| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | CNC Milling Parts |

|---|---|

| Brand Name: | PFT |

| Model Number: | OEM |

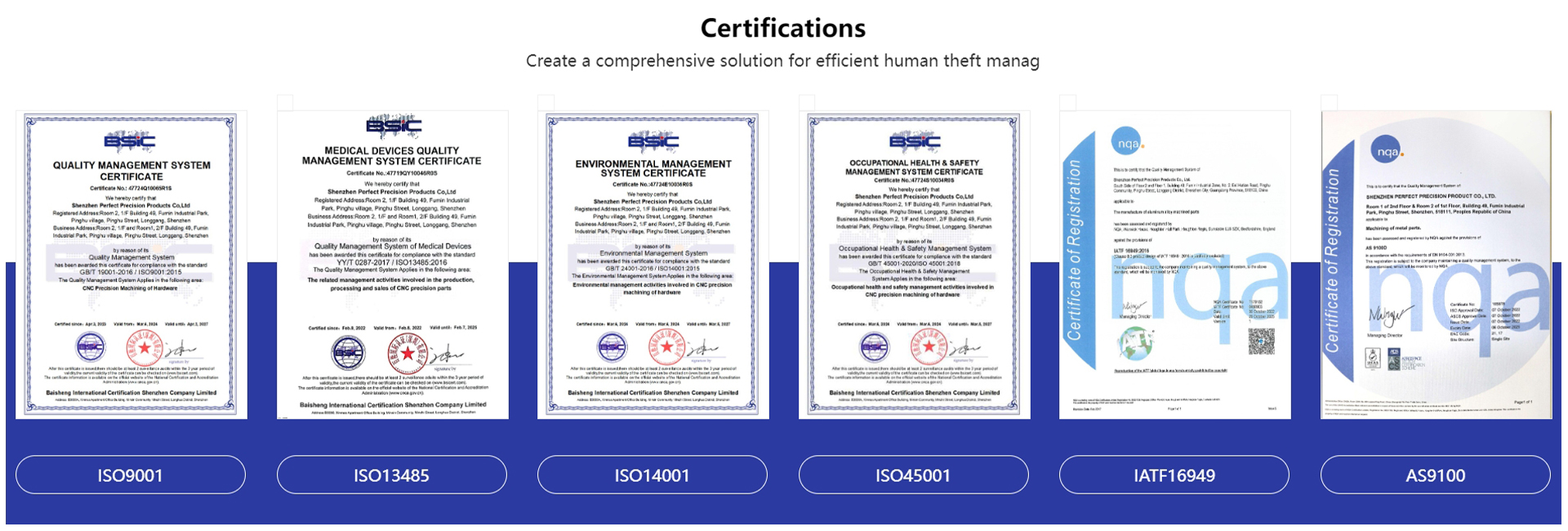

| Certification: | ISO9001:2015, ISO13485:2016 |

| Place of Origin: | Guangdong, China |

| MOQ: | 1PC |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 10000Pcs/ Month |

| Delivery Time: | 7-15 work days |

| Packaging Details: | As the requirement of customer |

| keyword: | CNC Milling Parts |

| Type: | Turn-mill Compound Parts |

| CNC Machining or Not: | CNC Machining |

| Material: | OEM Metal |

| Service: | Customized OEM |

| Company Info. |

| Shenzhen Perfect Precision Product Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

In the evolving world of modern manufacturing, precision, durability, and efficiency are critical. One of the most revolutionary techniques that has reshaped the production of complex components is 5-axis CNC machining. When this technology is combined with lightweight and corrosion-resistant materials like anodized aluminum, the result is high-performance components that meet the exacting standards of industries such as aerospace, automotive, medical, and electronics.

What is 5-Axis CNC Machining?

5-axis CNC (Computer Numerical Control) machining is an advanced manufacturing process that involves cutting tools moving across five different axes simultaneously. Unlike traditional 3-axis machines (X, Y, and Z), a 5-axis machine adds two rotary axes (A and B), allowing the cutting tool to approach the part from virtually any direction. This enables the production of highly complex geometries in a single setup, reducing errors, saving time, and enhancing surface finish quality.

Advantages of 5-Axis Machining for Aluminum Anodized Parts

Why Aluminum?

Aluminum is one of the most widely used materials in CNC machining due to its favorable mechanical properties:

The Role of Anodizing in Aluminum CNC Parts

Anodizing is an electrochemical process that enhances the natural oxide layer on the surface of aluminum. This treatment offers several benefits:

Anodized aluminum parts not only perform better under stress and environmental exposure but also look professional and high-tech, making them ideal for both functional and consumer-facing applications.

Applications of Aluminum Anodized 5-Axis CNC Machining Milling Parts

1.Aerospace Components

Precision is paramount in aerospace. 5-axis CNC machining allows for tight tolerances and complex shapes required for turbine blades, engine parts, and structural components, all while aluminum keeps the weight down.

2.Automotive Industry

From custom engine mounts to lightweight suspension parts, anodized aluminum CNC machined parts are used for performance, durability, and sleek design aesthetics.

3.Medical Devices

Complex surgical instruments and diagnostic equipment benefit from the precision and biocompatibility of anodized aluminum components.

4.Consumer Electronics

Housings, heat sinks, and structural frames are commonly made from anodized aluminum due to its conductivity and modern appearance.

5.Robotics and Automation

Lightweight, durable, and customizable parts make aluminum anodized 5-axis CNC machined components ideal for robotic arms, joints, and enclosures.

1. Are you a manufacturer or a trading company?

|