| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Punch Mold Components |

|---|---|

| Brand Name: | Kinyet |

| Model Number: | Anti-abrasive Carbide Dies |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 1pcs |

| Price: | Negotiable |

| Payment Terms: | T/T etc |

| Supply Ability: | 10*1000pcs/month |

| Delivery Time: | 3 or more work days |

| Packaging Details: | 1. We will choose the right package according to the shape of the product. Usually choose foam plastic, cartons, large cartons, professional plastic packaging boxes and so on. 2. According to your choice or our recommendation of the best transportation pla |

| Customized Support: | OEM,ODM |

| Product Type: | Punch Mold Components |

| Material: | tungsten carbide,ceramic etc. |

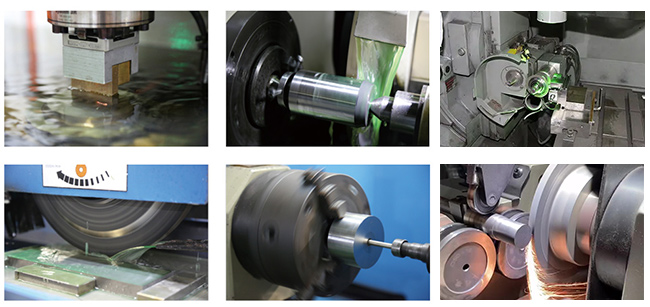

| Involve Technology: | Cylindrical grinding, PG, wire-electrode cutting, etc |

| Surface Treatments: | blank,ground,polished or per your requirement |

| Specification: | Customized |

| Coating: | To be defined per your demands |

| Accuracy: | ±0.001mm |

| Surface Roughness: | RZ~~0.2um / F1.0mm/min |

| Advantages: | High wear resistance,quick delivery and stable quality |

| Sample order: | Acceptable |

| Usage: | Used for mechanical wear-resistant parts |

| Company Info. |

| Dongguan Drow Precision Alloy Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Customized Punch Mold Components for Mechanical Wear-Resistant Parts Anti-Abrasive

Mechanical wear-resistant parts include seals, wear-resistant sheets, anti-corrosion pads, wear-resistant pads, grinding rods, rolls, and other accessories. Depending on the specific mechanical components and user applications, various cemented carbide materials are selected for production. This approach effectively extends tool life and reduces the frequency of component replacements.

Chemical machinery parts, such as nozzles and anti-corrosion gaskets, can be manufactured from different materials tailored to specific mechanical components and user applications. Typically, cemented carbide and HSS materials are utilized to significantly prolong the service life of machinery and reduce customer costs.

| Material | Material Properties |

|---|---|

| Carbide | Cemented carbide is a powder metallurgical composite consisting of one or more hard material phases (e.g., tungsten carbide) and a binding material (e.g., cobalt). It is extremely hard, characterized by high wear resistance and thermal stability, making it suitable for applications that require particularly wear-resistant tools or components. While it is more challenging to machine and has a higher material cost compared to die steel, its service life is often several times longer. |

| Ceramic | Ceramic materials exhibit excellent high-temperature resistance and are crucial for applications operating continuously at temperatures ranging from 180 °C to over 1200 °C. Compared to metallic materials, oxide ceramics show significant resistance to chemical attack, particularly in acidic and alkaline environments. Common types include alumina, zirconia, silicon carbide, and silicon nitride ceramics. |

| HSS | High-speed steel (HSS) offers superior abrasion resistance and toughness for general applications. It is primarily used in small batch production or in fields that require high material toughness. |

Involve Machining Technology:

Kinyet is dedicated to the research and development of tungsten-related materials. By continuously introducing new technologies and increasing investments in high-end production equipment, Kinyet provides mold solutions with an exceptional quality-to-price ratio, featuring high precision, longer tooling life, and cost-effectiveness. We are excited to announce our merger with Drow; together, we believe we will create even better products for consumers in the future!

Q1: Do you produce special punch molds or punch die components?

A: Yes, we specialize in customized mold fabrication and can

translate the most complex punch die concepts into reality. Our

punch mold components are designed and tailored for various

demanding applications and materials.

Q2: Do you accept low volume for sample orders? What’s your MOQ for

customization?

A: Yes, we do. For sample orders, we accept a minimum order

quantity (MOQ) of one piece. Please attach CAD or 3D drawings with

your inquiry. The sample lead time is 10–15 days, and it can be

negotiated for other special requirements.

Q3: If we want to cooperate with you, is confidentiality

guaranteed?

A: Absolutely. All your information, including company details,

drawings, and purchase order specifics, will be kept confidential.

We can sign an NDA (Non-Disclosure Agreement) if you wish.

Q4: What are your payment terms?

A: We require a T/T payment structure of 30% as a deposit and 70%

balance before delivery. We will provide photos of the products and

packaging before you pay the balance.

Q5: What products can you buy from us?

A: We offer carbide inserts, carbide end mills, carbide drills,

carbide boring tools, cutting tools, and customized carbide

precision molds.

Q6: Can you send products to our forwarder in China?

A: Yes, if you have a forwarder in China, we would be glad to send

the products to them.

Q7: What about the packaging?

A: We use plastic boxes to pack our products, with shockproof

filling material, and transport them in cartons. We can also

customize the packaging according to your needs based on the shapes

of the products.

Q8: Does your company accept customization?

A: Yes, both OEM and ODM services are available. We have a

professional R&D team dedicated to serving your needs.

|