| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Double Cone Blender |

|---|---|

| Brand Name: | EVERSUN |

| Model Number: | SYH |

| Certification: | ISO,CE |

| Place of Origin: | CHINA |

| MOQ: | 1set |

| Price: | negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, MoneyGram, Western Union |

| Supply Ability: | 5000set/year |

| Delivery Time: | within 7-15 work days |

| Packaging Details: | Standard export wooden cases |

| Function: | mixing and drying |

| Shape: | Double Cone |

| Safety Features: | Emergency Stop Button, Safety Grid |

| Volume: | 300-8000L |

| Speed: | Adjustable |

| Design Features: | Dust-Tight/Dust-Controlled |

| Certifications: | CE, ISO, GMP |

| Key Advantages: | Easy Cleaning/Maintenance |

| Adjustable Frequency: | 3 to 17 RPM |

| Capacity: | 5-5000 liters |

| Mixing Type: | Tumbling |

| Company Info. |

| EVERSUN Machinery (Henan) Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Product description

The double cone mixer is like an efficient material fusion master, and its main structure is formed by two cones docking, just like an hourglass shape. The whole machine is made of stainless steel, which not only has excellent corrosion resistance, but also ensures that the material is not contaminated during the mixing process. Rotary supports at both ends of the device drive the double-cone barrel stably and precisely, allowing it to run smoothly at just the right speed. When the material is put into the double-cone mixer, with the rotation of the cylinder, the material is first thrown high in the cylinder, and then free fall, so the cycle is repeated, under the synergistic effect of gravity and mechanical force, the material of different nature and different particle size is quickly and evenly interwoven and fused. From fine powder raw materials to granular materials, the double-cone mixer can perfectly mix them in a short time, providing high-quality and uniform material basis for the subsequent production process. It is widely used in pharmaceutical, chemical, food and many other industries, and is a powerful equipment to ensure production efficiency and product quality.

Working principle

The double cone mixer works by rotating the barrel around the horizontal axis. When running, the material in the cylinder rises to a certain height with the wall of the cylinder, and falls freely under the influence of gravity, forming a "throwing" movement. Because of the special shape of the double cone, the movement track of the material is complex, both up and down throwing and axial and radial flow, which promotes the all-round movement of the material. In this process, different parts of the material interspersed with each other to achieve diffusion mixing; The material as a whole will also produce macroscopic convection, flow from one end of the cylinder to the other end, achieve convective mixing, diffusion and convection synergistic effect, can initially mix the material in a short time. At the same time, friction and shear force will be generated between the particles of the material, between the particles and the wall of the cylinder, as well as between the possible stirring blades, which will break up the particles of the material and fill the small particles into the space of the large particles. Especially for the viscous or easy to agglomerate materials, the shear effect can effectively break the agglomerates, further improve the mixing uniformity, and ensure the full and efficient mixing of the materials.

Product characteristics

1. High mixing uniformity: The double-cone mixer through the unique double-cone structure and rotating motion mode, so that the material in the cylinder to produce a complex movement trajectory, including dropping, axial and radial flow, etc., can achieve a variety of mixing mode synergistic effect, so as to achieve a high mixing uniformity, even different particle size, different density of the material can be mixed very evenly.

2. High mixing efficiency: its reasonable structural design and efficient movement mode make the material can complete the mixing process in a short time, compared with some other types of mixing equipment, can effectively improve production efficiency and reduce the production cycle.

3. Wide range of application: It can be applied to a variety of types of material mixing, including powder, granular and some paste materials with small viscosity. It is widely used in pharmaceutical, chemical, food, feed and other industries, and can meet the diversified needs of different industries for material mixing.

4. Simple structure, easy operation: mainly composed of double cone barrel, rotating support device and drive device, etc., relatively simple structure, easy to maintain and maintain. The operation of the equipment is also more convenient, the staff can master the operation method after simple training, and can accurately control the mixing time, speed and other parameters.

5. Low pollution: Usually the use of fully closed cylinder design, in the mixing process can effectively prevent material leakage, reduce dust flying, avoid pollution to the working environment, but also to prevent external impurities into the material, to ensure the quality of the material.

6. Easy to clean: the internal structure of the double cone mixer is smooth, no dead Angle, easy to clean. After the completion of the mixing work, it can be convenient to clean the inside of the cylinder, ensure the cleanliness of the equipment, and meet the health requirements of different material mixing, especially for the pharmaceutical and food industries with high requirements for health conditions.

Application

The double cone blender, with its excellent structure and reasonable design concept, features rapid mixing, uniform mixing, ease of operation, convenient cleaning,urdiness, compact structure, and high technological content. It is widely used in industries such as pharmaceuticals, food, pesticides, zinc oxide, detergents medicine, compound fertilizers, feed, oil, metallurgy, building materials, coatings,

dye pigments, additives, calcium carbonate, biology, ceramics, chemicals fragrance, chicken essence, seasonings, tea, chemical building materials, coatings, plastics and rubbers, seasonings, etc., for mixing powdered materials.

Product parameter

| Model | W-300 | W-500 | W-1000 | W-1500 | W-2500 | W-4000 | W-6000 | W-8000 |

Production capacity (kg/time) | 150 | 250 | 500 | 750 | 1250 | 2000 | 3000 | 4000 |

Full volume (cubic meter) | 0.3 | 0.5 | 1 | 1.5 | 2.5 | 4 | 6 | 8 |

Mixing time (min) | 4-8 | 4-8 | 6-12 | 6-12 | 6-12 | 6-15 | 6-15 | 6-15 |

Motor power (KW) | 1.1 | 2.2 | 3 | 4 | 5.5 | 7.5 | 11 | 15 |

| Cylinder speed (RPM) | 15 | 15 | 12 | 12 | 12 | 10 | 10 | 10 |

Dimension (L*W*H) | 1680*650 *1600 | 2080*750 *1900 | 2150*850 *2100 | 2300*1600 *3100 | 2500*1000 *2450 | 2980*1580 *2800 | 3500*1800 *3000 | 3980*2000 *3200 |

| Weight (kg) | 310 | 550 | 800 | 950 | 1650 | 1880 | 2350 | 2680 |

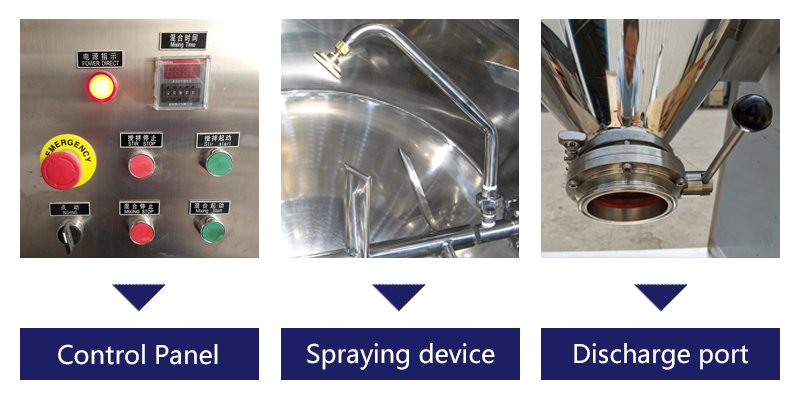

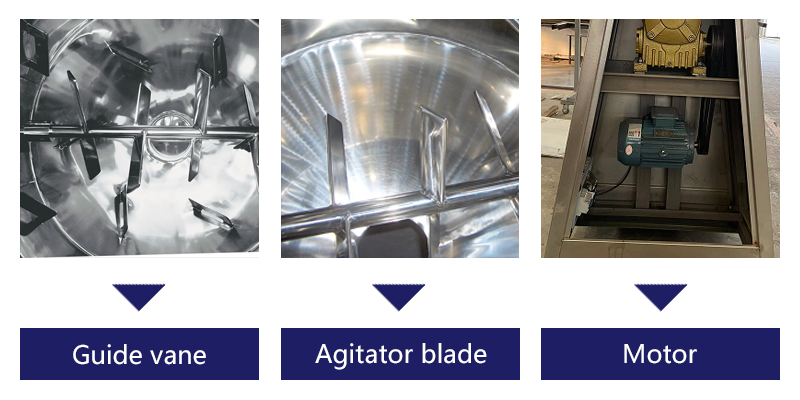

Detail display

Product display

Packaging & Shipping

Why choose us

About us

Company Profile

|