Our Basic Series Double Station Machine

Welcome to explore our remarkable basic series machine, a double -

station wonder that stands out in the mechanical industry. This

machine is not just a product; it represents our commitment to

quality, innovation, and customer satisfaction.

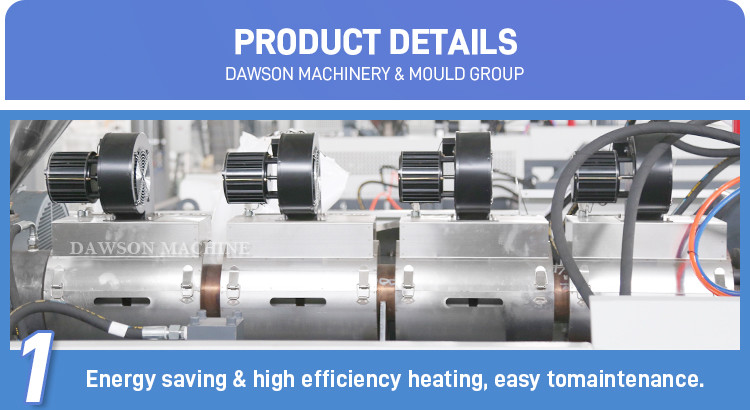

Design and Manufacturing Excellence

The main parts of this machine are the result of our in - house

design and manufacturing prowess. Our team of highly skilled

engineers and technicians has poured their expertise into every

aspect of its creation. The double - station design is a testament

to our understanding of efficiency and productivity requirements in

modern manufacturing processes.

For the design phase, our engineers utilize state - of - the - art

CAD (Computer - Aided Design) software. This allows them to create

highly detailed 3D models of each component, ensuring precise fit

and function. They take into account factors such as mechanical

stress, operational speed, and ease of maintenance during the

design process. For example, the layout of the two stations is

optimized to minimize the time required for switching between

different operations, thereby increasing overall throughput.

When it comes to manufacturing, we operate in a state - of - the -

art facility equipped with advanced CNC (Computer Numerical

Control) machines. These machines enable us to achieve extremely

tight tolerances, ensuring that each part is manufactured to the

highest standards. We source only the finest raw materials, such as

high - grade steel and durable alloys, which are carefully selected

for their strength, corrosion resistance, and longevity. Our

manufacturing process is also environmentally friendly, with strict

waste management and energy - saving measures in place.

Independent R&D and Inspection

We take great pride in our independent R & D capabilities. Our R &

D team is constantly exploring new technologies and materials to

improve the performance of our machines. They are engaged in

continuous research, attending international trade shows, and

collaborating with industry experts to stay at the forefront of

mechanical engineering.

Our in - house R & D efforts have led to several innovative

features in this basic series double - station machine. For

instance, we have developed a unique cooling system that ensures

the machine operates at optimal temperatures even during extended

periods of heavy use. This not only extends the lifespan of the

machine but also improves its performance and reduces the risk of

breakdowns.

In addition to R & D, our inspection process is equally rigorous.

Every machine undergoes a multi - stage inspection before it leaves

our factory. We start with component - level inspections, where

each part is carefully examined for any defects or deviations from

the design specifications. This is followed by sub - assembly

inspections, where we check the fit and function of pre - assembled

units. Finally, the fully assembled machine is put through a

comprehensive performance test.

We use a variety of inspection tools and techniques, including

precision measuring instruments, non - destructive testing methods

such as X - ray and ultrasonic testing, and functional testing on

simulated production lines. Our inspection team is staffed by

experienced quality control professionals who are dedicated to

ensuring that every machine meets our high - quality standards.

Customized Services for You

We understand that every customer has unique requirements. That's

why we offer customized services for those who need something

beyond the standard features of our basic series double - station

machine. Whether you have specific production needs, space

constraints, or integration requirements with your existing

manufacturing systems, our team is here to help.

Our customization process starts with a detailed consultation. We

work closely with you to understand your needs, goals, and any

challenges you may be facing. Our engineers then use this

information to develop a customized solution. This may involve

modifying the machine's design, adding or removing certain

features, or integrating it with other equipment.

For example, if you need the machine to handle a specific type of

material that has unique physical properties, our R & D team can

develop a specialized handling mechanism. Or, if you have limited

floor space in your factory, we can design a more compact version

of the machine without sacrificing its performance.

Once the customized design is approved, our manufacturing team goes

to work. They use the same high - quality manufacturing and

inspection processes as for our standard machines to ensure that

the customized product meets our strict quality standards. We also

provide comprehensive after - sales support for customized

machines, including training, maintenance, and spare parts supply.