SINO SDS2-3MS DRO Digital Readout System for Lathe and Milling

Machines with SDS3MS Display

SINO SDS2-3MS DRO Digital Readout System for Lathe and Milling

Machines with 3-Coordinate Numerical Display

The SDS2-3MS SINO Lathe and Milling Machine DRO Digital Readout

with SDS3MS Display is a sophisticated digital readout system

designed for lathe and milling machines. It offers precise,

real-time measurement feedback, enabling operators to monitor and

control the machining process with exceptional accuracy. This

system enhances operational efficiency and ensures consistent,

high-quality results.

Features:

The SDS3MS Display: This digital readout system is equipped with

the SDS3MS display, offering a clear and user-friendly interface

for monitoring machine measurements. The display unit is designed

with intuitive features, including easy-to-use function buttons and

a keypad, ensuring smooth and convenient operation for the user. It

provides quick access to critical machine data, enhancing workflow

and precision during machining tasks.

Multiple Axes: The SDS2-3MS DRO system supports multiple axes,

providing measurement feedback and control for various machine

movements. This feature allows for precise positioning and accurate

machining on different axes simultaneously, enhancing the

versatility and efficiency of the system. Whether you're working

with a lathe or milling machine, the multi-axis support ensures

that complex machining tasks can be handled with precision and

ease.

Lathe and Milling Compatibility: The SDS2-3MS DRO system is

designed to be compatible with both lathe and milling machines,

offering exceptional versatility for machinists. This flexibility

allows it to be seamlessly integrated into the control systems of

various machines, ensuring smooth and efficient operation. Whether

you're working with turning or milling processes, the system

provides accurate measurements and enhances overall machine

performance.

High Accuracy: The SDS2-3MS DRO system delivers high-precision

measurement readings, ensuring tight control over machine

movements. This level of accuracy is essential for achieving tight

tolerances and optimal results in machining operations. Whether

it's for fine adjustments or complex processes, the system's

precise feedback ensures that the final product meets the required

specifications with consistency and reliability.

Incremental and Absolute Modes: The SDS2-3MS DRO system offers both

incremental and absolute measurement modes, providing flexibility

for various machining tasks. In incremental mode, measurements are

taken relative to the previous position, which is ideal for making

repetitive adjustments or incremental changes. In absolute mode,

the system records the exact position of each axis from a fixed

reference point, making it perfect for precise, reference-based

measurements. Operators can easily switch between the two modes,

adapting to different machining needs for enhanced convenience and

accuracy.

Functionality:

The SDS2-3MS SINO Lathe Milling Machine DRO Digital Readout system

enables operators to monitor and control machine movements with

high precision during lathe and milling operations. By providing

real-time measurement feedback, it allows for immediate adjustments

and corrections, ensuring that machining processes stay on track.

This system enhances operational efficiency, helps achieve tight

tolerances, and supports the production of high-quality results by

offering precise, up-to-date data throughout the machining process.

Usage:

The DRO system is widely utilized in machining operations where

precise measurement and control are essential, including turning,

milling, drilling, and boring. Its versatility makes it applicable

across various industries such as metalworking, woodworking,

automotive, aerospace, and beyond. In these industries, the

SDS2-3MS DRO system helps ensure accuracy in complex machining

tasks, improves production efficiency, and maintains high-quality

standards by providing real-time, reliable feedback on machine

movements and positioning. This adaptability is key for meeting the

demanding requirements of different sectors.

Applicable Scenarios:

Lathe Operations: The SDS2-3MS DRO system is perfectly suited for a

variety of lathe operations, including facing, turning, tapering,

threading, and grooving. By offering precise measurement and

real-time feedback on tool movements, the system ensures that each

machining process is performed with high accuracy. Whether you're

working on creating a smooth surface, cutting threads, or shaping

complex geometries, the DRO system helps maintain tight tolerances

and consistent results, improving both the quality and efficiency

of lathe operations.

Milling Operations: The system is also well-suited for milling

operations, including contouring, slotting, drilling, and

profiling. It facilitates precise measurement and control of cutter

movements, allowing operators to achieve accurate and repeatable

milling operations.

DRO SDS3MS is a multipurpose gauge with a 3-coordinate numerical

display.

This gauge offers the flexibility to switch to the appropriate

function for different machine tools by simply adjusting the

parameters. This adaptability allows operators to easily customize

the system for various machining tasks, ensuring optimal

performance across a range of applications. Whether transitioning

between lathe, milling, or other machine tools, the ability to

adjust the parameters helps streamline operations, reduce setup

time, and improve overall machining efficiency. This feature makes

the system versatile and user-friendly for a wide array of

machining needs.

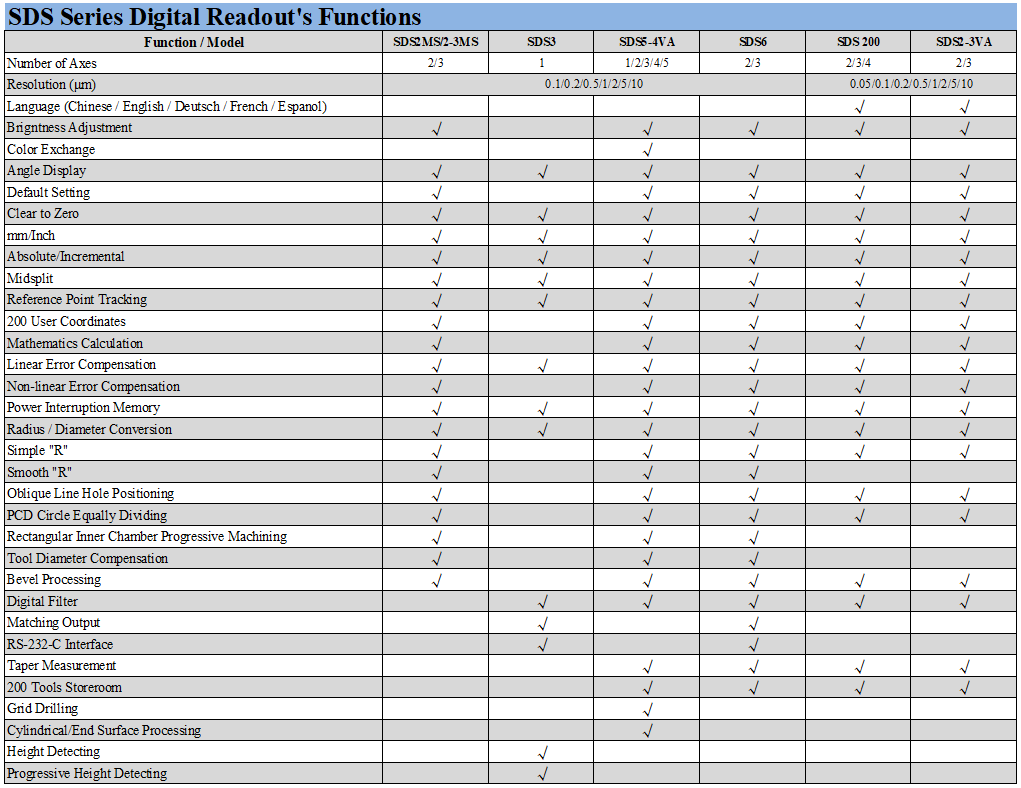

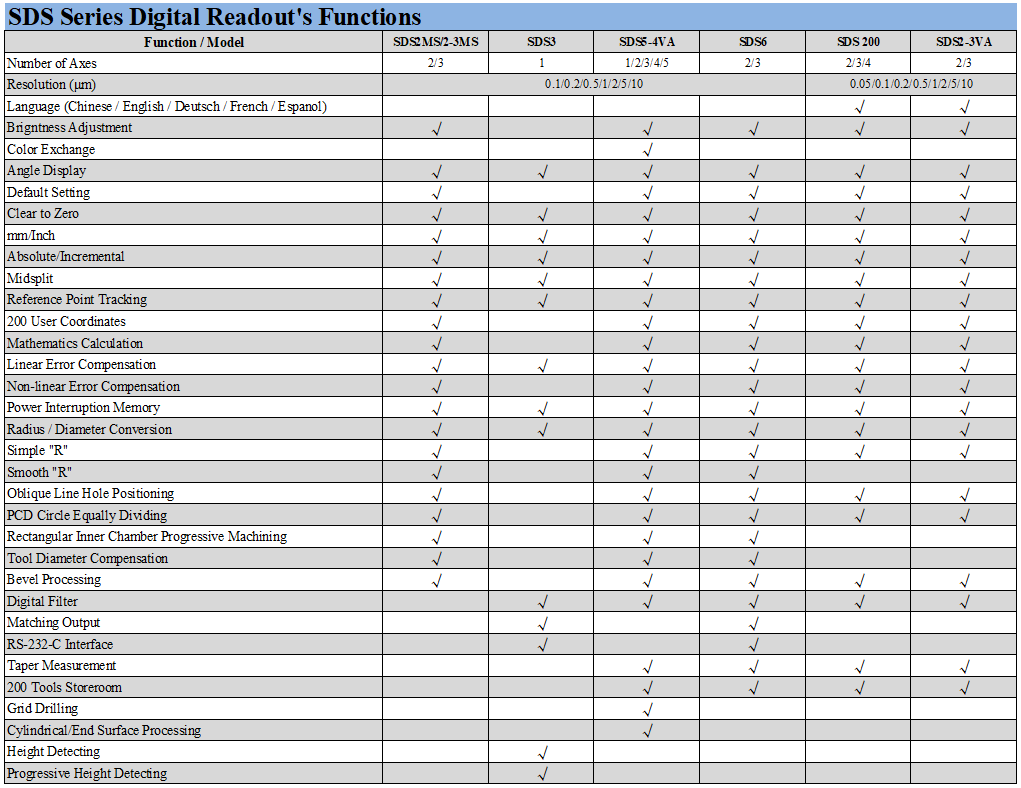

SINO SDS3MS digital readout parameters

- Voltage Range: AC 85V ~ 250V, 50Hz ~ 60Hz – This wide voltage range

allows the system to be compatible with various power sources,

making it adaptable to different regions or operational conditions.

- Power Consumption: 15W, with a maximum power of 25VA – The system

operates efficiently, ensuring minimal energy usage while still

providing high performance.

- Coordinate Number: The system supports 1-axis, 2-axis, or 3-axis

configurations, offering flexibility for different machining

setups.

- Display: The system features a 7-segment display that shows two or

three-axis output data. The display uses 8 digits and symbols to

present the measurements clearly, making it easy to track the

machine’s position.

- Weight: The unit weighs 2 kg, making it compact and manageable for

installation and setup.

- Input Signal: The system accepts TTL (Transistor-Transistor Logic)

and EIA-422 open collector output signals, which are convenient for

interfacing with programmable controllers and other industrial

automation systems.

- Input Signal Frequency: It supports an input signal frequency of

> 100kHz, ensuring high-speed data processing and accurate

real-time feedback.

- Resolution: The system allows for customizable resolution settings,

including 10 microns, 5 microns, 2 microns, 1 micron, and 0.5

microns, ensuring precision across various machining tasks.

Basic Functions

mm/inch Conversion | Absolute/Relative Conversion

Mid-split Function | Simple “R” Function

Smooth “R” Function | Divide the perimeter of a circle

Save 200 workpiece zero points | Divide holes along an angled line

Mathematical Calculation | Tool diameter compensation

Bevel Process | Automatic zero location reset

Packaging List :

| 1 PC | 3 Axis digital readout SDS3MS |

| 1 PC | Transparent cover |

| 1 PC | Instruction Manual (English) |

| 1 PC | Cable |

Product image /photos:

The rack in the picture is optioned, not standard product.