| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Brushed Motor DC |

|---|---|

| Brand Name: | Lihua Motor/HCS Motors |

| Model Number: | RK-3030SA-18320 |

| Certification: | ISO9001 Reach,RoHs,SGS,CE |

| Place of Origin: | Dongguan China |

| MOQ: | 3000PCS |

| Price: | Negotiation |

| Payment Terms: | ,L/C,T/T,D/P,D/A,Western Union,MoneyGram |

| Supply Ability: | 10000PCS/Day |

| Delivery Time: | 40-45days |

| Packaging Details: | Plastic/Foam Box |

| Motor Type: | RK-3030SA-18320 |

| Direction of Rotation: | CCW/CW |

| Output Shaft Diameter: | 2.3mm |

| Shaft Length: | Free Custom |

| Body Size: | 33mm*30mm(Not including Shaft length) |

| Motor Volt: | 3V/5V/6V/7.8V/12V/13.5V |

| No-load Speed: | 2900RPM/5000RPM/5100RPM/5600RPM/5800RPM |

| Application: | Pump/Intelligent bathroom |

| Company Info. |

| Guang Dong Lihua Mechatronics Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Small Electric Motors 12V RK-3030SA 30mm For Air Pump High Torque Mini Motor

Model: RK-3030SA-18320

Volt:12.0V

Current:≤65mA

No-Load Speed:4600±230r/min

Output shaft: 2.3MM

Shaft length: 8.0±0.15mm

Screw hole: 2.6*0.45MM

Weight: 38 g

Height:30.5MM (excluding front and rear bearing housings)

Motor outer diameter:30 mm

Application:ATM/ Automatic vending machine/Copy machine/Paper money counter/Pump.

Model: RK-3030SA-20260B

Volt:12.0V

Current:≤100mA

No-Load Speed:5600±280r/min

Output shaft: 2.3MM

Shaft length: 8.0±0.15mm

Screw hole: 2.6*0.45MM

Model: RK-3030SA-13385

Volt:13.5V

Current:≤75mA

No-Load Speed:4150±332r/min

Output shaft: 2.3MM

Shaft length: 8.1±0.2mm

Screw hole: 2.6*0.45MM

Introduction: Permanent magnet brushed DC motor is equipped with permanent magnets that provide a strong magnetic field and ensure efficient operation. The brushed design of the motor allows for easy maintenance and adjustment of speed and torque.

Product Note: Data in this typical specification sheet are for other certain customers. Voltage, rated torque, speed, current, power and shaft extension feature & dimension can be customized to meet customer specific requirement.

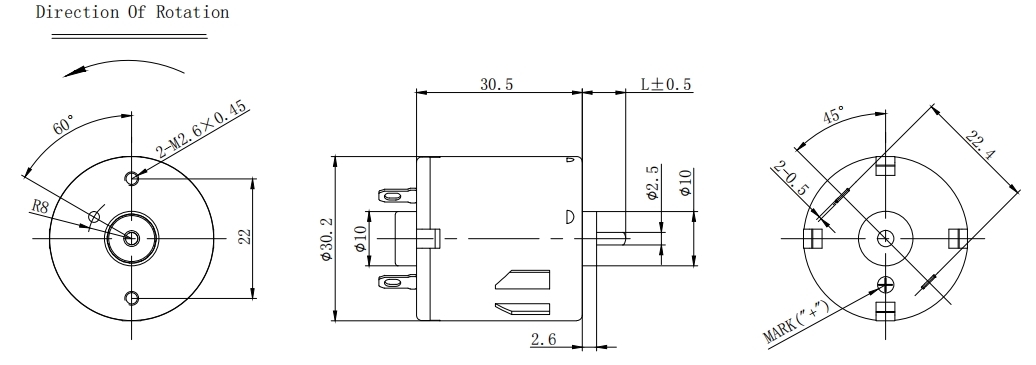

RK-3030SA 30mm Mini Carbon Brushed Motor Dimension

RK-3030SA 30mm Diameter Motor Size:

Direction of Rotation:CCW/CW

Screw Hole Size:2.6*0.45mm

Screw Hole Distance:22mm

Motor Shell Height:30.5mm

Motor Shell Diameter:30.2mm

Front /End Cover Diameter:10mm

Front Step Height:2.6mm

Motor Shaft Diameter:2.5mm

Terminal Distance:22.4mm

Motor Shaft Length:L±0.5mm

FAQ

Micro DC Motors in Water Pump Applications: Advantages & Working Principles

Micro DC motors provide diverse power outputs (suction, vibration, extension, oscillation, etc.) for various applications. Below is a concise explanation of their advantages and working principles in water pumps.

A DC motor pump generates suction via high-speed rotation. During operation:

The coil and commutator rotate continuously

The magnets and carbon brushes remain stationary

Current direction alternates through brush-commutator contact

✅ Pros:

Low cost

Easy speed control

High starting torque

❌ Cons:

Brush-commutator friction increases noise

Limited lifespan (~1000 hours)

✅ Pros:

No brush/commutator wear (uses electronic commutation)

Longer lifespan (depends on bearings)

Lower noise

❌ Cons:

Complex speed control

1–3x higher cost than brushed motors

Compact, efficient, low-maintenance with extended lifespan

Customizable specs under the same voltage (e.g., 12V 20,000 RPM or 12V 25,000 RPM)

High precision & low noise (<35 dB; near-silent for low-power models)

Flexible speed control via PWM, analog signals, or potentiometers

⚠ Avoid:

Particle ingress (metallic debris increases friction)

Demagnetization (caused by overheating)

Prolonged idling

Electrical specs: Higher voltage = faster speed but more noise/current

Size/shape constraints

Operating environment (e.g., temperature limits)

|