| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Vacuum Conveyor Systems |

|---|---|

| Brand Name: | EVERSUN |

| Model Number: | QVC |

| Certification: | ISO,CE |

| Place of Origin: | CHINA |

| MOQ: | 1set |

| Price: | negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, MoneyGram, Western Union |

| Supply Ability: | 5000set/year |

| Delivery Time: | within 7-15 work days |

| Packaging Details: | Standard export wooden cases |

| Quality: | GMP Standard, ISO and CE certified |

| Material: | Stainless Steel |

| Air Pressure: | 0.4~0.6 MPA |

| Customized Service: | Provided |

| Application: | Food, Pharmaceutical, Chemical, Packaging |

| Conveying Capacity: | 100kg/h |

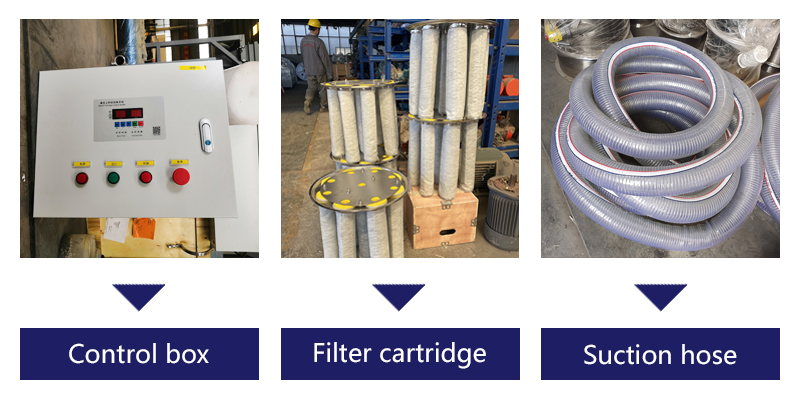

| Control: | PLC Control/Control Box |

| Conveyor Speed: | Adjustable |

| Temperature: | Normal Temperature |

| Product Type: | Conveyor Systems |

| Structure: | Closed |

| Usage: | Conveying powder ,granules |

| Company Info. |

| EVERSUN Machinery (Henan) Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

![]()

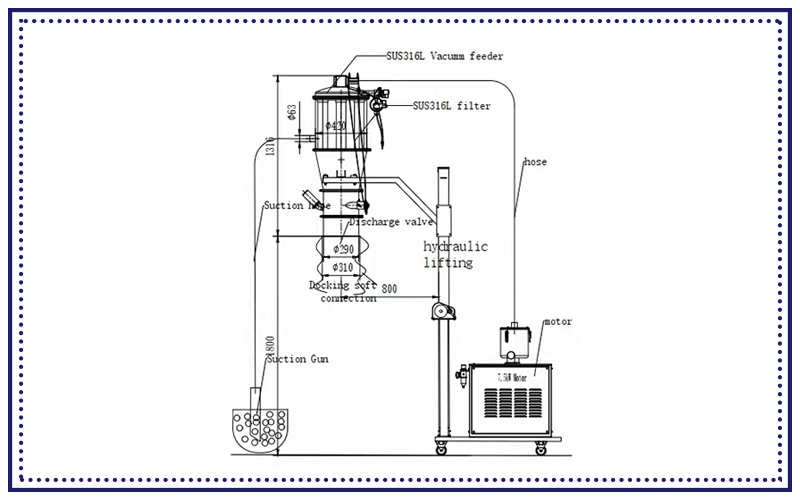

Vacuum feeder, also known as vacuum conveyor, is a kind of dust-free and sealed

pipeline conveying equipment that uses vacuum suction to convey granular anddery

materials. It uses the pressure difference between vacuum and ambient space to

form gas flow in the pipeline, which drives the movement of powdery materials, thus

the conveying of powders.

![]()

A vacuum pump is used to produce negative pressure, which keeps the suction

nozzle inlet and the entire conveying system at a certain vacuum state, creating

pressure difference with the external environment. Under the action of the pressure

difference, powdery materials are sucked into the nozzle along with the external air,

forming a material stream, which is then transported to the hopper of the feeder

through the suction pipe. After entering the hopper, the materials are separated from

the air, and air is discharged from the system through the filter, while the materials

fall freely due to gravity. When the materials in the silo reach a certain amount or

meet the conditions, the discharge valve opens, and the materials are discharged,

and the cycle repeats.

![]()

1. Environmental protection and hygiene: The enclosed conveying method effectively

avoids dust and pollution during the conveying process, protecting the production

environment and the of workers.

2. Efficient and energy-saving: It can achieve continuous and automatic material

conveying, greatly reducing the need for manual operation and improving the overall

efficiency of the line, with relatively low energy consumption.

3. Precise control: Equipped with advanced sensors and control systems, it can monitor

the status of material conveying in real and make fine adjustments according to actual

needs, ensuring the accuracy and reliability of the conveying.

4. Strong adaptability: It can handle a variety of materials with different, shapes, and

particle sizes, such as powders and granules, meeting the production needs of different

industries and products.

5. Space-saving: The pipeline conveying occupies less space and can complete the

conveying of powdery materials in narrow spaces, making the workspace look neat and

spacious.

| Model | Hopper Capacity(L) | Working pressure | Conveying Capacity(kg/h) | Compressed air consumption |

| QVC-1 | 1.1 | 0.4-0.6Mpa | 50-300 | 180NL/min |

| QVC-2 | 6 | 0.4-0.6Mpa | 100-700 | 360NL/min |

| QVC-3 | 12 | 0.4-0.6Mpa | 300-1500 | 720NL/min |

| QVC-4 | 42 | 0.4-0.6Mpa | 600-3000 | 1440NL/min |

| QVC-5 | 60 | 0.4-0.6Mpa | 900-6000 | 2880NL/min |

![]()

![]()

![]()

Wide range of applications: The vacuum loader is mainly used for conveying

powdery and granular materials, such as raw pharmaceutical powders,

chemicalders, metal oxide powders, etc.; however, it is not suitable for conveying

overly moist, sticky, or heavy materials.

![]()

![]()

![]()

We have been specializing in the production of Screening and conveying equipment for

13 years. China's vibrating screen industry top three. And we have done matching and

OEM for many large companies. Including the world's top vibrating screen manufacturer,

Sweco, USA, we have OEM for his China region. And our products are often exported to

Australia, Thailand, Indonesia, New Zealand and other countries.

We welcome customers or dealers to visit our factory and will

arrange everything for you.

Our factory address: West of the industrial and commercial office

of Da Zhaoying Town,

Xinxiang City, Henan Province.

|