Industrial screening machine

Product description

The in-line screen is an efficient screening equipment, which uses

the eccentric block of the vibration motor to produce multiple

overlapping forces, so that the material produces an elliptical

motion track on the screen surface, so as to achieve screening. It

has the characteristics of large processing capacity, strong

applicability, energy saving and environmental protection, easy

maintenance, etc., widely used in food, chemical, pharmaceutical,

mining, building materials and other industries, can be rough

screening and precision screening of various materials, playing an

important role in industrial production.

Working principle

The in-line screen takes the vibration motor as the vibration

source, and the eccentric block on the motor shaft rotates with the

electric power of the motor, and produces centrifugal force due to

the eccentricity, which causes the motor to vibrate and transfer

the vibration to the screen body. When the screen body vibrates,

the material on the screen surface is jointly affected by vibration

and gravity, the vibration force makes it move forward by leaps,

and the gravity makes it move gradually to the bottom of the screen

surface, and the material less than the size of the screen falls

through the screen or is directly discharged, and the material

larger than the size of the screen continues to move forward and is

finally discharged from the discharge port. The in-line screen is

often set up with multiple layers of different screen sizes of the

screen surface, the material is screened by multiple layers, large

impurities are screened from the upper hole, the middle layer is

screened for medium particle size materials, and the lower layer is

obtained for the smallest particle size products, so as to achieve

the accurate classification of the material.

Product Features

1. Efficient screening: Unique vibration mode and large discharge

port design, so that the material can quickly pass through the

screening surface, large processing capacity, high screening

efficiency, can effectively improve production efficiency.

2. Adjustable accuracy: By changing the phase Angle and weight of

the eccentric block of the vibration motor, the movement track and

vibration intensity of the material can be adjusted, so as to meet

the screening accuracy requirements of different materials and

different particle sizes.

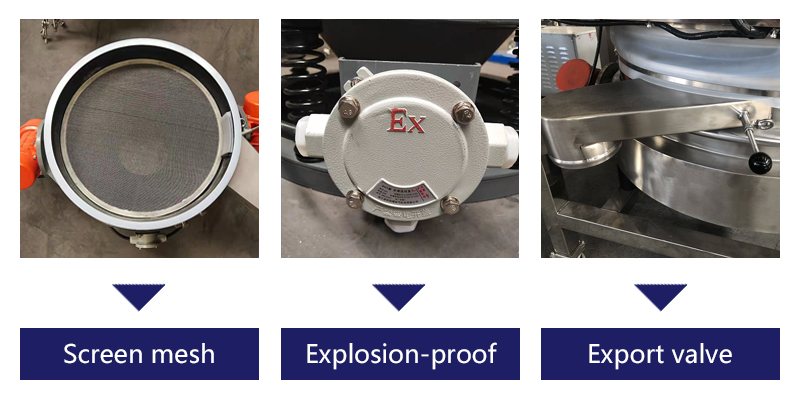

3. Simple structure: mainly composed of screen frame, screen,

vibrator and base and other components, the overall structure is

compact, reasonable design, easy installation, operation and

maintenance, high reliability of the equipment, long service life.

4. Widely used: It can be applied to different materials in a

variety of industries, whether it is fine materials in food,

chemical, pharmaceutical and other industries, or coarse granular

materials in mining, building materials and other industries, it

can be effectively screened and graded.

5. Environmental protection and energy saving: low energy

consumption in the operation process, and the use of sealing

design, can effectively prevent dust flying and material leakage,

reduce environmental pollution, in line with environmental

requirements.

6. Convenient cleaning: the internal and external structure of the

screen body is easy to clean, no sanitary dead corners, and the

screen replacement is convenient, which can quickly complete the

disassembly and installation of the screen, reducing the

maintenance cost and downtime of the equipment.

Product parameter

| Model | Power(kw) | Sieving diameter(mm) | Dimension(mm) |

| BZP-600 | 0.12 | 520 | 740*600*560 |

| BZP-800 | 0.18 | 720 | 1010*800*600 |

| BZP-1000 | 0.18 | 890 | 1200*970*640 |

| BZP-1200 | 0.25 | 1090 | 1430*1700*700 |

| BZP-1500 | 0.25 | 1390 | 1780*1470*760 |

| Machine can be customized based on your need |

Schematic diagram

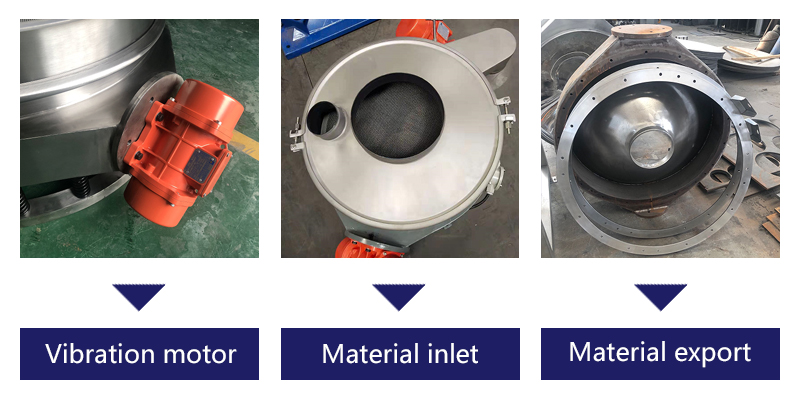

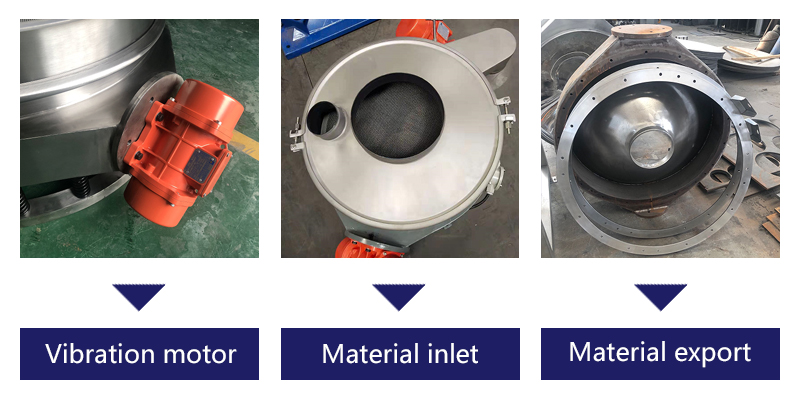

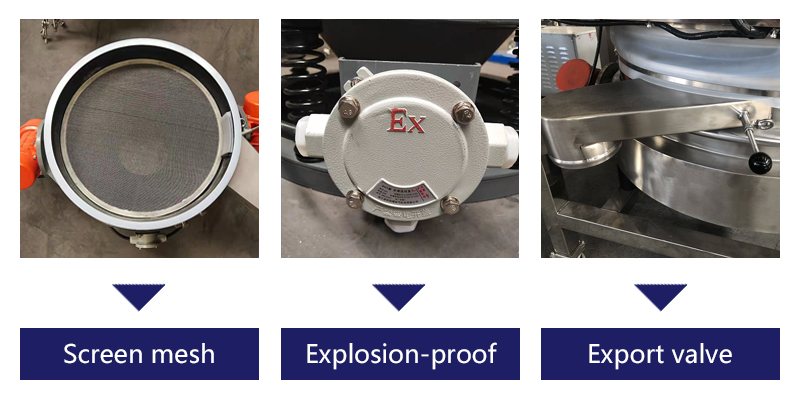

Detail display

Application

Packaging & Shipping

Why Choose us

About us

We have been specializing in the production of Screening and

conveying equipment for 13 years. China's vibrating screen industry top three. And we have done

matching and OEM for many large companies. Including the world's top vibrating screen manufacturer,

Sweco, USA, we have OEM

for his China region. And our products are often exported to

Australia, Thailand, Indonesia, New Zealand and other countries.

We welcome customers or dealers to visit our factory and will

arrange everything for you.Our factory address: West of the industrial and commercial office of Da

Zhaoying Town, Xinxiang City, Henan Province.