| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

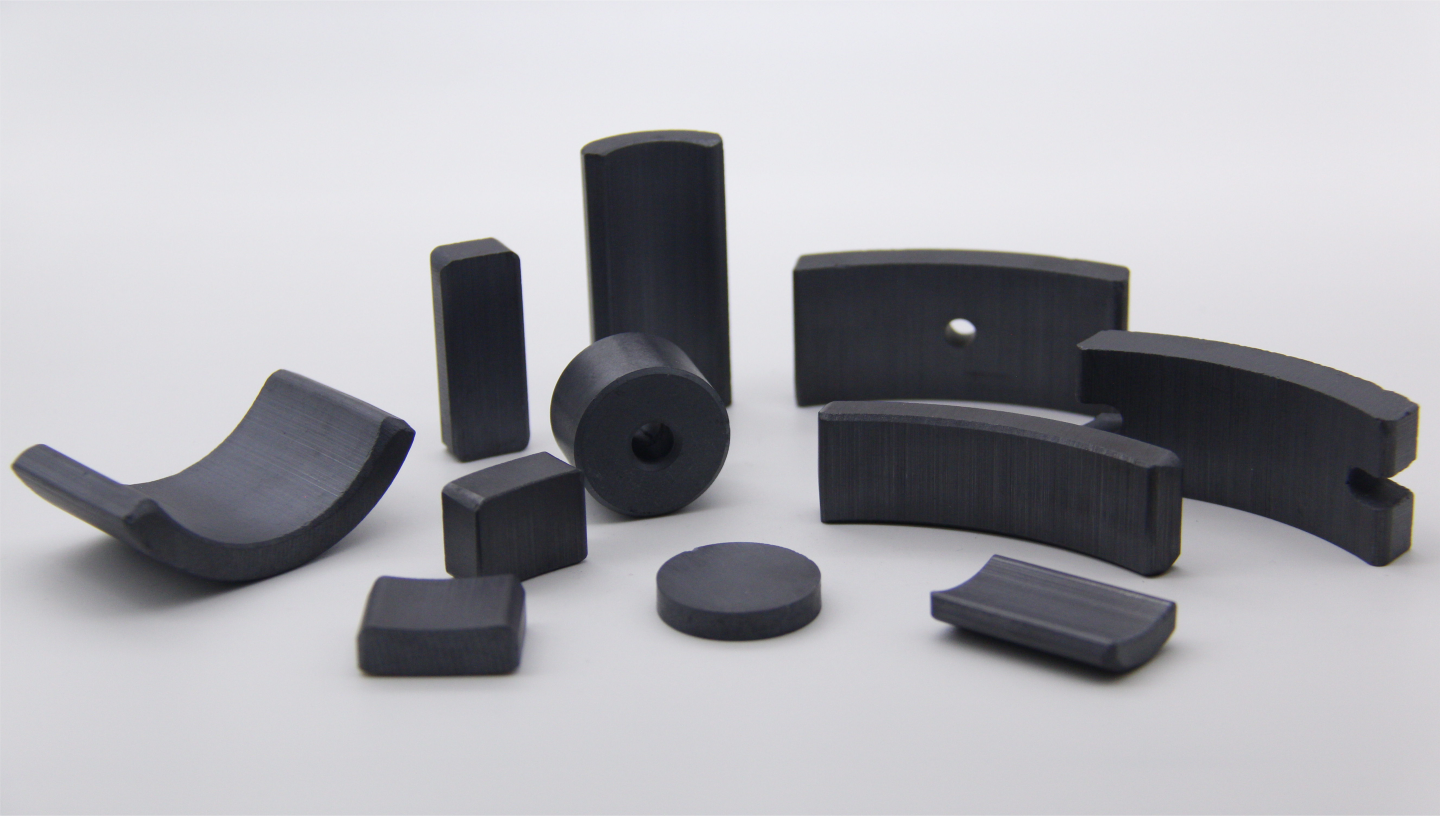

| Categories | Permanent Ferrite Magnet |

|---|---|

| Brand Name: | XINHENG |

| Model Number: | W123 |

| Certification: | IATF16949,ISO9001 |

| Place of Origin: | Sichuan, China |

| MOQ: | 1000pcs |

| Price: | Negotiation |

| Payment Terms: | T/T, L/C, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 10000 ton per year |

| Delivery Time: | 10-15days |

| Packaging Details: | Carton+pallet |

| Product name: | Permanent Magnet Ferrite |

| Application: | Inverter motor |

| Shape: | Arc,Tile |

| Type: | Anisotropic sintered magnet |

| Composite: | Ferrite strontium powder |

| Size: | (R83.0mm-r73.25mm)×31.0mm |

| Processing: | Wet Pressed |

| Coating: | No Coating |

| Package size: | 340mm×255mm×75mm |

| Quantity per carton: | 840pcs |

| Company Info. |

| Sichuan Xinheng Magnetic Materials Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

High Coercivity Permanent Magnet Ferrite Sintered At High

Temperaturefor Inverter Motor W123

Home version of the weeder working principle:

Mowers are usually powered by an internal combustion engine or an

electric motor. Electric motors are generally used for small

mowers, while internal combustion engines are mostly used for large

or professional grade equipment.

Blade: The core component of a weeder is the blade, usually made of

metal and with a sharp edge. The rotation or reciprocating motion

of the blade can effectively cut weeds.

Drive system: Power is transferred to the blade through the drive

system, causing it to rotate or reciprocate to perform the cutting

action.

Height adjustment device: Most weeders come with adjustable height

Settings to adjust the cutting height for different types of lawn

and weeds.

After starting the weeder, the power source drives the blade to

start rotating or moving.

The cutting action of the blade will cut the weed, and after the

weed is cut, it may be blown to the side or collected in a grass

collection bag (depending on the design of the weed remover).

The operator can control the speed and cutting height of the weeder

according to the need to achieve the ideal weeding effect.

Company profile

The company boasts the first domestically developed servo

fully-automatic wet press oil press machine and the first

dual-track roller kiln in the nation. It also possesses the

capability for independent design, development, and processing of

various types of molds.

The primary business of the company focuses on sintered ferrite

permanent magnet components, encompassing automotive motors,

motorcycle motors, general machinery motors, household appliance

motors, household fan motors, variable frequency motors, water pump

motors, and more. These products are widely used in the automotive,

motorcycle, office equipment, power tools, household appliances,

and fitness equipment industries.

What is permanent magnet ferrite?

Permanent magnet ferrite has a very high magnetic energy product

and coercivity, it can produce a large magnetic field and magnetic

force under a small size and weight, while having a high magnetic

temperature coefficient and thermal stability, can maintain stable

magnetic properties at higher temperatures. This makes the

permanent magnet ferrite still able to work normally in a high

temperature environment and is not easy to lose magnetism. Good

corrosion resistance and wear resistance, so that it is not easily

affected by the external environment and damage.

What's the application of Xinheng's permanent ferrite magnets?

Xinheng mainly manufactures the following types of ceramic arc

segment magnets:

PHYSICAL PROPERTIES OF SINTERED FERRITE MAGNETS

| Units | Sintered Ferrite (Ceramic) | |

| Curie Temperature | ºC | 450 |

| Maximum Operating Temperature | ºC | 350 |

| Hardness | Hv | >530 |

| Density | g/cm3 | 4.8 – 5.0 |

| Relative recoil permeability | μrec | 1.05-1.1 |

| Temperature Coefficient Br | %/ºC | -0.18 |

| Temperature Coefficient iHc | %/ºC | 0.11-0.40 |

| Anti-Bending Strength | N/m2 | (0.5-0.9)×108 |

| Anti-Compressive Strength | N/m2 | ≥6.9×108 |

| Anti-Tensile Strength | N/m2 | (0.2-0.5)×108 |

| Specific Heat | J/kg·K | 600-900 |

| Resistivity | Q.cm | >104 |

What's the feature of ceramic strontium ferrite magnet made by wet

compression molding?

FERRITE POWDER GRADE OF UNIVERSAL MOTORS MAGNET

| Grade | Br(mT) | Hcb(KA/m) | Hcj(KA/m) | (BH)max(KJ/m3) | ||||

| mT | Gs | KA/m | Oe | KA/m | Oe | KJ/m3 | MGOe | |

| Y30H-1 | 380-400 | 3800-4000 | 230-275 | 2890-3460 | 235-290 | 2950-3640 | 27.0-32.5 | 3.4-4.1 |

| Y33 | 410-430 | 4100-4300 | 220-250 | 2760-3140 | 225-255 | 2830-3200 | 31.5-35.0 | 3.9-4.4 |

| Y33H | 410-430 | 4100-4300 | 250-270 | 3140-3390 | 250-275 | 3140-3450 | 31.5-35.0 | 3.9-4.4 |

| Y35 | 430-450 | 4300-4500 | 215-239 | 2700-3000 | 217-241 | 2730-3030 | 33.1-38.2 | 4.1-4.8 |

|