| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | EV Battery Safety Testing System |

|---|---|

| Brand Name: | Haida |

| Model Number: | HD-H206 |

| Certification: | CE,,ISO |

| Place of Origin: | China |

| MOQ: | 1 |

| Price: | Negotiation |

| Payment Terms: | L/C, T/T, D/A, D/P, Western Union, MoneyGram |

| Supply Ability: | 300 Sets per Month |

| Delivery Time: | 20 days after order confirmed |

| Packaging Details: | each set protected with resin fiber and PP film, then put into Strong wooden case with operation man |

| Smoke exhaust pipe: | diameter φ100mm, located at the back of the box |

| Impact height: | 0-1000mm (can be set) |

| Height display: | LED meter display |

| Displacement accuracy: | ≤±5mm |

| Impact method: | free fall |

| Control mode: | PLC touch screen control |

| Impact floor material: | No. 45 steel, thickness 30 password |

| Metal rod: | 15.8±0.2mm (5/8 inch) steel rod |

| Pressure relief door size: | 200x200mm |

| Inner box size: | 490x520x1430mm |

| Company Info. |

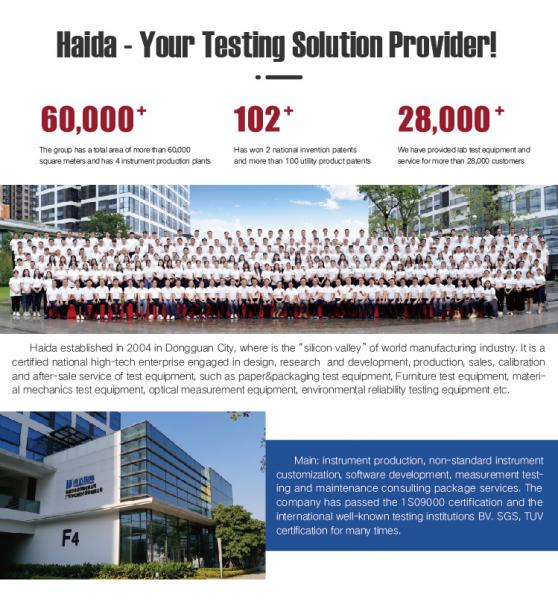

| Hai Da Labtester |

| Verified Supplier |

| View Contact Details |

| Product List |

Battery Impact Test Chamber

Description:

Battery Impact Test Chamber tests the safety performance of battery through different weights from different heights and different stressed area to impact. After a series of tests on this battery impact tester, the battery must not have flame or explosion. This device is a kind of battery testing equipment popular among battery manufacturers.Test

Test Standard:

UL 1642 UN 38.3

Product Advantages

1. High Precision

Ensures accurate simulation of real-world battery impact scenarios

for precise testing.

2. Safety First

Equipped with advanced safety mechanisms to protect users during

operation.

3. Durable Design

Constructed with high-strength materials for long-lasting

performance.

4. Customizable Tests

Supports adjustable impact force and angles to meet diverse testing

needs.

5. User-Friendly Interface

Intuitive control panel makes operation and monitoring simple.

6. Compliance Ready

Meets international testing standards like IEC, UL, and UN38.3.

Technical Parameters

| Model | HD-H206 |

| Weight | 9.1kg and 10kg; |

| Impact height | 0-1000mm (can be set); |

| Height display | LED meter display; |

| Displacement accuracy | ≤±5mm; |

| Impact method | free fall; |

| Control mode | PLC touch screen control; |

| Impact floor material | No. 45 steel, thickness 30 password; |

| Metal rod | 15.8±0.2mm (5/8 inch) steel rod; |

| Internal material | SUS#304 stainless steel plate, thickness 1.2mm; Teflon melt adhesive tape is applied to 1/3 of the place, high temperature resistance, corrosion resistance, insulation and easy to clean. |

| External material | Cold-rolled sheet baking varnish treatment, thickness 1.5mm; |

| Pressure relief door size | 200x200mm; |

| Smoke exhaust pipe | Diameter φ100mm, located at the back of the box; |

| Box door | A single door opens to the left, and an explosion-proof chain is installed on the side of the box door; |

| The maximum size of the battery tested | 200x200x200mm (width x depth x height); |

| Inner box size | 490x520x1430mm (width x depth x height); |

| Dimensions | 700x1000x1720mm (width x depth x height, including door lock); |

| Impact method | Lift the falling ball to a certain height and release it, and the falling ball falls freely in the vertical direction, without tilting or shaking; |

| Weight weight | 9.1kg and 10kg; |

| Impact height | 0-1000mm (can be set); |

| Height display | LED meter display; |

Details

Why choose us?

1.Design & Production : Solution Consultation for each order

Recommend the most cost -performance machine

Research & Develop the suitable one for Special- designed Model.

2.Shipping & Delivery: One-Stop Service

Production- Deliver to your door - Installation & Training-

Technical Support

3.Warranty

1 year warranty with lifetime technology support

4.After-Sale Service

React within 2 Hours

Video inspection & on-site service combined

FAQ

Q: How about your warranty?

Q: What is the order process?

Q: Can we visit your factory before order?

Q: Do you accept customization service?

Description:

BMS battery management testing system is used for parameter calibration, verification, and testing during the developm

|