| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Boiler Fan |

|---|---|

| Brand Name: | SIMO BLOWER |

| Model Number: | 4-10 |

| Certification: | CE, ISO9001:2008 |

| Place of Origin: | CHINA |

| MOQ: | 1 |

| Price: | $500-1000 |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 300 Set/Sets per Month centrifugal fan and axial fan manufacturer |

| Delivery Time: | 35days(To be negotiated) |

| Packaging Details: | 1.export wooden case packing 2.bare package with steel pallet 3.other export package |

| Feature: | High Performance Strong suction |

| Warranty: | 1 Year |

| Bearing cooling: | Air Cooling Or Circulating Water Cooling |

| Main shaft: | High-strength carbon structural steel |

| Lubrication: | Oil bath lubrication |

| Impeller: | Dynamic Balanced |

| Power: | 15-700kw |

| Speed: | 960-2900r/min |

| Air volume: | 10696-952530m³/h |

| Company Info. |

| Xinxiang SIMO Blower Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

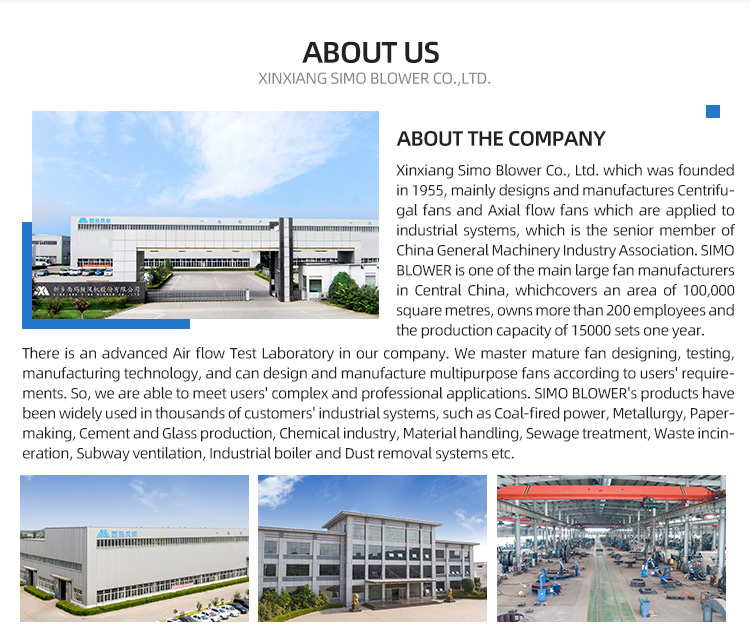

G4-10 and Y4-10 series ventilation and induced draft fans are suitable for the ventilation and induced draft fan systems of 2~670T/h steam boilers in thermal power plants.

It can also be used for mine ventilation and general ventilation without other special requirements; Mainly used to meet the needs of large air flow applications, low noise and high efficiency.

They can transport clean gas, dusty gas, flammable gas, corrosive gas, powder or granular materials at normal temperature or high temperature.

Typical applications include: building ventilation, mine ventilation, smoke evacuation, drying, clinker cooling, transport of gas, transport of lightweight materials, blasting and drafting of industrial boiler systems, and supply of air to kiln systems/incinerator systems and induced air, air purification equipment, industrial dust collector systems, etc.

In addition to the industrial system, it is also frequently used in agriculture and civil applications and the most versatile range of centrifugal fans.

1. It can work stably at a high medium temperature, and can output a large gas flow with low noise when the pressure requirement is met.

2. The fan blade placement angle is optimized, more wear-resistant and longer service life.

3. The air damper can be used to flexibly adjust the pressure and flow of the fan during operation. It is also possible to select a variable frequency motor, with adjust the pressure and flow of the fan by changing the speed.

4. For the material of impeller and main shaft, we will choose high-strength carbon steel, low-alloy steel, high-temperature alloy steel, high temperature resistant high-strength alloy steel under different working conditions temperature and working speed, so that the impeller and main shaft still maintains a reliable strength at high temperature.

5. Fan systems with impeller diameters less than 1400 mm at normal temperature do not require additional bearing cooling devices, reducing users’ investment and maintenance.

6. The impeller is annealed to eliminate the internal stress generated during welding, ensuring that the impeller does not undergo creep and cracks.

7. The weld of the impeller and the main shaft are ultrasonic flaw detection to ensure that there are no welding defects and material defects to ensure strength.

8. The impeller is subjected to a high standard of dynamic balance correction to ensure stable operation of the fan.

9. There are a variety of accessories to choose from.

| Series no. | 4-10 series | Feature selection | |||||

| Normal | anti-corrosion | wear-resisting | High temperature | anti-explosion | Remarks | ||

| Performance | Impeller diameter | 400-3000mm | |||||

| Rotation speed | ≤4000rpm | ||||||

| Pressure range | 615-8302Pa | ||||||

| Flow range | 10696-952530㎥/h | ||||||

| Structure | Blade type | Backward, Straight, Aerofoil type | |||||

| Impeller support | SWSI(Single Width, Single Inlet), DWDI(Double Width, Double Inlet), Overhung type | ||||||

| Lubrication method | Oil bath lubrication, grease lubrication, lubrication oil station | Can be specified | |||||

| Cooling method | Air cooling, Water cooling, Oil cooling | Can be specified | |||||

| Driven mode | Direct driven, Coupling driven, Belt driven | Can be specified | |||||

| Gas composition | Gas temperature | Normal | Customer request | Customer request | ≥250℃ | Customer request | |

| gas characteristic | Clean gas | Corrosive gas | Particulate dust | High temperature gas | Flammable gas, explosive gas | ||

| System configuration | Motor brand | Chinese famous brand, ABB, Siemens, WEG etc | Can be specified | ||||

| Impeller | High quality carbon steel | FRP, Stainless steel, Rubber Lining | Wear-resistant layer or wear-resistant liner, ceramic patch | High temperature high quality alloy steel | FRP, Aluminum alloy | Can be specified | |

| Air inlet cone | High quality carbon steel | FRP, Stainless steel, Rubber Lining | High quality carbon steel | High quality carbon steel | High quality carbon steel | Can be specified | |

| Casing | High quality carbon steel | FRP, Stainless steel, Rubber Lining | High quality carbon steel | High quality carbon steel | High quality carbon steel | Can be specified | |

| Air damper | High quality carbon steel | FRP, Stainless steel, Rubber Lining | High quality carbon steel | High quality carbon steel | High quality carbon steel | Can be specified | |

| Main shaft | High strength carbon steel, Alloy structural steel | Can be specified | |||||

| Bearing | ZWZ, SKF, FAG, NSK | Can be specified | |||||

| Bearing housing | Cast iron | ||||||

| Foundation bolts | GB799-1988 | ||||||

| Option parts | System base frame, Protective screening, Silencer, Inlet & Outlet flexible connections, Inlet & Outlet counter flange, Air damper, Electric actuator, Shock absorber, Diaphragm coupling, Fluid coupling, Motor rain cover, Temperature sensor, Vibration sensor, Soft starter, Inverter, Special Electrical Motor, System monitoring Instrument. | ||||||

|