| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Heat Exchanger Baffle |

|---|---|

| Brand Name: | YUHONG |

| Model Number: | ASTM182 |

| Certification: | ABS, GL, DNV, NK, PED, AD2000, GOST9941-81, CCS, ISO 9001-2015 |

| Place of Origin: | China |

| MOQ: | 500KGS |

| Price: | NEGOTIABLE |

| Payment Terms: | L/C, T/T |

| Supply Ability: | According To Client's Request |

| Delivery Time: | 10-90 Days |

| Packaging Details: | Ply-wooden Case /Iron Case/ Bundle with plastic Cap |

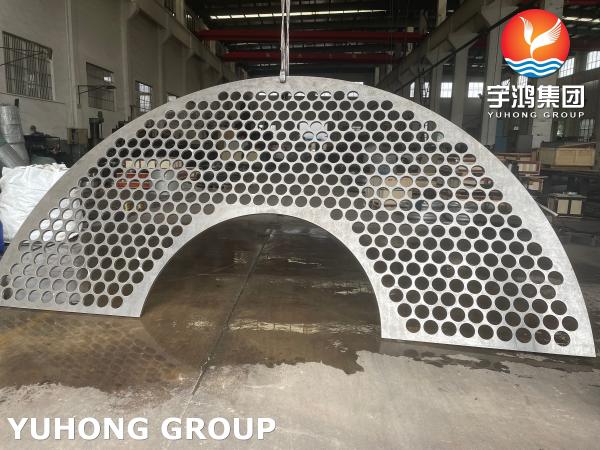

| Support Plate: | ASTM A182 |

| Size: | Various sizes available |

| Thickness: | customizable |

| Heat Exchanger Type: | Shell and Tube |

| Application: | Industrial |

| Dimension: | ASTM, ANSI, API, JIS, ASME, and DIN etc. |

| Company Info. |

| Yuhong Group Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

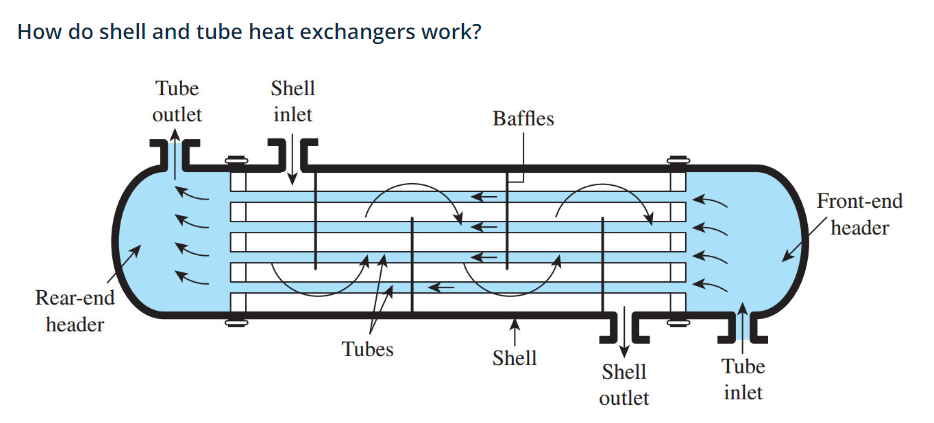

The main functions include:

1. Improve heat transfer efficiency: By changing the flow direction

and speed of the fluid, the baffle can help increase the contact

between the fluid and the tube wall, thereby improving the heat

transfer efficiency.

2. Prevent fluid short circuit: Ensure that the fluid flows along

the designed path to avoid flowing directly from the inlet to the

outlet without sufficient heat exchange.

3. Support structure: In some designs, the baffle also plays a role

in supporting the heat exchange tube, especially when there is no

other support structure inside the heat exchanger.

The design of the baffle needs to be determined according to the specific working conditions, such as the properties of the fluid (such as viscosity, corrosiveness), the required heat transfer efficiency, the allowable pressure loss and other factors. Proper design and installation of baffles are essential to ensure the performance of the heat exchanger.

1. Chemical Processing Industry

2. Food and Beverage Industry

3. Power Generation

4. Petrochemical Industry

5. Biotechnology Industry

6. Aerospace Industry

7. Automotive Industry

8. Medical Industry

|