| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Steel Structure Shed |

|---|---|

| Brand Name: | YDX |

| Model Number: | YDX-Y8 |

| Certification: | CE ISO SGS |

| Place of Origin: | CHINA,QINGDAO |

| MOQ: | 1-10000 square meters |

| Price: | $35.00-$63.00 |

| Payment Terms: | T/T |

| Supply Ability: | 10000 tons/month |

| Delivery Time: | 20-30 works days |

| Packaging Details: | Exported standard packing |

| Structure: | Steel Structure Frame Welded |

| Purlin Surface: | Galvanized |

| Size: | Customized |

| Color: | Galvanized/Customized |

| Connection: | All Bolt Connection |

| Feature: | Anti Corrosion |

| Material: | Steel |

| Roof And Wall: | pu,eps,rock wool Sandwich Panel |

| Company Info. |

| Qingdao Yidongxiang Steel Structure Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

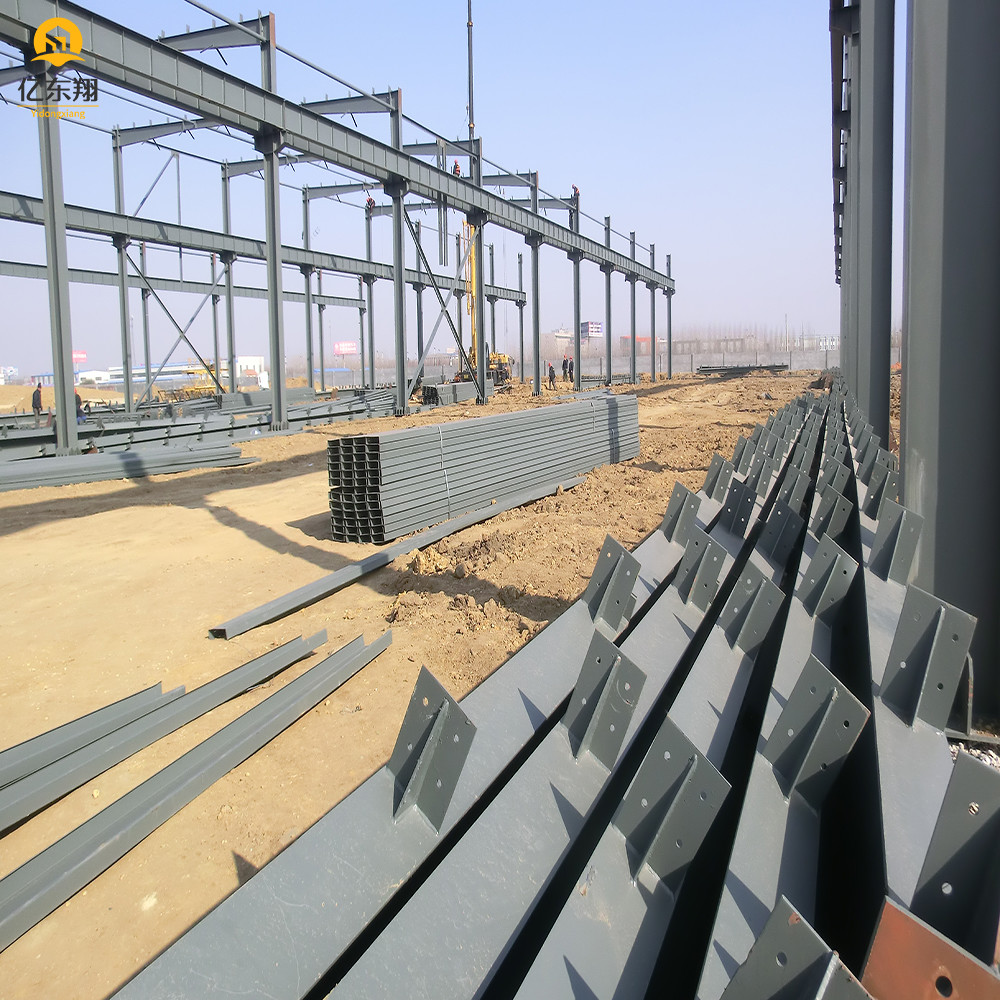

Steel structure sheds are pre-engineered, modular buildings designed for versatile applications, including storage, industrial workspaces, agricultural shelters, and commercial facilities. Constructed from high-strength steel components fabricated off-site, these sheds are quick to assemble, cost-effective, and durable. They are ideal for projects requiring rapid deployment and adaptability to harsh environments.

Key Design Elements

| Aspect | Description | Tools/Standards |

|---|---|---|

| Load Analysis | Calculates dead, live, wind, and seismic loads (e.g., ASCE 7-22 standards). | SAP2000, ETABS |

| Modular Layout | Customizable spans (10–50m+) and heights to suit functional needs. | AutoCAD, Revit |

| Ventilation & Lighting | Integrated skylights, louvers, or ridge vents for airflow and natural light. | BIM software for energy modeling |

| Drainage Systems | Sloped roofs (5–10° pitch) and gutter systems to prevent water accumulation. | Civil 3D for hydrological analysis |

Design Process Workflow

| Feature | Advantage | Example/Case |

|---|---|---|

| Rapid Assembly | Erected in days vs. months for traditional builds. | 1,000㎡ warehouse built in 7 days. |

| Low Maintenance | Corrosion-resistant coatings (e.g., galvanization) reduce upkeep costs. | Agricultural sheds in coastal regions. |

| Scalability | Easy expansion by adding modular sections. | Logistics hubs scaling with business growth. |

| Weather Resistance | Withstands heavy snow (up to 1.5kN/㎡), winds (150km/h+), and UV exposure. | Mountain equipment shelters. |

| Eco-Friendly | 100% recyclable steel; reduced carbon footprint. | LEED-certified industrial sheds. |

Primary Materials

| Component | Material Type | Specifications |

|---|---|---|

| Main Frame | Hot-rolled steel (ASTM A36/A572) | Beams (H-shaped, I-shaped), columns, purlins. |

| Cladding | Galvanized steel, aluminum | Corrugated sheets or sandwich panels (EPS/PU core). |

| Fasteners | Grade 8.8 bolts, self-drilling screws | ISO 4017 standards for tensile strength. |

| Foundation | Reinforced concrete footings | Depth adjusted for soil bearing capacity. |

| Protective Coatings | Epoxy primer + PVDF topcoat | 20+ years lifespan in corrosive environments. |

Installation Steps

| Stage | Procedure | Equipment |

|---|---|---|

| Site Preparation | Leveling ground, marking anchor bolt positions. | Excavators, laser levels |

| Foundation Pouring | Casting concrete footings with embedded bolts. | Concrete mixers, vibrators |

| Frame Erection | Assembling columns and beams using cranes. | Mobile cranes, torque wrenches |

| Cladding Installation | Fixing panels/roofing sheets with screws. | Scissor lifts, screw guns |

| Final Inspection | Checking alignment, bolt tightness, and safety. | Ultrasonic testers, torque testers |

| Industry | Use Case | Example Projects |

|---|---|---|

| Industrial | Machinery storage, workshops | Automotive parts warehouses, CNC machine sheds |

| Agricultural | Livestock barns, grain storage | Dairy cow shelters, hay storage units |

| Commercial | Parking sheds, retail kiosks | Supermarket outdoor storage, car dealerships |

| Public Infrastructure | Bus terminals, sports complexes | Covered stadium bleachers, emergency shelters |

| Renewable Energy | Solar panel mounting structures | Solar carports, wind turbine maintenance sheds |

Steel structure sheds epitomize modern engineering efficiency, blending durability with adaptability to meet diverse global needs.

| Steel structure building | ||||

| 1. Primary Framing | Box beam column, cross steel column, H-shaped steel column, steel beam | |||

| 2. Secondary Framing | Galvanized Z and C sections purlin | |||

| 3. Roof and Wall panels | Steel sheet and insulated sandwich panels (EPS, fiberglass wool and PU). | |||

| 4. Steel Decking Floor | Galvanized steel decking board | |||

| 5.Structural subsystem | Divider, gutter, awning, partition wall | |||

| 6.Mezzanines, Platforms | Painted or galvanized H beam | |||

| 7.Other Building Accessories | Sliding doors, roll up doors, aluminium windows, louvers, etc. | |||

| Service Life | 50-70years | support | steel angle, steel pipe, steel round | |

| Place of Origin | Qingdao,Shandong,China | Application | workshop, warehouse, poultry house,garage etc | |

| Grade | Q235B, Q355B or as per customer's need | Bolt Grade | M20, M16, M14 etc | |

| Connection | intensive bolt, ordinary bolt | Window | PVC steel or aluminum alloy | |

| Downspout | PVC pipe or as per customer's request | Door | sliding or rolling door | |

| Purlin | C/Z shape profile | Panel | EPS/PU/fiber glass/rock wool | |

| Main Frame | Welded or hot rolled H-shaped steel, columns, beams, box beams and columns | |||

| Drawings & Quotation: | ||||

| (1) Customized design is welcomed. | ||||

| (2) In order to promise an accurate quotation and drawings, please let us know the length, width, eave height and local weather.We will quote for you promptly. | ||||

Our Service

I. We would offer you the proposed design plan and the most valuable quotation based on the parameter of the following information.

1. Building Dimension: Length*width*height, eave height, roof type

etc.

2. Doors and windows: Dimension, quantity, position to put them if

you have your own requirements.

3. Local climate: Wind speed, snow load, earthquake etc.

4. Insulation material for roof and wall: Sandwich panel or single

metal sheet.

5. Crane if have: Do you need crane beam inside the steel

structure? And its capacity.

6. If have other requirements, such as fire proofing, isolated roof

,roof ventilation and daylighting etc, please kindly inform us.

II. In accordance with your requirement, our experienced engineers

would provide the best program.

III. We would give the best service to our client, including

design, manufacturing,installation and after-sale service etc.

We can provide the service of installation, supervision, and training by extra. We will dispatch our engineers team to your country to guide the assemble work, and we will provide the detailed professional installation drawings and guide installation service team keep 24-hour online service ,they will help you to install your steel structure building .

IV. QC processing:

1. Every one week meeting for Quality Audit to solve the weakness during processing and procedures

2. Every two weeks meeting for employee training.

3. Producing as to the International Steel Structure Standard with ISO 9001 Quality Control System

4. Each project, every 1 months, connect with clients for feedback and complaints, then improve the quality control actions.

5. Quality inspection report for every process during production. Ensure 100% good quality products.

FAQ

I. What kind of Industry Steel Workshop do you need?

There are very experienced, expertised engineers in our company who can design whatever shape of buildings as your request. Your building is a major investment and you take it seriously. So do we! .

We are professional manufacturer of steel structure building.

III:Do you offer guiding installation on site overseas for warehouse building?

Yes, we can provide the service of installation, supervision, and training by extra. We will dispatch our engineers team to your country to guide the assemble work, and we will provide the detailed professional installation drawings and guide installation service team keep 24-hour online service ,they will help you to install your steel structure building .

IV. What's the quality assurance you provided and how do you

control quality?

We have professional QC team monitoring the quality at all stages

of the manufacturing process - raw materials, in-process materials,

validated or tested materials, finished Goods and packing the

Goods, we also accept the third party International inspection

agencies to inspection the quality such as SGS,BV etc.

V. Could you offer designing service?

We have complete engineering team and we are using the state of the art designing and manufacturing software, Tekla, Advance Steel,Auto CAD, PKPM, MTS, 3D3S, Search etc. We are capable of designing and offering your economical solution to your needs if there is any inquiry. Please do not hesitate to contact which will be at your disposal at any time. Please note preliminary costing and design will be done at no extra cost.

IV:Is there any warranty available on the steel structure

buildings?

The steel structure buildings have limited warranty. Usually,steel structure houses with long use lifespan which can reach 50 to 100 years which depending on material quality, design standards, construction quality, and subsequent maintenance.

|