| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Rubber Calender Machine |

|---|---|

| Brand Name: | Beishun |

| Model Number: | XYB-1500 |

| Certification: | ISO/CE/SGS |

| Place of Origin: | Qingdao,China |

| MOQ: | 1set |

| Price: | Negotiable |

| Payment Terms: | T/T,L/C |

| Supply Ability: | 30sets/month |

| Delivery Time: | 40day |

| Packaging Details: | Wooden box/container |

| Max. Calendering Width: | 1500mm |

| Max. Calendering Thickness: | 10mm |

| Heating Method: | Steam/Oil/Electric |

| Application: | rubber sheet, plate |

| Control Type: | PLC |

| Safety: | Emmergency Botton/Safte Rope/Foot Brake |

| Roller Width: | 500-2000mm |

| Bush Type: | Bearing |

| Roller Length: | 1000mm |

| Roller Size: | 300×900mm |

| Marketing Type: | New Product 2020 |

| Converter: | ABB |

| Roll Material: | Chilled Cast Iron |

| Roller Speed: | Adjustable |

| Customized Services: | Support Customization |

| Company Info. |

| Qingdao Beishun Environmental Protection Technology Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

ODM Or OEM 2, 3, 4 Roller Rubber Calender With High Quality And

Fast Delivery

Differences between Two-roller calender and Three-roller calender

I. Roller structure and material transmission method

Two-roller calender

The structure of the two-roller calender is relatively simple,

mainly composed of two rollers rotating in opposite directions. The

rubber material is sent to the gap between the two rollers through

the feeding device. Material transmission mainly relies on the

friction between the two roller surfaces and the rubber material.

For example, when the rubber material contacts the rotating roller,

it is rolled into the gap between the rollers under the action of

friction and transported forward as the rollers rotate. This

transmission method is relatively direct and is suitable for some

simple calendering operations that do not require particularly high

thickness accuracy and have a relatively regular shape of the

rubber material.

Three-roller calender

The three-roller calender has an upper roller, a middle roller and

a lower roller. Its material transmission process is more

complicated. The rubber material can enter between the rollers from

two positions. A common method is that the rubber material first

enters between the upper roller and the middle roller, and then

passes between the middle roller and the lower roller before being

output. In this process, the rubber material is initially

calendered and transmitted between the upper roller and the middle

roller, and then further calendered and adjusted in shape between

the middle roller and the lower roller. Due to the synergistic

effect of three rollers, the three-roll calender can better control

the flow direction and shape of the rubber material, making the

rubber material more evenly distributed during the calendering

process.

II, Calendering effect and product quality

Two-roll calender

The calendering of the rubber material by the two-roll calender is

mainly a one-time extrusion process. Because there are only two

rollers, the rubber material is calendered after passing through

the gap between the rollers. This method is relatively difficult to

achieve high precision in thickness control. For example, if you

want to produce thin sheet rubber products with very uniform

thickness, the two-roll calender may cause a certain deviation in

thickness due to the uneven flow of the rubber material in the gap

between the rollers. However, for some rubber products that do not

have strict thickness requirements, such as some rough rubber pads,

the two-roll calender can meet the basic calendering needs.

Three-roll calender

The three-roll calender can more effectively control the thickness

and surface quality of the product through two calendering

processes. The first calendering between the upper roller and the

middle roller can preliminarily adjust the thickness and shape of

the rubber material, and the second calendering between the middle

roller and the lower roller can further refine it. This makes the

rubber products produced more uniform in thickness and smoother in

surface. For example, when producing the cover layer of

high-quality rubber conveyor belts, the three-roll calender can

better ensure the uniformity of thickness and surface flatness of

the cover layer, thereby improving the quality and service life of

the conveyor belt.

III. Adaptability to rubber and processing range

Two-roll calender

Due to its simple structure, the two-roll calender has certain

limitations in its adaptability to rubber. It is more suitable for

processing some rubbers with relatively low viscosity and

relatively soft texture. Because for rubbers with high viscosity or

complex ingredients such as more fillers, the two-roll calender may

not be able to effectively make the rubber pass through the roller

gap evenly, and it is easy to cause rubber accumulation or uneven

calendering. In terms of processing range, the two-roll calender is

mainly used for some simple rubber sheet calendering, preliminary

mixing of rubber and simple laminating operations.

Three-roll calender

The three-roll calender has a stronger adaptability to rubber. It

can process rubbers of various viscosities and complex ingredients.

Due to its special structure with three rollers, it can better cope

with the complex rheological behavior of rubber during calendering.

For example, for rubber containing fiber-reinforced materials, the

three-roll calender can better distribute the fibers in the rubber

while ensuring the calendering quality of the rubber. In terms of

processing range, in addition to being able to produce high-quality

rubber sheets, the three-roll calender is also widely used in the

lamination of materials such as rubber and fabric, rubber and steel

wire, and the production of parts for complex rubber products such

as tires and conveyor belts.

Working principle and characteristics of calender:

Working principle

Roller arrangement and material entry

Common roller arrangements for 4-roll calenders include L-type and

Z-type. Taking the L-type as an example, the rubber material is

first fed to the gap between the first and second rollers by the

feeding device. The rollers rotate synchronously and in opposite

directions, and the rubber material is rolled into the gap under

the friction of the rollers. This process is similar to the initial

feeding principle of the double-roll and three-roll calenders.

Multiple calendering processes

After passing through the gap between the first pair of rollers,

the rubber material is initially calendered and changes its shape.

Then, it enters between the second pair of rollers for further

calendering. For example, in an L-type 4-roll calender, after the

rubber material comes out of the first and second rollers, it will

enter between the second and third rollers or between the third and

fourth rollers (depending on the specific process requirements).

Each calendering will further reduce the thickness of the rubber

material, further expand the width, and make the molecular chains

inside the rubber material more orderly.

Working with auxiliary devices

The 4-roll calender is also equipped with auxiliary equipment such

as feeding devices, traction devices and temperature control

systems. The feeding device ensures that the rubber enters the gap

between the rollers evenly and stably, and the traction device

pulls out the calendered material at an appropriate speed to

prevent material accumulation or over-stretching. The temperature

control system changes the fluidity of the rubber by adjusting the

roller temperature, so that the rubber can better adapt to

different process requirements during multiple calendering

processes and ensure product quality.

Features

High-precision product thickness control

Due to the four rollers squeezing and shaping the rubber, the

4-roll calender can produce rubber products with very high

thickness accuracy. Compared with the double-roll and three-roll

calenders, it can more accurately calender the rubber to a very

thin thickness and maintain uniform thickness. For example, in the

production of some high-precision rubber films for electronic

equipment sealing and other fields, the advantages of the 4-roll

calender are very obvious, and the thickness error of the rubber

film can be controlled within a very small range.

Good product quality and surface finish

After multiple calendering, the internal structure of the rubber is

more uniform and the surface is smoother. The rubber products

produced by the 4-roll calender have a high level of surface

quality and can reduce surface defects such as wrinkles and

bubbles. This is very important for the production of high-quality

rubber conveyor belts, rubber seals and other products with high

surface quality requirements. For example, when manufacturing the

airtight layer of high-end automobile tires, the 4-roll calender

can ensure that the surface of the airtight layer is flat and

smooth, thereby improving the overall quality of the tire.

Complex process adaptability and versatility

The 4-roll calender can adapt to a variety of complex processes. It

can not only be used for simple rubber compound calendering, but

also for composite calendering of rubber and multiple materials.

For example, when producing rubber-fabric-rubber multi-layer

structure products (such as waterproof membranes), the 4-roll

calender can well fit the rubber and fabric tightly while ensuring

the thickness and quality of each layer. Moreover, by adjusting the

parameters such as roller speed, temperature and gap, different

calendering processes can be achieved to produce rubber products

with different shapes, thicknesses and performance requirements.

High production efficiency

Although the 4-roll calender has a complex structure, it can

complete multiple calendering steps in one process, reducing the

time of repeated processing. Its production efficiency is

relatively high when mass-producing high-precision and high-quality

rubber products. For example, when producing large rubber sheets

for industrial shock absorption and other purposes, the 4-roll

calender can quickly calender the rubber into the required sheets

and ensure that the quality of the sheets meets the requirements.

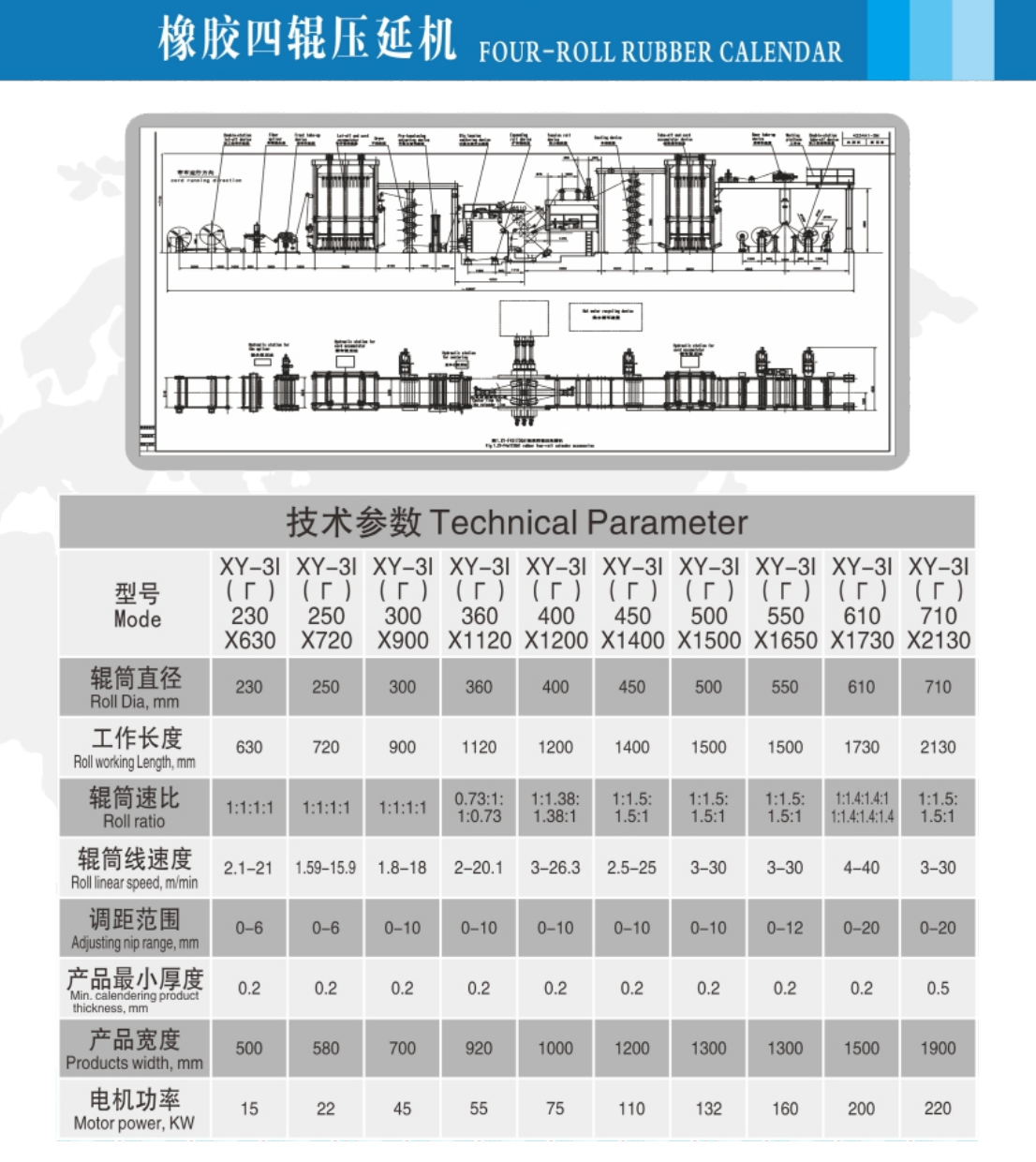

Technical Parameters:

|