cabinets deeply

understand regulatory requirements (e.g., cleanroom standards,

sterilization compatibility) and design products that inherently

meet or exceed these criteria. This reduces compliance risks for

healthcare facilities and ensures seamless integration into

clinical workflows.

2. Tailored Solutions for Diverse Medical Needs:

By offering customization options—such as modular layouts,

adjustable shelving, or integrated security features—these

manufacturers enable healthcare providers to optimize storage

solutions for specific equipment or supplies. This flexibility

enhances operational efficiency and supports patient safety by

organizing tools and materials in ergonomic, accessible ways.

3. Advanced Materials and Long-Term Reliability:

The use of carbon steel for structural integrity and stainless

steel for exterior surfaces ensures cabinets withstand harsh

medical environments, including frequent cleaning, chemical

exposure, and heavy use. This durability minimizes downtime,

reduces replacement costs, and provides a sustainable investment

for healthcare infrastructure.

FAQ

Q1: Where can I get product & price information?

A1:Send us inquiry e-mail, we will contact you as we receive your

mail.

Q2: How long can I get the sample?

A2:Depends on your specific items, within 3-7 days is required

generally.

Q3: What kinds of information you need for quote?

A3:Kindly please provide the product drawing in PDF, and will be

better you can provide in STEP or IGS.

Q4: What are the payment terms?

A4: We accept 50% as payment deposit, when the goods is done, we

take photos for your check and you then pay the balance.

Q5: Are you a trading company or factory?

A5:We are direct factory with 10 experienced engineers and more

than 650 employees as well approximate 2,000 square ft. workshop

area.

Q6: What shall we do if we do not have drawings?

A6:Please send your sample to our factory, then we can copy or

provide you better solutions. Please send us pictures or drafts

with dimensions (Length, Hight, Width), CAD or 3D file will be made

for you if placed order.

|