| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | PET Bottle Washing Line |

|---|---|

| Brand Name: | PR or Pulier |

| Model Number: | QXL6500 |

| Certification: | CE, SGS, UL |

| Place of Origin: | CHINA |

| MOQ: | 1 SET |

| Price: | USD100000 |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 20 lines per year |

| Delivery Time: | 60 to 80days |

| Packaging Details: | Shipment Requested |

| Name: | Paper Label Remover |

| Material Processed: | Plastic Bottle |

| Plastic Type: | PET |

| Screw: | Single Screw |

| Automation: | Automatic |

| Computerized: | Computerzied |

| Capacity: | 6500kghr |

| Machine component: | Plastic Sorting, Crushing, Washing and Drying |

| Motor: | WNM, ABB, WEG, DAZHONG, CHINA Famous Brand |

| Control Inverter: | Frequency Control |

| Gear Box: | Changzhou Guomao or Customerized |

| Material: | Stainless steel or carbon steel |

| Wall thickness: | 3mm to 20mm |

| Color: | white and green, yellow and blue |

| Warranty time: | 13 months |

| Aboard service: | installation and commision |

| HS CODE: | 84778000 |

| Company Info. |

| Chengdu Purui Polymer Engineering Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

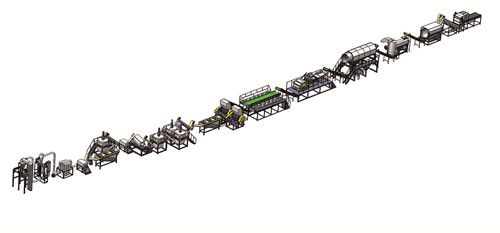

Zigzag Paper Label Remover

PET bottle washing line /PET bottle recycling plant/PET recycling process

PR Recycling Machine (Label Separating, Crushing, Washing, Drying and Granulating)

HDPE/PP/PET Bottle Recycle Washing Machines are special designed for PET bottle, HDPE milk bottle, PP /PE Bottle, HDPE blue jar, oil

bottle, Jerry Can, Waste Plastic Container, Plastic Bucket, Plastic

Hollow Bottle with sand, stone, powder, oil and other sticky waste.

Capacity range: 500kg/h to 6500kg/h

PR Recycling Machine Information

Plastic bottle label separating, cutting, washing, recycling machine with high output and excellent

clean ability

Whole plastic recycling line is used to crush, wash, dewater and

dry the PP/PE flake or rigid material

Simple structure, easy operation, large capacity, energy-saving,

safety

Automatic controlling, compacted structure, excellent production

ability, perfect clean ability

| No | Name | Function |

| 1 | Debale | To debale the |

| 2 | Twin spiral charger | Label sorting, intelligent sorting, manual sorting |

| 3 | Rotary screen | |

| 4 | Belt conveyor | |

| 5 | Dewatering | |

| 6 | Pre-washing | |

| 7 | Intelligent optical sorting system | |

| 8 | Manual sorting system | |

| 9 | Crushing | To crush the PET bottle into flake |

| 10 | Spiral feeder | Washing process |

| 11 | Floating tank | |

| 12 | Hot washer | |

| 13 | High speed friction washer | |

| 14 | Dewatering machine | |

| 15 | Round floating washing | |

| 16 | Floating tank | |

| 17 | dewatering | PET bottle flake drying process |

| 18 | Pipe drying | |

| 19 | Bottle label separator | To further remove the PE,PP label |

| 20 | Compacting packing |

Final PET flake quality reference

| Moisture content | <0.9% | Label | <19ppm |

| PVC | <49ppm | Variegated tablets | <28ppm |

| glue | <10.5ppm | PH | (neutral) |

| PP/PE | <19ppm | Total impurity | <100ppm |

| Metal | <18ppm | Flake size | 12mm,14mm(customization) |

| Capacity(kg/hr) | Power installed (kW) | Warehouse are( m2) | Manpower | Water supply (m3/h) |

| 500 | 116 | 1500 | 4 | 5 |

| 1000 | 200 | 1800 | 5 | 6 |

| 2000 | 406 | 2000 | 5 | 8 |

| 3000 | 500 | 2500 | 6 | 10 |

Output PET flake quality reference

| Moisture content | <0.9% | Label | <19ppm |

| PVC | <49ppm | Variegated tablets | <28ppm |

| glue | <10.5ppm | PH | (neutral) |

| PP/PE | <19ppm | Total impurity | <100ppm |

| Metal | <18ppm | Flake size | 12mm,14mm(customization) |

While PVC labels can directly decompose PET during subsequent thermal processing,and the IV viscosity of PET bottle flakes will be reduced to the point where it cannot be recycled.

The material contact parts of the separation and cleaning equipment

for PET bottle flakes,labels and bottle caps are made of stainless

steel,which will not rust or contaminate the separated materials.In

the sealed separation box,the bottle flakes,labels and bottle caps

fall at the same time.

At the same time,a suction fan is used to extract air from the side to form a negative pressure,and the amount of negative pressure is adjusted through the air volume regulating valve,so that the heavier botte flakes per unit volume are It just falls into the unloading port,and the lighter weight labels and bottle caps can be extracted and entered into the label and bottle cap collection bag, thereby achieving the purpose of separating labels from bottle flakes and bottle caps.

The interface between the cyclone blanking tank and the separation boxisdesigned like a"three-way"structure.Label and bottle cap collection bags use cloth bags of certain specifications,which have dust removal effects

With the polyvinyl chloride(PVC),polyethylene(PE),polypropylene(referred to as PP)or paper material affixed to the bottle body,and PE cover,to ensure the purity and quality is quite important during bottle recycling process.

PET bottle flakes must be separated from the label and bottle cap.

During floating washing process,some labels and bottles with a

specific gravity smaller than water are The cap floats on the

water,while the bottle flakes with a specific gravity greater than

water will sink into the water,so that the PET bottle flakes,labels

and bottle caps can be separated from each other.

Key Features

High Automation:

Reduces labor costs significantly, especially beneficial for

operations running three shifts.

Processing capacity ranges from 500 to 6500 kg/hr.

User-Friendly Control System:

Features a PLC integrated system with separate control for each

machine.

Equipped with a touch screen panel for easy operation, monitoring,

and emergency stopping.

Quality Materials:

All parts that come into contact with plastic and water are made of

high-quality 304 stainless steel to prevent secondary contamination

of flakes.

Effective Impurity Removal:

Ensures an ideal impurity removal effect for clean recycled PET

flakes.

Company Introduction

Chengdu PuRui Polymer Engineering Co. Ltd is one of the leading

manufacturers of plastic recycling machines, extruder, plastic

granulator and related auxiliary equipment in China.

Our plastic pelletizing system's unique advantages are screw

design, high output, good degassing and good filter effect.

Our plastic washing line such as crusher with bearable resistance

and sharp cutter, washing units, separating or sorting machine,

drying system, and packaging system are of sound quality.

|