| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Metallic Powder Coat |

|---|---|

| Brand Name: | HSINDA |

| Model Number: | Customization |

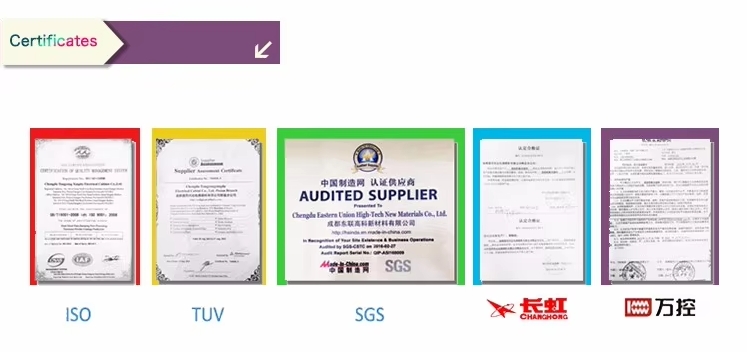

| Certification: | ISO9001; SGS; ROHS |

| Place of Origin: | China |

| MOQ: | 300KG |

| Price: | Negotiable |

| Payment Terms: | TT, Western Union, MoneyGram |

| Supply Ability: | 5000 tons each years |

| Delivery Time: | 7 days afterpayment |

| Packaging Details: | paper carton box,Single package size:39X29X39 cm,Single gross weight:26.0 kg |

| Product Name: | Metallic Pink Powder Coating |

| Usage: | metal surface |

| Application Method: | Electrostatic Spraying |

| State: | Powder Coating |

| Color: | Pink |

| Salt Spray: | 500hr |

| Humidity: | 1000hr |

| Chemical Resistance: | Good Resistance |

| Impact: | 50KG/cm |

| Gloss: | 4%~96% |

| Bending: | 2mm |

| Company Info. |

| Chengdu Hsinda Polymer Materials Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Glimmering Pink Polyester Powder Coating for Electronics Automotive Interiors UV and Moisture Resistant

Product Information

What is powder coating?

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint, which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat to form a hard, durable finish. The powder can be made from a variety of materials.

How Does Powder Coating Work?

The powder coating process involves several key steps:

1. Surface Preparation:

- The surface of the material to be coated is cleaned to remove dirt, oil, rust, or other contaminants.

- Common methods include chemical pretreatment, sandblasting, or phosphate coating to ensure proper adhesion.

2. Application:

- The powder is applied using an electrostatic spray gun, which gives the powder particles a positive electric charge.

- The charged particles are attracted to the grounded object, ensuring even coverage.

3. Curing:

- The coated object is placed in a curing oven, where the powder melts and flows into a smooth, uniform film.

- The heat causes a chemical reaction (for thermosetting powders) that hardens the coating, creating a durable finish.

Why Choose Powder Coating?

Powder coating is a versatile, durable, and environmentally friendly finishing solution that offers superior performance compared to traditional liquid paints. Its ability to provide a high-quality finish with minimal waste makes it a preferred choice for manufacturers and consumers alike.

Applications of Product

Powder coating is used across a wide range of industries and products, including:

-Automotive: Wheels, frames, engine parts, and accessories.

-Architecture & Construction: Window frames, doors, railings, and fencing.

- Furniture: Office furniture, outdoor furniture, and shelving.

- Appliances: Refrigerators, washing machines, and microwaves.

-Electronics: Computer cases, lighting fixtures, and tools.

- Industrial Equipment: Machinery, agricultural equipment, and storage tanks.

- Consumer Goods: Bicycles, sporting goods, and toys.

Instruction

Application Voltage | 60-90 KV |

Gun to Component Distance | 15-30CM |

Curing Temperature | 180-200℃,10 min-15 min |

storage stability

♦Store in ventilated, dry, clean room, temperature < 25℃ | ♦Relative humidity 50-65% |

♦Away from direct sunlight, fire, heat | ♦For best performance, use within 6 months |

Product process

Product test

Quality control

Test Item | Test Method | Test Result |

Film Thickness | ISO2360 | 60-80um |

Pencil Hardness | ASTMD 3363 | HB-H |

Bending | ISO1519 | ≤10mm |

Grid Test 1mm | ISO2409 | 0 Class |

Impulse Test | ASTMD2794 | Pass |

Cupping Test | ISO1520 | ≥8mm |

Heat Resistance 1000 hours | ISO6270-1 | Popping<1mm |

Shigh gloss mirror chrome sliver spray paint powder coating Spray 1000 hours | ISO9227 | Corrosion Spreading<1mm |

Hsinda powder coating, offers the best levelling and adhesion to metal surface, with above 60% DSM resin content.

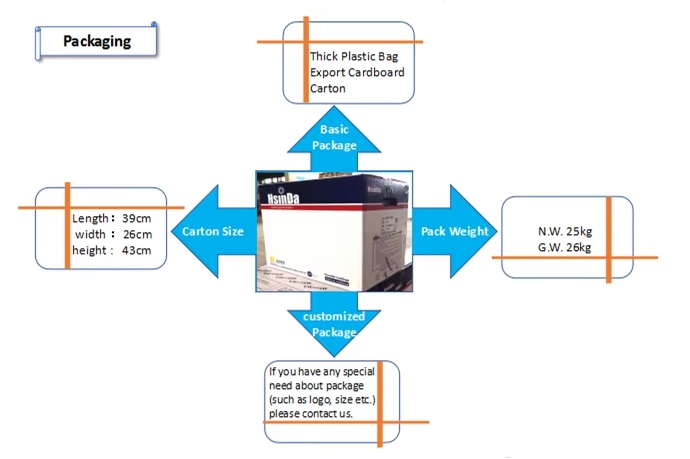

Packing & Shipping

Trade Terms | FOB, CIF, CRF, CNF |

Payment Terms | T/T, L/C, West Union, PayPal etc. |

Delivery time | 3-7 days after payment |

Packaging | Size: 39*26*43 (unit:cm) Weight: N.W. 25kg G.W. 26kg |

Shipping | By sea, by air, by courier |

Certificates

Company Information

Our Partners

Contact Us

Attn: Sue Su

Email: innocoat.sue@hsindapowdercoating.com

Phone/WhatsApp/Wechat: +86 13882064348

Instagram/Facebook: hsindapowdercoating_sue

|