| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Bottom Track Rollers |

|---|---|

| Brand Name: | YT |

| Model Number: | PC200-5 |

| Place of Origin: | China (Mainland) |

| MOQ: | 1PCS |

| Price: | Negotiable |

| Payment Terms: | L/C,T/T |

| Supply Ability: | 10000 PCS/Month |

| Delivery Time: | 5-30 Days |

| Packaging Details: | Standard Export Packaging |

| Material: | 50Mn Steel |

| Quality: | High Guarantee |

| Finish: | Smooth |

| Warranty Time: | 12-18 months |

| Colour: | Yellow or Black or Customer Required |

| Certification: | ISO9001-9002 |

| OEM: | Available |

| Company Info. |

| XIAMEN YINTAI MACHINERY CO., LTD. |

| Verified Supplier |

| View Contact Details |

| Product List |

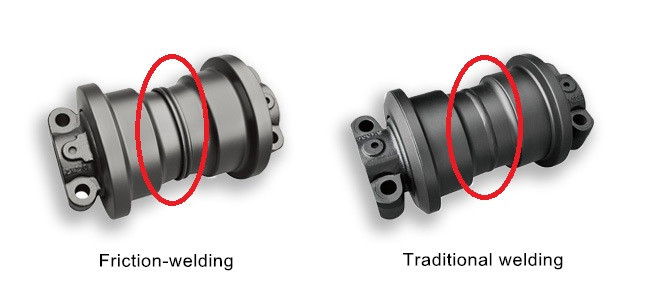

* Friction-welded track rollers exhibit superior wear resistance and extended service life due to their metallurgically bonded interfaces, which maintain structural integrity under sustained operational stresses.

* Consumption of raw material: the roller bodies of traditional track rollers are connected by the welding rod. but the friction ones are connected by the friction between rollers' bodies. So the friction-welding roller will be added to more raw material to make sure the roller is perfect to the standard size after welding.

* Inner parts: For the traditional rollers, the welding is done after two processes of machining, so the size of the inner parts is not so precise as friction-welding ones. For the friction-welding ones, after the welding, there is one more precise machining with concentric loing to make sure the conformity of inner size, this means the inner parts are more precise with a higher standard.

* World-class quality

* Factory sale directly with reasonable price

* 35 years' experience in Excavator & Bulldozer spare parts manufacturing

* Flexible payment terms including T/T, L/C and so on

* Fast delivery within 30 days after contract established

* Professional sales team, quality inspection, and report, maritime logistics guidance

* After-sale services: video technical support,24h online support

|