| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Quick Connect Coupling |

|---|---|

| Brand Name: | Seelong |

| Model Number: | TF230 |

| Certification: | CMC, ISO9001, CE |

| Place of Origin: | China |

| MOQ: | 1 |

| Price: | Negociated |

| Payment Terms: | T/T |

| Supply Ability: | 1000 sets per month |

| Delivery Time: | 5-7 working weeks |

| Packaging Details: | Seaworthy Plywood |

| Connection Type: | External thread |

| Seal material: | The main seal is made of nitrile rubber (NBR) by default, and other materials can be selected according to customer requirements |

| Body Material: | Corrosion-resistant stainless steel and aluminum alloy, other materials can also be selected according to customer needs |

| Customized: | YES |

| Operating pressure: | 0-50 bar |

| Operating temperature: | -15℃ - +100℃ |

| Applicable medium: | Regular fluid or non-corrosive gas |

| Applicable interface: | External thread: including metric thread, pipe thread, taper pipe thread and American standard taper pipe thread |

| Company Info. |

| Seelong Intelligent Technology(Luoyang)Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

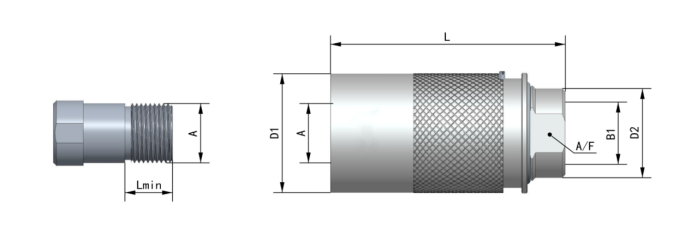

TF230 Series Well-crafted Threaded Stainless Steel And Aluminum Alloy Sleeve Type Quick Connect Coupling

TF230 series quick connectors are clamped with sleeve clamp claws,

which are mostly used for manual testing. It can realize the

pressure and Air tightness Testing of external threaded parts, as

well as functional operations such as filling, plugging and

emptying.

When the sleeve clamp claw is locked, the connection is completed instantaneously. The operation is simple, safe and reliable, which greatly improves the test efficiency and connection reliability. Front seal, easy to maintenance.

TF230 Quick Connector Advantages

1) Exquisite design, compact structure, to save space for customers to the greatest extent.

2) The unique knurled process on the surface of the Sleeve makes it more convenient to operate.

3) Unique automatic alignment connection design, no adjustment, can be operated with one hand, improve the test connection efficiency.

4) According to customer needs, an anti-slip mechanism can be installed in the tail. The unique anti-trip design can prevent the connection from being disconnected abnormally during the test due to excessive vibration of the parts to be tested or customer's misoperation, which results in danger.

5) Axial docking, linear flow direction, reduce pressure drop, to ensure the maximum efficiency of the pipeline system.

6) End seal, simple replacement, easy to maintain.

TF230 Series Technical Parameters

| Applicable interface | External thread: including metric thread, pipe thread, taper pipe thread and American standard taper pipe thread |

| Body material | Corrosion-resistant stainless steel and aluminum alloy, other materials can also be selected according to customer needs |

| Seal material | The main seal is made of nitrile rubber (NBR) by default, and other materials can be selected according to customer requirements |

| Applicable medium | Regular fluid or non-corrosive gas |

| Mode of operation | Sleeve type |

| Operating pressure | 0-50 bar |

| Operating temperature | -15℃ - +100℃ |

| Leakage rate* | 10-4 Pa×m3/s |

* This is the minimum leakage rate of the standard products; We can provide devices with a lower leakage rate on demand; This depends on the detailed specifications provided by the customer (test method, test temperature and test pressure) and the quality of the sample provided by the customer (i.e. the surface treatment of the sealing surface, roughness and dimensional tolerances).

TF230 Series Dimensions (unit: mm)

| Body Number | Fluid Hole B1 | D1 | D2 | L | A/F |

| 2 | G1/8” | 25 | 17 | 74 | 15 |

| 3 | G1/4” | 30 | 22 | 74 | 19 |

| 4 | G3/8” | 35 | 27 | 78 | 24 |

| 5 | G1/2” | 40 | 30 | 78 | 27 |

| 6 | G3/4” | 45 | 33 | 90 | 30 |

| 7 | G3/4” | 50 | 37 | 90 | 32 |

| 8 | G3/4” | 55 | 40 | 90 | 36 |

TF230 Series Application

1. Engine testing industry

2. New energy testing industry

3. Instrument testing

4. Refrigeration and air conditioning industry

5. Gas, liquid fast filling

6. General industrial quick seal

Company Profile

Seelong Intelligent Technology (Luoyang) Co., Ltd. is a high-tech enterprise specializing in equipment measurement, control, design, manufacturing, and sales services for power engineering systems in various fields such as aerospace, automotive, and new energy; The company is located in the beautiful peony city of Luoyang.

The main products are quick connect coupling, AC dynamometer,

torque sensor, measurement and control system and condition

guarantee system and other products. Establish a complete sales

service system, adhering to the business philosophy of quality for

survival and service for development, to provide users with power

engineering measurement and control solutions in various fields.

Seelong's advanced design philosophy and rich industry experience

give the company a technological advantages ahead of competitors in

the same industry, and the company's products can better meet the

actual market demand. Seelong has passed CE certification, ISO9001

quality system certification, AAA level enterprise certification,

obtained more than ten invention patents, and two software

copyrights. It has provided professional equipment and services to

more than a hundred users both domestically and internationally,

The enterprise has won the trust of domestic and foreign customers

with its cost-effective products and high-quality services, and has

established a long-term win-win strategic partnership.

The company always adheres to the business philosophy of "taking

technological innovation as its mission and quality service as its

purpose", constantly surpassing the advanced level in the same

industry, integrating into the world, measuring and controlling the

future, and creating high-quality products.

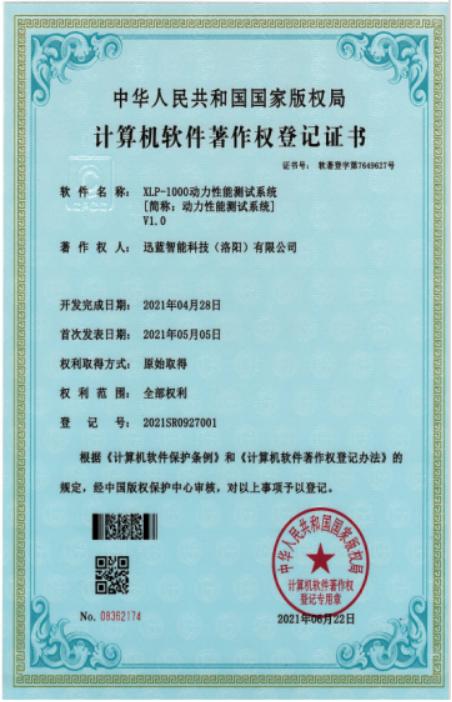

Company Certificates

Packaging and Shipping

FAQ

Q: What's the minimum order quantity for our cooperation?

A: We support small trail order of 1 pcs for stock products.

Q:How can I learn more about the products?

A: Please leave your email and we will send you your electronic

sample book.

Q: What's your payment term?

A: Normally 40% T/T deposit, pay in full before shipment.

Q:What's the lead time for my orders?

A: Dynamometers production cycle is 6-8 weeks, sensors production

cycle is 2-3 weeks, other products please contact with us.

Q: How do we get the overall solution of the test bench?

A: Leave us your email, our technical staff will communicate with

you about the detailed plan.

Q: Can I come to visit your factory?

A: Sure, you are always welcomed to have a visit.

|