| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Vibratory Screening Machine |

|---|---|

| Brand Name: | EVERSUN |

| Model Number: | ZPS |

| Certification: | ISO,CE |

| Place of Origin: | CHINA |

| MOQ: | 1set |

| Price: | negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, MoneyGram, Western Union |

| Supply Ability: | 5000set/year |

| Delivery Time: | within 7-15 work days |

| Packaging Details: | Standard export wooden cases |

| Function: | Screening\separation\sorting\sieving |

| Keyword: | Industrial Sieve |

| Key Words: | Vibrating Screen |

| Maintenance: | Easy and Low Cost |

| Material: | Stainless Steel |

| Screening Size Range: | From 1mm to 100mm |

| Warranty: | 1 year |

| Mesh Size: | 2-500mesh |

| Diameter: | 400-2000mm |

| Screening Motion: | Circular, elliptical, or linear |

| Installation Method: | Floor-mounted or suspended |

| Company Info. |

| EVERSUN Machinery (Henan) Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Product description

The in-line screen is an efficient screening equipment, which

rotates the eccentric block on the shaft of the vibration motor,

converts the motor rotation into multi-directional force by

centrifugal force, and drives the screen body to make the material

move in an elliptical trajectory. It has a large processing

capacity and a large discharge port at the bottom to allow

materials to pass through the net quickly; Good applicability,

single and double motor, adjustable track, can be used single or

multi-layer; Energy saving and environmental protection, low energy

consumption and good sealing; Easy maintenance, compact structure,

external motor, easy to change the screen clean. Widely used in

food, chemical, pharmaceutical, mining, building materials and

other industries, screening all kinds of materials, improve product

quality and production efficiency.

Working principle

When the screen is working, the vibration motor starts to run as

the core power component. The eccentric block installed on the

shaft rotates at a high speed. Because the center of gravity of the

eccentric block deviates from the center of the rotating shaft,

centrifugal force will be generated during the rotation process.

This centrifugal force will break the balance of the motor, and

then drive the motor to vibrate. The motor is closely connected

with the screen body, and the vibration of the motor is transmitted

to the screen body, so that the screen body also begins to

high-frequency vibration. At this time, the material placed on the

screen surface, on the one hand by the sieve body vibration

generated by the exciting force, jumping forward on the screen

surface; On the other hand, the gravity of the material itself will

cause it to have a tendency to move down the screen surface. Under

the combined action of these two forces, the material smaller than

the size of the screen can pass through the screen and fall, while

the material larger than the size of the screen remains on the

screen surface and continues to move forward until it is discharged

from the discharge port, so as to achieve the screening of the

material.

Product Features

High screening efficiency: the unique vibration mode makes the

movement of the material on the screen surface reasonable, can be

quickly stratified and sifted through, the large discharge port

design also helps the material to be quickly discharged, greatly

improving the screening efficiency and large processing capacity.

High precision: By adjusting the parameters of the vibration motor, such as the Angle and weight of the eccentric block, the motion state of the material can be accurately controlled to meet the screening requirements of different precision, and the accurate classification of the material can be achieved.

Simple structure: mainly composed of screen frame, screen, vibration motor and base and other basic components, the overall structure is simple, there is no complex transmission device, easy installation, operation and maintenance, equipment stability is good, low failure rate.

Wide range of applications: whether it is fine powder materials, or large particles of block materials, or different properties of materials, such as dry, wet materials, etc., straight screen can be effective screening, in food, chemical, pharmaceutical, mining, building materials and other industries are widely used.

Environmental protection and energy saving: low energy consumption in the operation process, and the use of sealed design, can effectively prevent dust and material leakage, reduce environmental pollution, in line with environmental requirements.

Easy to clean: the design of the screen body is easy to clean, there is no dead Angle of material residue, and the screen replacement is convenient, which can quickly complete the disassembly and installation of the screen, reducing the maintenance cost and downtime of the equipment.

Product parameter

| Model | Power(kw) | Sieving diameter(mm) | Dimension(mm) |

| BZP-600 | 0.12 | 520 | 740*600*560 |

| BZP-800 | 0.18 | 720 | 1010*800*600 |

| BZP-1000 | 0.18 | 890 | 1200*970*640 |

| BZP-1200 | 0.25 | 1090 | 1430*1700*700 |

| BZP-1500 | 0.25 | 1390 | 1780*1470*760 |

| Machine can be customized based on your need | |||

Schematic diagram

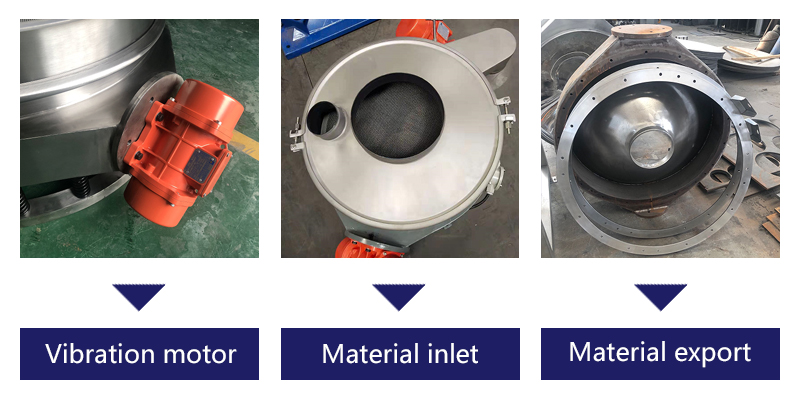

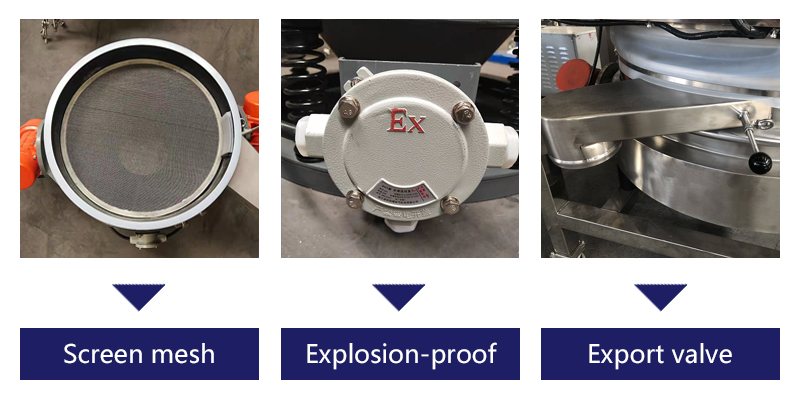

Detail display

Application

Packaging & Shipping

Why Choose us

About us

We have been specializing in the production of Screening and

conveying equipment for 13 years. China's vibrating screen industry top three. And we have done

matching and OEM for many large companies. Including the world's top vibrating screen manufacturer,

Sweco, USA, we have OEM

for his China region. And our products are often exported to

Australia, Thailand, Indonesia, New Zealand and other countries.

We welcome customers or dealers to visit our factory and will

arrange everything for you.Our factory address: West of the industrial and commercial office of Da

Zhaoying Town, Xinxiang City, Henan Province.

|