| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | VFD Frequency Inverter |

|---|---|

| Brand Name: | COENG |

| Model Number: | HV500 |

| Certification: | EC |

| Place of Origin: | China |

| MOQ: | 1 |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 20000sets/year |

| Delivery Time: | 10-30working days |

| Packaging Details: | Carton, plywood case |

| Protection Grade: | IP20 |

| Cooling Way: | Forced Air Cooling |

| Efficiency: | 5.5kW~22kW: ≥93%; Above 30kW: ≥95% |

| Input Voltage: | 200V (-15%) ~240V (+10%) 3Phase , 380V (-15%) ~480V (+10%) 3Phase, 500V (-15%) ~690V (+10%) 3Phase |

| Input Frequency: | 50Hz/60Hz±5% |

| Output Voltage: | 0V~Input voltage |

| Output Frequency: | 0Hz~500Hz |

| Company Info. |

| SHENZHEN COENG TECH CO., LTD. |

| Verified Supplier |

| View Contact Details |

| Product List |

PERFORMANCE CHARACTERISTICS

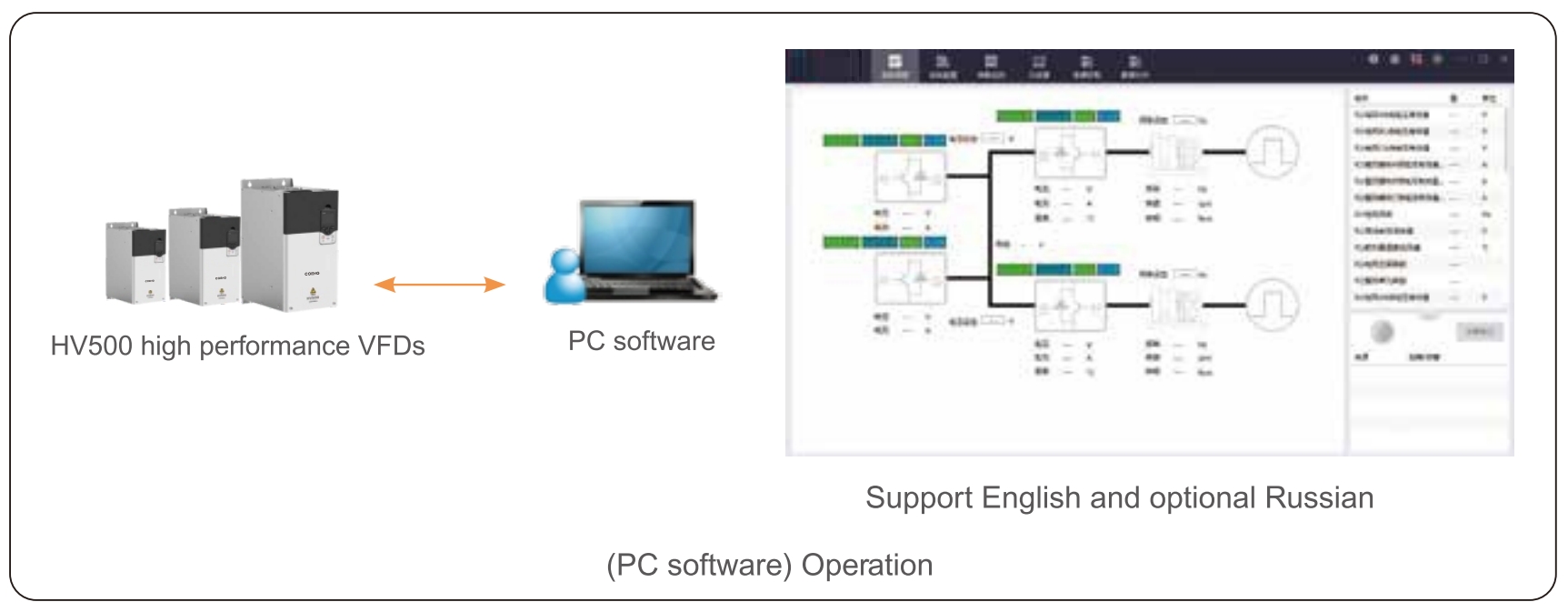

Back-end quick debugging software

Powerful and easy to use, with functions such as parameter setting, real-time oscilloscope, fault recording, event recording, etc.

Excellent performance

Suspending at zero speed;

Torque response 1-3ms;

Extremely low dynamic speed drop and dynamic speed drop equivalent;

Excellent robustness;

Accurate off-line/online motor model identification.

Various needs satisfied

Standard LCD panel to improve user experience;

Master-slave control function;

Expandable communication card, encoding disk card, voltage

detection card.

Ease of use

External 24V DC input power supported;

A Built-in brake unit is possible to save installation control;

Book style design to support seamless side-by-side installation.

Universality

Several international standard certifications passed, conforming to

RoHS directives;

V/F, OLVC and CLVC control supported;

Several communication protocols supported;

Asynchronous and permanent magnet synchronous motors supported.

Durability

Mechanical vibration level 3M3;

Independent air duct design;

Conformal coating automatic spraying;

Built-in dynamic junction temperature model to facilitate product

safety application.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Here is an introduction to the functions of variable frequency drives (VFDs):

Speed Control

Torque Control

Energy Savings

Soft Start

Operational Flexibility

Improved Process Control

Reduced Wear and Tear

Remote Monitoring and Control

Protection Features

Harmonic Mitigation

Variable frequency drives play a crucial role in modern industrial applications, providing efficient control of motor operations while promoting energy savings and equipment longevity. Their versatility makes them essential for various sectors, including manufacturing, HVAC, and renewable energy systems.

|