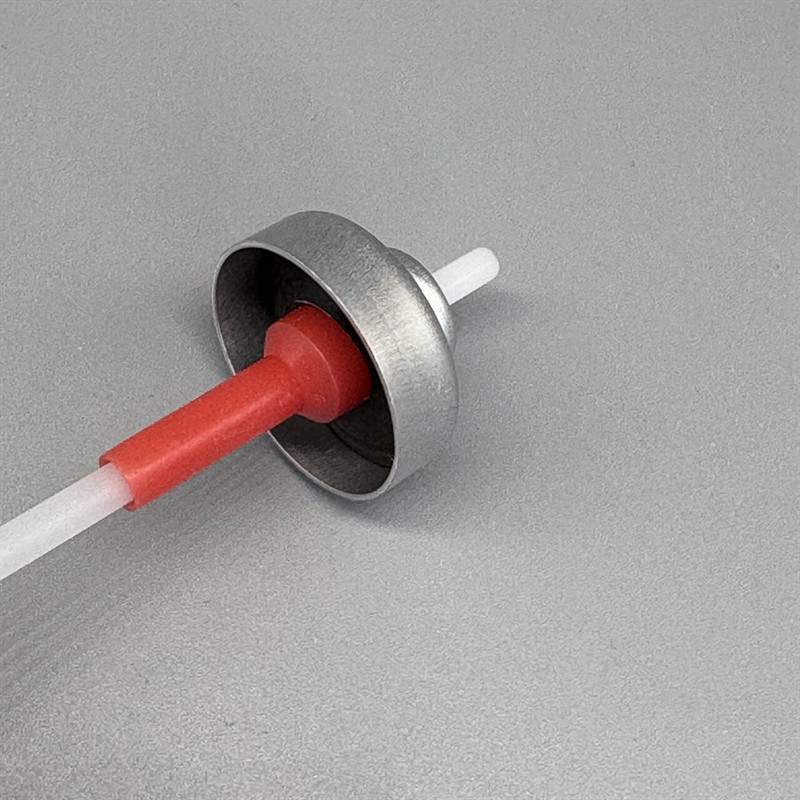

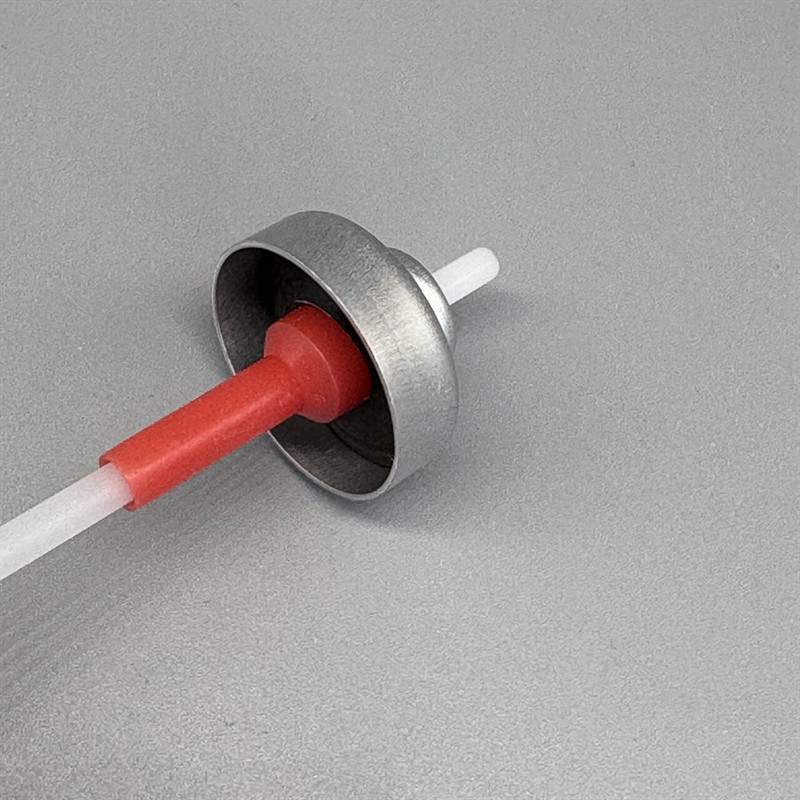

Compact & Precision 20mm Plastic Stem Metering Valve for Ink

Printing

This 20mm plastic stem metering valve is a game - changer in the

printing industry. Engineered with precision, it accurately

controls the flow of printing inks, which is the linchpin for

achieving consistent color output. Fabricated from a corrosion -

resistant plastic, its stem is built to last, withstanding the

harsh chemicals present in inks without succumbing to degradation.

The valve's compact size is a strategic advantage, allowing it to

be effortlessly integrated into printers, even in the tightest of

spaces, without compromising on functionality. Its adjustable flow

rate feature is a boon for printers, accommodating a wide variety

of printing requirements. Whether it's a high - volume commercial

print job that demands rapid ink dispensing or a small - scale

custom print that calls for meticulous control over the ink flow,

this valve rises to the occasion. With its reliable performance, it

empowers printers to produce high - quality printed materials that

meet the exacting standards of clients.

Bullet points:

- Accurate liquid dispensing.

- Chemical resistance.

- Consistent flow via smooth stem.

- Adjustable for experiments.

- Reliable performance.

Product Parameters

| Component | Part Description |

| Mounting cup | tinplate or aluminum |

| Dosage | 25ul , 35ul , 50ul , 75ul , 100ul , 120ul , 150ul |

| Stem | plastic stem or metal stem |

| Dip tube | according to the height of tin cans |

Specific application scenario:

In a large - scale commercial printing press, this valve is crucial

for multi - color printing jobs. It precisely dispenses the right

amount of ink for each color, ensuring that the final prints have

vibrant and sharp images. Whether it's printing brochures,

magazines, or posters, the consistent color output meets the high -

end requirements of clients. In small - scale printing shops, it is

used for custom - printed materials. It guarantees that each batch

of products, such as business cards or wedding invitations, has the

same color quality, which is essential for maintaining customer

satisfaction. For digital printing machines, it plays a key role in

achieving accurate color reproduction.

Factory production floor:

The production facility uses renewable energy sources to

manufacture the valves. Each valve is quality-tested to ensure it

meets green building standards.Future aerosol valve manufacturers has been a seasoned valve

product manufacturer and exporter for more than ten years. Our high

quality products, such as aerosol valves, aerosol caps and aerosol

cans are exported to more than 50 countries in Europe, America and

Asia. Our main products are air freshener aerosol valve,

insecticide spray aerosol valve, butane gas aerosol valve,

carburetor cleaner aerosol valve, ribbon spray aerosol valve, snow

spray aerosol valve,paint spray aerosol valve, fluid spray aerosol

valve, portable stove gas aerosol valve, 360 degree aerosol valve,

powder spray aerosol vave. Also we have expanded the export market

of aerosol metering valves, aerosol caps and aerosol cans. All

products have won high reputation from our clients all over the

world.

These activators are manufactured with precision and attention to

detail. The production process involves advanced technology and

quality control checks. Workers test each activator to ensure it

meets the highest standards.

Packing and transportation

Valves are packed in biodegradable materials and shipped in

optimized packaging to reduce carbon footprint.Future aerosol valve manufacturers has been a seasoned valve

product manufacturer and exporter for more than ten years. Our high

quality products, such as aerosol valves, aerosol caps and aerosol

cans are exported to more than 50 countries in Europe, America and

Asia. Our main products are air freshener aerosol valve,

insecticide spray aerosol valve, butane gas aerosol valve,

carburetor cleaner aerosol valve, ribbon spray aerosol valve, snow

spray aerosol valve,paint spray aerosol valve, fluid spray aerosol

valve, portable stove gas aerosol valve, 360 degree aerosol valve,

powder spray aerosol vave. Also we have expanded the export market

of aerosol metering valves, aerosol caps and aerosol cans. All

products have won high reputation from our clients all over the

world.

These activators are manufactured with precision and attention to

detail. The production process involves advanced technology and

quality control checks. Workers test each activator to ensure it

meets the highest standards.

FAQ:

Q: Can it be used in outdoor watering systems?

A: Yes, its durable construction makes it suitable for outdoor use.

Q: How accurate is the metering?

A: It provides highly precise metering for consistent flow.

Q: Is the plastic stem strong?

A: The plastic stem is engineered to be strong and reliable.

Q: Can it be easily replaced if needed?

A: Yes, its design allows for easy replacement.

Q: What kind of maintenance does it require?

A: Regular cleaning to keep the valve operating smoothly.