| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Reinforced PP |

|---|---|

| Flame Retardancy: | UL94 Rating V0-V2 |

| Tensile strength: | 35MPa |

| Usage: | General Plastics, Engineering Plastics, Specialty Plastics |

| Melt Flow Rate: | 20g/10min |

| Molding Method: | Injection Molding |

| Transmittance of the 1mm tablet: | 64%-81% |

| Shape: | Granules |

| Functionality: | High Impact Resistance, High Transparency, High Temperature Resistance, High Haze, Weather Resistance, High Flowability |

| Material: | Polypropylene/PP |

| Place of Origin: | China |

| Brand Name: | HMT |

| Certification: | ISO 9001, ISO 14001, RoHS/REACH |

| Price: | Negotiable |

| Packaging Details: | Export Film Packing / According To Customer |

| Delivery Time: | 7-15 working days |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram |

| Company Info. |

| Xiamen HMT International Trade Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Injection-Molding Optimized Recycled PP – Glass Fiber Reinforced Modified Material

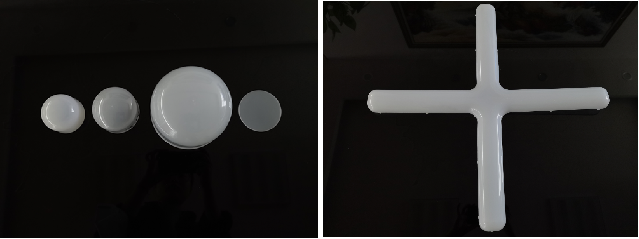

Product models in the automotive lighting field

| Number | Project | Unit | H40S | Test value | Test Methods | |

| 1 | Melt mass-flow rate(MFR) | Nominal value | g/10min | 37 | 37.3 | GB/T 3862 |

| ±37 | Deviation | |||||

| 2 | Isotactic index | % | >=96.0 | 97.51 | GB/T 2412 | |

| 3 | Particle appearance | Color grain | Pc/kg | <=5 | 0 | SH/T 1541-2006 |

| Black grain | Pc/kg | 0 | 0 | |||

| Large and small grains | g/kg | <=100 | 0.1 | |||

| Snake skin grains and trailing grains | Pc/kg | report | 25 | |||

| 4 | Impurities and others | Pc/kg | no | no | SH/T 1541-2006 | |

| 5 | Ash | % | <=0.030 | 0.014 | GB/T 9345.1 | |

| 6 | Tensile properties | Tensile modulus of elasticity(Et) | MPa | >=1200 | 1250 | GB/T 1040 |

| Tensile yield stress(σ y) | MPa | >=30.0 | 30.9 | |||

| Tensile stress atbreak(σ B) | MPa | >=8.0 | 20.7 | |||

| Nominal tensile strain at break(ε tB) | % | >=200 | 566 | |||

| Test conclusion | Qualified | |||||

Production Description

Polypropylene resin combines hydrocarbon resistance with autoclave sterilizability (up to 121°C). The material's crystallinity (40-60%) and tacticity (isotactic configuration) determine optical clarity and barrier properties. Common additives include nucleating agents, antistatics, and flame retardants for specialized grades.

Key Advantages Over Standard PP

Tailored performance for niche applications.

Cost-effective alternative to engineering plastics like ABS or nylon.

Retains PP’s inherent benefits (lightweight, chemical resistance) while addressing weaknesses.

Product application in LED light field

Product application in Switch and Socket

Product application in Toilet-Seat

Company Profile

HMT International is a leading global manufacturer and exporter specializing in modified plastics, operating under the brand Chongyuan. Established with a commitment to innovation and sustainability, we engineer high-performance thermoplastic compounds tailored to meet the evolving demands of industries worldwide.

Certified to ISO 9001, ISO 14001, and compliant with RoHS/REACH standards, we align our operations with global sustainability goals while delivering exceptional technical support and supply chain reliability.

3,000+ customized formulations.

500,000+ MT annual production capacity.

25+ years of polymer expertise.

ISO 9001 & ISO 14001 certified facilities.

|