| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Industrial Steel Building |

|---|---|

| Brand Name: | Lanjing |

| Model Number: | LJ-S02 |

| Certification: | CE, ISO, SGS |

| Place of Origin: | Weifang,China |

| MOQ: | 200 square meters |

| Price: | UD$20-80 per square meter |

| Payment Terms: | L/C,T/T,D/P |

| Supply Ability: | 2500 tons per month |

| Delivery Time: | 30-40 working days |

| Packaging Details: | steel pallet / Bulk |

| Standard: | GB |

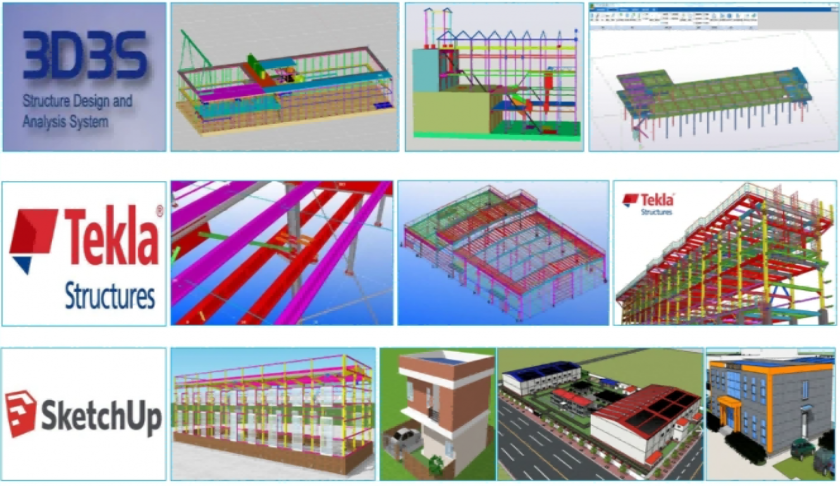

| Software: | CAD, Tekla, Sketchup, Pkpm, Bim |

| Project Solution Capability: | Graphic Design, 3D Model Design |

| Packing & Delivery: | Load Into 20gp, 40gp/ 40hq Containers |

| Design Load: | Wind, Snow, Seismic |

| After Sale Service: | Installation Drawing,Installation Video |

| Company Info. |

| Shandong Lanjing Building & Construction Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Material Quality Assurance Industrial Steel Building Fire Resistant Steel Quick Assembly

China Premier Steel Structure Building Manufacture for the Global Market

With a solid foundation in the Chinese domestic market, we are now expanding our reach to bring our high-quality steel structure factory buildings to the world.

Our products are a combination of traditional Chinese craftsmanship and modern technological innovation, designed to meet the diverse needs of international customers.

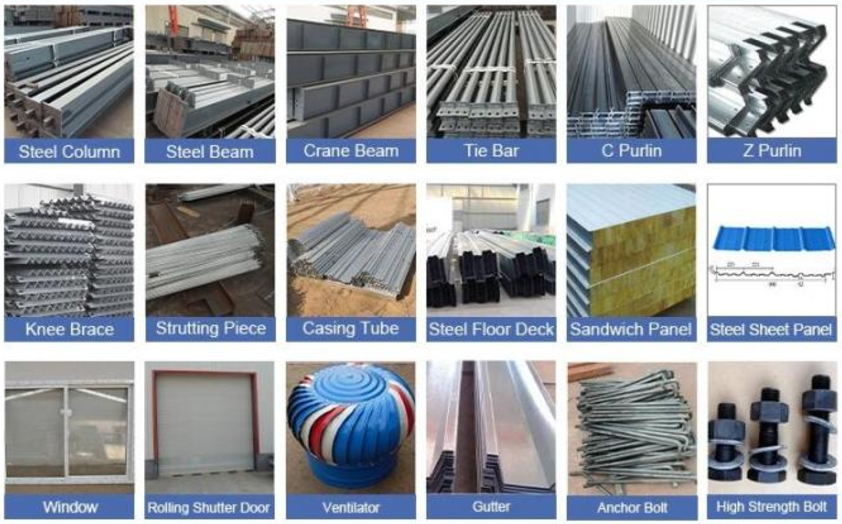

Prefabricated steel structure building has features of high fire resistance and strong corrosion resistance. Steel structure warehouse is mainly refers to the main bearing component is composed of steel. Including the steel columns, steel beams, steel structure, and steel roof truss. Each component uses welds, bolts, or rivets to connect.

The roof and wall can be made of composite panels or veneer. Galvanized sheet metal can prevent rust and corrosion. The use of a self-tapping screw can make the connection between the plates more closely, to prevent leakage. You can also use composite panels for roofs and wall. The sandwich is polystyrene, glass fiber, rock wool, and polyurethane. They have good thermal insulation, heat insulation, and fire-retardant. The wall of the steel structure maintenance also can use brick wall. The cost of a brick wall is higher than a galvanized steel roof and wall.

| Items | Specification | |

| Main Steel Frame | Column | Q235, Q355 Welded H Section Steel |

| Beam | Q235, Q355 Welded H Section Steel | |

| Secondary Frame | Purlin | Q235 C and Z purlin |

| Knee brace | Q235 Angle Steel | |

| Tie Rod | Q235 Circular Steel Pipe | |

| Brace | Q235 Round Bar | |

| Vertical and Horizontal Support | Q235 Angle Steel, Round Bar or Steel Pipe | |

| Maintenance system | Roof Panel | EPS Sandwich Panel /Glass Fiber Sandwich Panel |

| Rock Wool Sandwich Panel / Pu Sandwich Panel /Steel Sheet | ||

| Wall Panel | Sandwich Panel / Corrugated Steel Sheet | |

| Accessories | Window | Aluminium Alloy Window / PVC Window / Sandwich Panel Window |

| Door | Sliding Sandwich Panel Door / Rolling Metal Door / Personal Door | |

| Downspout | PVC | |

| Live load on Roof | In 120kg/Sqm (Color steel panel surrounded) | |

| Wind Resistance Grade | 12 Grades | |

| Earthquake-resistance | 8 Grades | |

| Structure Usage | Up to 50 years | |

| Temperature | Suitable temperature.-50ºC~+50ºC | |

| Certification | CE, SGS, ISO9001:2008, ISO14001:2004 | |

| Finishing Options | Vast array of colors and textures available | |

| Paint Options | Alkyd painting, two primary painting, two finish painting | |

| Gray paint, red paint, white paint, epoxy zinc etc. Or Galvanized. | ||

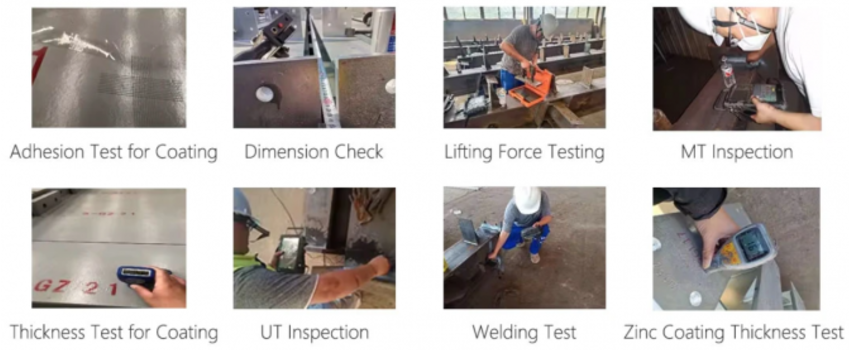

At our steel structure factory, “Safety First” isn't just a slogan; it's the guiding principle for every project. We're committed to upholding the highest standards of labor safety. Our senior supervisors closely monitor all safety and quality - related technical criteria, ensuring that each project meets the original safety pledges.

Each construction stage is subject to comprehensive safety audits. Any deviation from safety norms is promptly rectified. Our steel structures not only surpass industry - leading safety standards but also provide long - term security for all end - users.

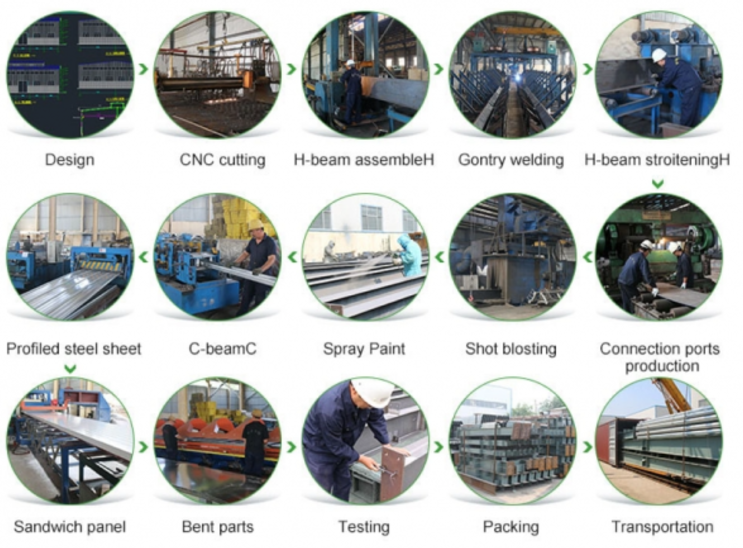

Our steel structure factory is dedicated to continuous innovation. By leveraging advanced machinery, along with state - of - the - art design and manufacturing technologies, we’re always exploring new solutions to refine our products. These technological investments have optimized our production lines, enabling us to achieve maximum productivity. We consistently produce high - quality steel structures that meet the most demanding industry standards.

Looking ahead, we aim to incorporate revolutionary technologies such as AI - powered manufacturing processes. This strategic move will not only enhance our production capacity but also elevate the overall quality of our offerings, solidifying our position as an industry leader.

Our steel structure factory offers an all - inclusive service package. From the initial consultancy and design phases, through production, construction, and project completion, we are actively involved at every step. To ensure cost - effectiveness, we tailor our pricing to each client’s unique needs, taking into account project specifications and market conditions.

Our seasoned cost - management team continuously monitors market trends. By analyzing data on material costs, labor expenses, and industry developments, we are able to offer highly competitive prices. This ensures that clients get the most out of their investment, receiving top - tier services at the best possible price.

Wide Range of Applications

Our Steel Structure Workshop Warehouse is perfect for various applications, including manufacturing plants, automotive repair shops, and woodworking workshops, among others. The versatility and durability of our steel structure workshop Warehouse make it ideal for various industries and businesses.

In summary, our Steel Structure Workshop Warehouse is a reliable and customized solution for your building facilities and construction materials needs. With our galvanized steel structure, custom steel fabrication capabilities, and various door and roof cladding options, we can create a workshop warehouse that meets your unique requirements and preferences.

We take pride in our custom steel fabrication capabilities, which means that we can create a Steel Structure Warehouse Workshop that suits your business requirements. Whether you need a large workshop for industrial purposes or a smaller one for personal use, we can design and build it for you.

Our Steel Structure Workshop Warehouse product comes with comprehensive technical support and services to ensure a smooth and successful installation process.

Our team of experts is available to provide guidance and assistance at every stage of the project, from design to construction. We offer detailed product specifications, CAD drawings, and engineering calculations to help you make informed decisions and ensure compliance with industry standards.

In addition, we provide on-site installation supervision and training to ensure that the installation is carried out to the highest standards of safety and quality. Our goal is to ensure that you have a reliable and durable workshop that meets your specific needs and requirements.

| service | Quality inspection | Factory Self-inspection by QC Customer inspection Third party inspection |

| Design and Drawing | Construction blueprint design Steel structure detailed drawing 3D model by auto cad / ifc Install detailed drawing | |

| Manufacture | Manufacture various steel components based on different conditions of projects, steel plates, sectional profiles, metal sheets, flashing, ventialtor and other building accessories to guarantee the whole construction project | |

| Installation | Install detailed drawings to guide On-line / remote guidance for installation. Engineer to guide on site or The installing team to process all

installation on site. |

A. If you have the drawing of your project:

We could check your drawing details and quoted accordingly. After all details are confirmed. The rest full service of production, shipment and installation guide will be offered.

B. No drawing:

Our designer team will make drawings for your check with free technical support. Firstly we need to confirm your project details as belows. If you help to confirm in advance, we could process for you quickly and directly.

1. Dimension:Length × width × height .

2. Doors and Windows: Dimension, quantity, position.

3. Local wind load, snow load, roof load...

4. Roof and wall materials:Insulated Sandwich panel or metal sheet,

birck wall's height

5. Crane and tons?

6. Building usage could also help us to choose the right materials

and plans for you.

7. Other requirements:such as anti-corrosion requirements, parapet,

messanine, partitions, decorative materials or others

|