| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Stainless Steel Boiler Tube |

|---|---|

| Brand Name: | Yuhong |

| Place of Origin: | China |

| MOQ: | 1PC |

| Price: | Negotiable |

| Payment Terms: | TT, LC |

| Supply Ability: | 10000 tons/month |

| Delivery Time: | According to the quantity |

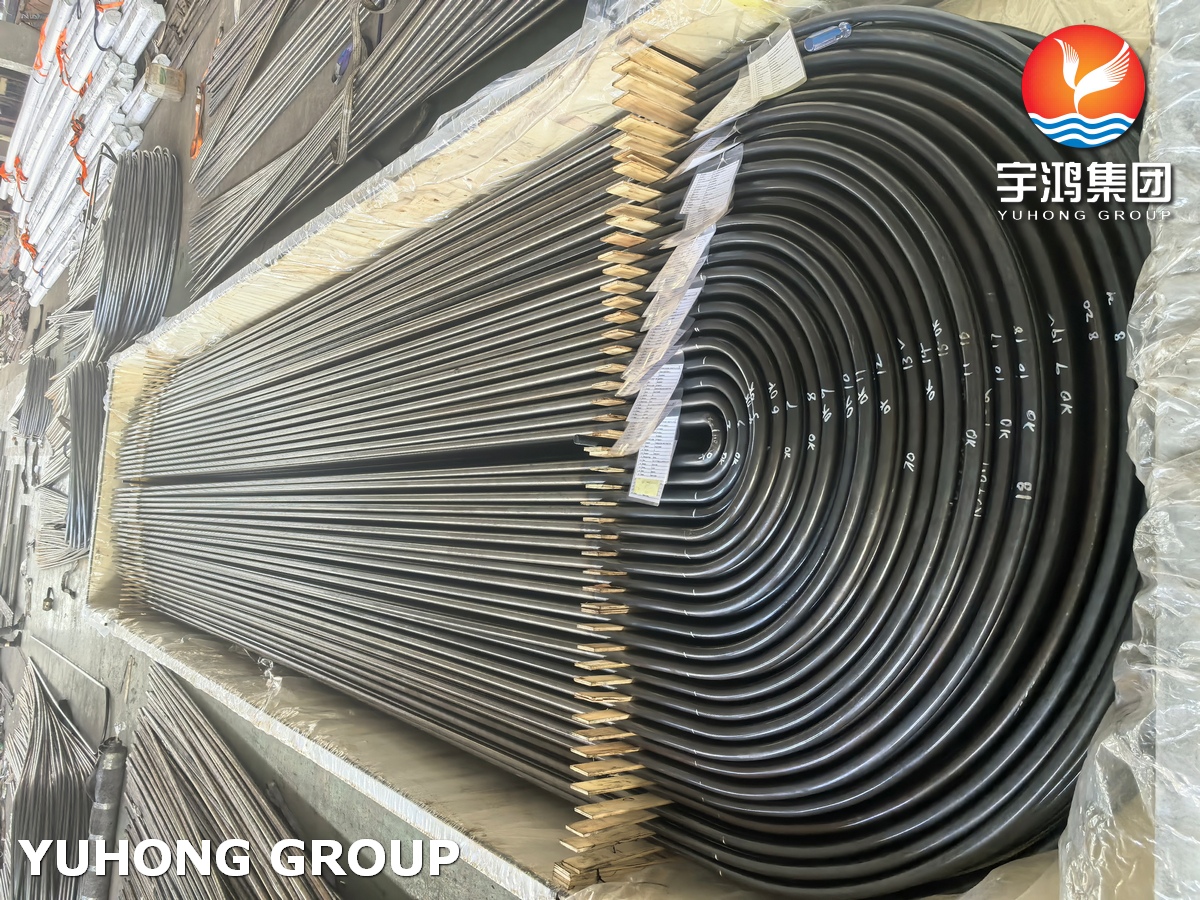

| Packaging Details: | WOODEN CASE WITH PLASTIC CAP |

| Tube Material: | A179, A106, A210 |

| Length: | Max 34M/PC |

| O.D.: | 6-50.8mm |

| W.T.: | 0.5-15mm |

| Testing: | UT, ET, HT, PMI |

| Product Name: | Stinless Steel U Bend Boiler Tube |

| Certification: | ABS, BV, DNV, CCS, LR |

| Company Info. |

| YUHONG HOLDING GROUP CO., LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

ASME SA213 TP304L U-Bend Boiler Tube – Applications & Key Features

SA213 TP304L is a low-carbon austenitic stainless steel (18% Cr, 8% Ni, low C) used in U-bend boiler tubes for high-corrosion resistance and flexibility in heat exchangers.

Primary Applications

1. Heat Exchangers & Condensers

2. Boilers & Superheaters

3. Petrochemical & Refining

4. Food & Pharmaceutical Processing

5. Marine & Desalination

Why Use SA213 TP304L U-Bend Tubes?

✔ Excellent corrosion resistance (vs. carbon steel in

acidic/chloride environments).

✔ Low carbon content (0.03% max) – prevents sensitization &

intergranular corrosion.

✔ Good weldability – no post-weld heat treatment required.

✔ High ductility – U-bends withstand thermal expansion stresses.

✔ Oxidation resistance up to ~800°C (1472°F).

Comparison with Other Grades

| Grade | Key Features | Best For |

| TP304L | Low carbon, general corrosion resistance | Most heat exchangers, food/pharma |

| TP316L | Added Mo (2-3%), better chloride resistance | Marine, desalination, harsh chemicals |

| TP321 | Ti-stabilized, resists sensitization | High-temp exhausts, aircraft |

| TP347 | Nb-stabilized, superior creep resistance | Superheaters, high-pressure steam |

Common FAQs

1. Can TP304L handle high-pressure steam?

2. Why U-bend instead of straight tubes?

3. How to prevent stress corrosion cracking (SCC)?

4. What’s the max operating temperature?

5. How to inspect U-bend tubes?

|