If you’re designing anything from aerospace components to sleek tech gadgets, custom aluminum CNC parts can be the game-changer you need. But what makes aluminum so special for CNC work? And how do you ensure your project gets the precision it deserves?

Why Aluminum?

Aluminum isn’t just popular because it’s light (though that’s a huge perk!). Here’s why engineers and designers love it:

- Machining Superstar: Cuts like butter compared to steel, saving time and tool wear. Less machine stress = tighter tolerances .

- Tough & Corrosion-Resistant: Naturally forms a protective oxide layer—no rust, even in harsh environments .

- Heat Dissipation Champ: Sucks heat away from electronics, making it ideal for heat sinks and enclosures .

- Eco-Friendly: 100% recyclable without losing quality—big win for sustainability .

How Custom Aluminum Machining Works

Wondering what happens after you send your CAD file? Here’s the behind-the-scenes magic:

1.Design & DFM (Design for Manufacturing):

- Engineers review your 3D model, flagging potential snags like thin walls or sharp corners.

- Pro tip: Reputable shops (like Weimai) offer free design analysis to optimize costs and feasibility .

2.Programming:

- CAM software converts designs into machine code. For complex shapes, 5-axis CNC is gold—milling at wild angles without re-fixturing .

3.Machining:

- Turning: Spinning the aluminum block while cutting tools shape it (perfect for cylinders, shafts).

- Milling: Rotating tools carve stationary metal (ideal for flat surfaces, slots).

- Speed matters: Up to 12,000 RPM spindle speeds ensure glass-smooth finishes .

4.Finishing Touches:

- Anodizing for color + scratch resistance.

- Sandblasting for matte textures.

5.Inspection:

- CMM machines verify tolerances down to ±0.005 mm .

Real-World Applications

- Aerospace: Wing brackets, landing gear—strength-to-weight ratio is non-negotiable .

- Auto: Engine blocks, brake calipers—cutting weight boosts fuel efficiency .

- Electronics: iPhone cases, server heatsinks—heat dissipation + sleek looks .

- Medical: Surgical tools—easy sterilization and precision .

| | CNC Turning, CNC Milling, Laser Cutting, Bending, Spining, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding,3D Printing,Rapid Prototype,Moulds etc. |

| | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

| Stainlesss steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. |

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper |

| Titanium: Grade F1-F5 |

| Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. |

| | Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

| | ±0.002 ~ ±0.005mm |

| | Min Ra 0.1~3.2 |

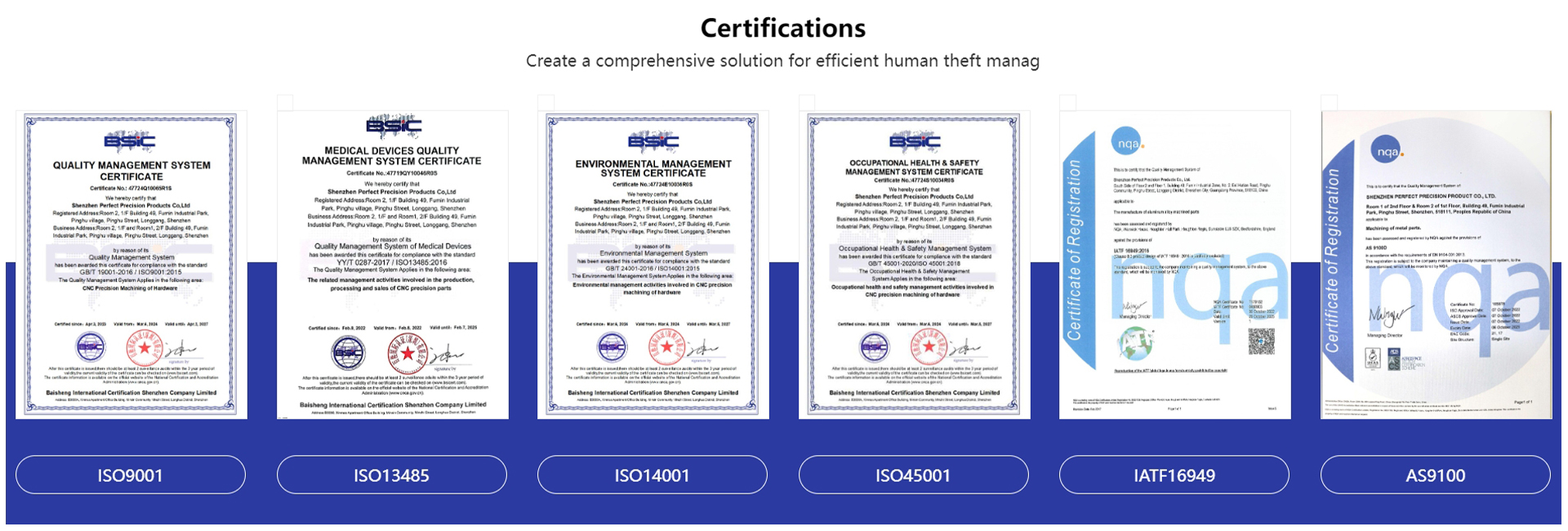

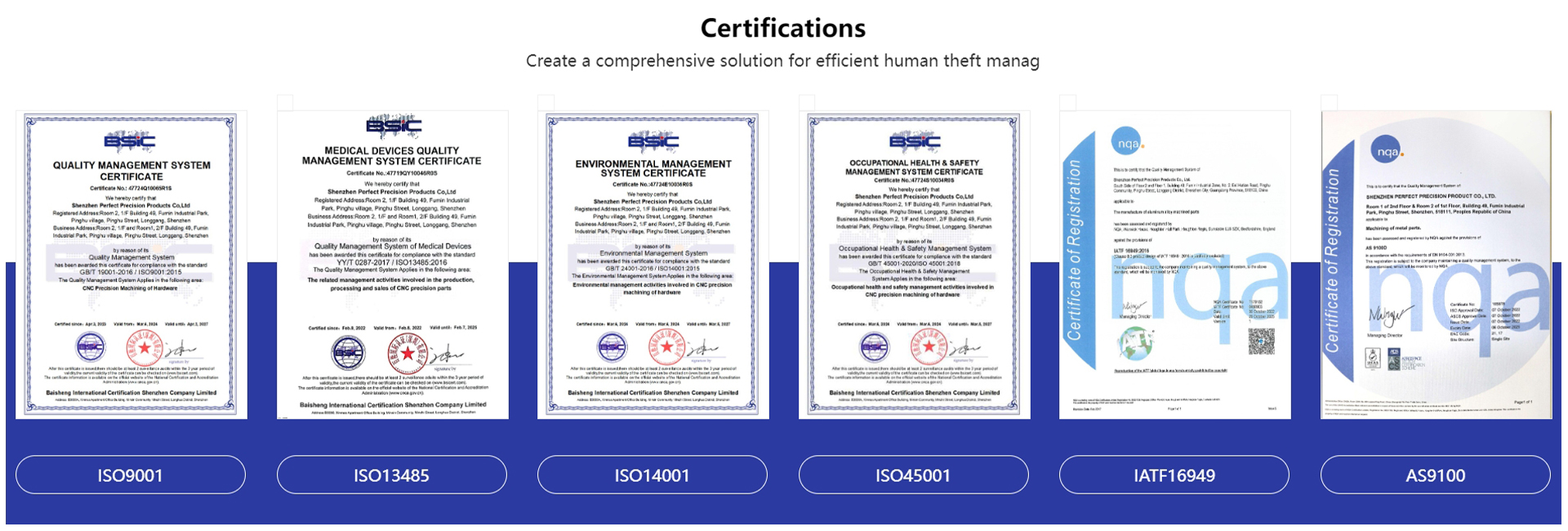

| CERTIFICATE | ISO9001:2015,AS9100D,ISO13485:2016,ISO45001:2018,IATF16949:2016,ISO14001:2015,ROSH,CE etc. |

FAQ

1. Are you a manufacturer or a trading company?

We are a factory located in Shenzhen, China, with 20 years of rich experience,

covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports.

2. How to get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information.

3. Can I get a quotation without drawings?

Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation.

4. Can you provide samples before mass production?

Of course, the sample fee is necessary. If possible, it will be returned during mass production.

5. What is the delivery date?

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks.

6. How do you control quality?

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure

critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment.

7. After sales service team

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.