| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Rubber Vulcanizing Press Machine |

|---|---|

| Brand Name: | Beishun |

| Model Number: | XLB-1000*1000/5MN |

| Certification: | ISO/CE/SGS |

| Place of Origin: | Qingdao,China |

| MOQ: | 1set |

| Price: | Negotiable |

| Payment Terms: | T/T,L/C |

| Supply Ability: | 30sets/month |

| Delivery Time: | 40day |

| Packaging Details: | Wooden box/container |

| Material: | Steel |

| Heating Type: | Electrical or Oil or Steam |

| Loading Port: | Qingdao, China |

| Type: | Hydraulic Press |

| Working Layers: | Customized |

| Pressure Range: | 16.8(mpa) |

| Working Layer: | 1 |

| Power: | 7.5-75KW |

| Max Temperature: | 300°C |

| Structure: | Frame type or column type |

| Piston: | Chilled Cast Iron HS 72-75 Hardness |

| Heaqting Way: | electrical, steam or oil |

| Working Layer: | 1,2,4 |

| Platform Size: | 1000*1000mm |

| Safety Device: | Safety Curtain |

| Company Info. |

| Qingdao Beishun Environmental Protection Technology Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Good After-Sales Rubber Hydraulic Molding Machine Is Used To Manufacture Rubber Shock-Absorbing Pads And Rubber Shock-Absorbing Bases

The manufacturing machinery for rubber anti-vibration pads and rubber anti-vibration bases typically involves a series of specialized equipment and processes. Below is an overview of the key machinery and steps involved:

Internal Mixer (Banbury Mixer): Used to mix rubber with fillers, vulcanizing agents, and other additives.

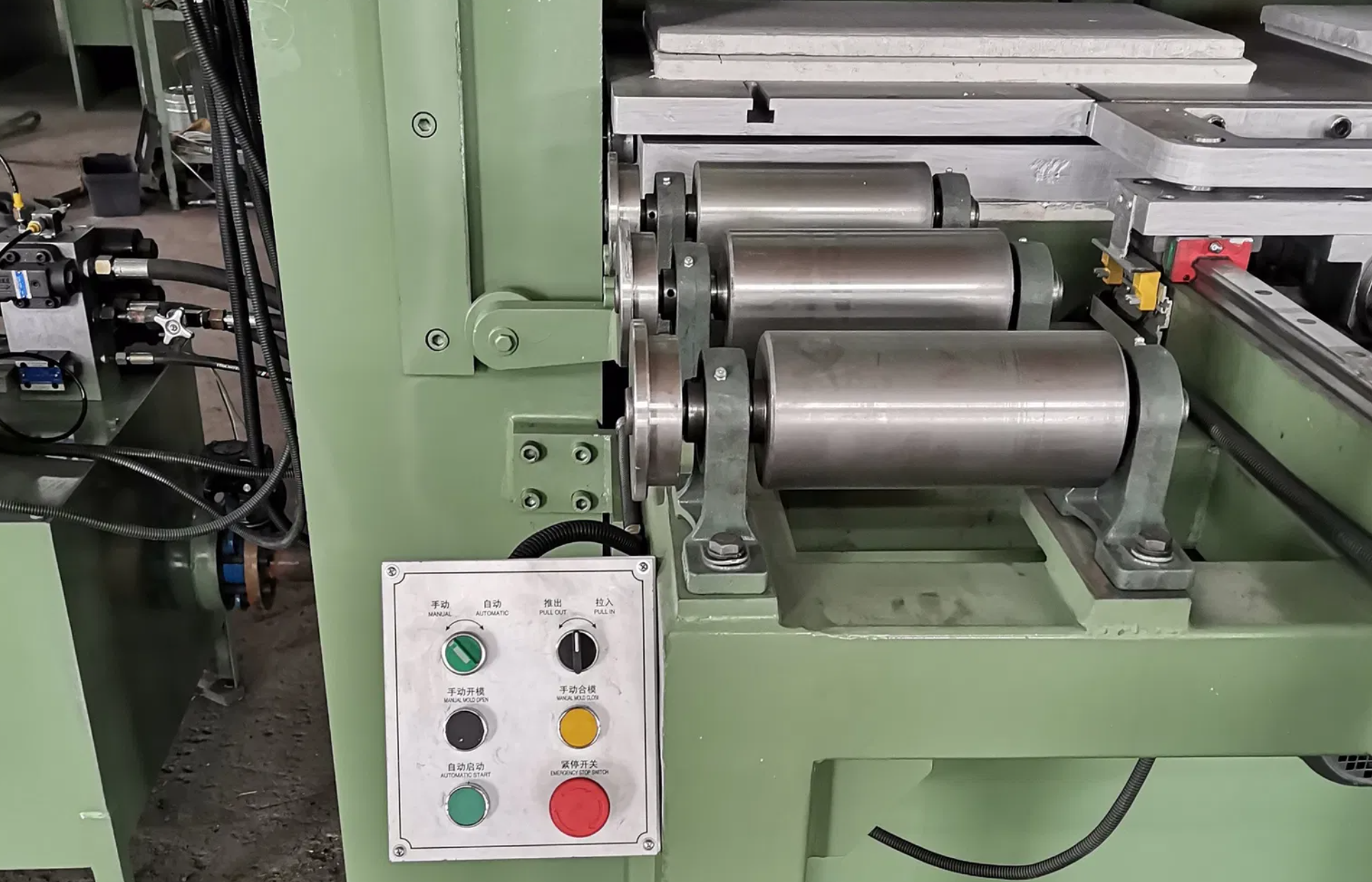

Two-Roll Mill: Further mixes and plasticizes the rubber compound.

Compression Molding Press (Flat Vulcanizing Press): Uses heat and pressure to shape rubber into the desired form.

Injection Molding Machine: Injects rubber into molds, suitable for complex shapes.

Extruder: Produces long strips or tubular rubber products.

Autoclave (Vulcanization Tank): Provides high temperature and pressure for vulcanization.

Continuous Vulcanization Line: Used for high-volume production.

Trimming Machine: Removes excess flash or burrs from the molded parts.

Grinding Machine: Smooths the surface of the products.

Washing Machine: Cleans the finished products to remove any residues.

Durometer: Measures the hardness of the rubber.

Tensile Testing Machine: Tests tensile strength and elongation.

Compression Set Tester: Evaluates the compression properties.

Robotic Arms: Used for handling and assembling parts.

Conveyor Systems: Links different stages of production for efficiency.

Steel Molds: Used for compression or injection molding.

Aluminum Molds: Suitable for small batches or prototyping.

Cooling Systems: Used to cool molds and finished products.

Air Compressors: Provide compressed air for pneumatic equipment.

Exhaust Gas Treatment Systems: Handle gases emitted during vulcanization.

Wastewater Treatment Systems: Treat production wastewater.

Automatic Packaging Machines: Used for packaging the final products.

These machines and processes work together to manufacture high-quality rubber anti-vibration pads and bases, ensuring both product performance and production efficiency.

Technical parameter;

| Type | XLB-D(Y)1000*1000*1 | XLB-D(Y)1600*1600*1 | XLB-D(Y)1400*2600*1 |

| (MN)Nominal mounding power | 2.50 | 8.00 | 10.00 |

| Working layer number | 7 | 7 | 7 |

| (mm)Piston stoke | 500 | 500 | 500 |

| (KW)Main motor power | 3.0 | 22.5 | 22.5 |

| (mm)Plate clearance | 70 | 80 | 80 |

| Calefaction manner | Steam Electricity | Steam Electricity | Steam Electricity |

| Configuration | Frame | Frame | Frame |

| Electric pipe heating power(kw) | 12 | 28.8 | 22.5 |

|