| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Ceramic Filling Pump |

|---|---|

| Brand Name: | XQ |

| Model Number: | XQX3 system |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1 SET |

| Price: | USD 500-2000 Per Set |

| Payment Terms: | T/T |

| Supply Ability: | 100 Sets per month |

| Delivery Time: | 10 days |

| Packaging Details: | Wooden Packing |

| Machine for: | MEDICAL and liquid filling |

| Filling range: | 1-50ml and can be customizing |

| Material contact: | Stainless steel 316L and High purity zirconia |

| machine for: | Filling machine system upgrading |

| Volume adjust: | by touch screen and servo motor |

| Company Info. |

| Foshan Xiong Qi Intelligent Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

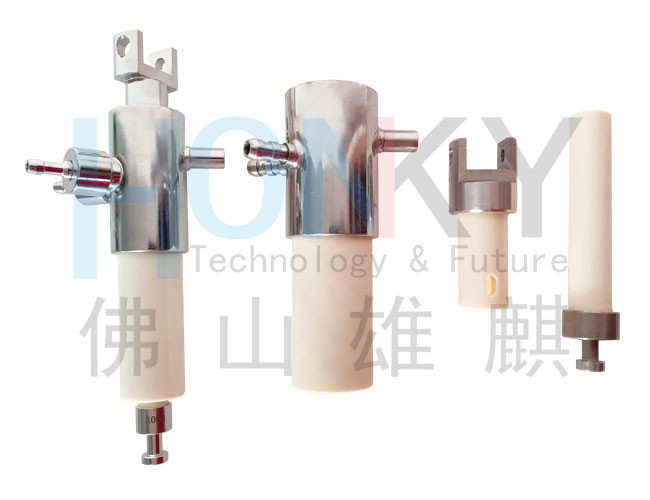

Servo Control S Series Ceramic Piston Filling Pump With High Precsion Filling System For The Pharma Liquid Filling And Dispensing

Features of Servo Control S Series Ceramic Piston Filling Pump

The XQS system series stands as a pioneering high-precision filling machine, seamlessly integrated with the state-of-the-art ceramic metering pump of the XQS series. This sophisticated model features an intuitive design, allowing for effortless adjustment of the filling volume solely through its user-friendly screen interface, thereby eliminating the necessity for manual control or intervention. This innovative feature ensures unparalleled accuracy and consistency throughout the filling process.

Due to its remarkable precision and versatility, the XQS system series is widely employed across diverse industries. In the cosmetics sector, it guarantees the precise dispensing of lotions, creams, and other beauty products. In the pharmaceutical industry, it aids in the accurate filling of medications and health supplements. Furthermore, it plays a vital role in the medical field, particularly in the preparation of sterile solutions and injectables. Its application also spans other industries that demand meticulous filling operations.

As businesses continuously strive for improvement and technological advancements, the XQS system series emerges as the optimal filling system for upgrading existing machines. It not only boosts operational efficiency but also guarantees product quality and consistency, making it an invaluable asset for companies aiming to maintain a competitive edge in their respective markets.

Application of Servo Control S Series Ceramic Piston Filling Pump

--Using a high-performance motor to realize extremely fast and

automatic adjustment of the filling volume, which is accurate and

stable.

--The operation of the pump will not produce trace impurities to

pollute the liquid and can be quickly disassembled and assembled.

Industry application:

--It can be used for matching and modification of the filling part

of the packaging machine. Suitable for filling electrolyte,

medicine, biochemical reagent, chemical liquid, etc.

Parameter of Servo Control S Series Ceramic Piston Filling Pump

| Model | SS-10-12 | Others |

| Pump Material | According to the XQS's parameter | |

| Out-frame | SS 304 | |

| Pump head | 12 sets | Customized |

| Power supply | AC 220V 50/60hz | |

| Pump size | 1130*310*480mm | Customized |

| Pump weight | 130Kg | Customized |

| Power | 2000W | Customized |

| Configuration | Customized | Customized |

Product display of Servo Control S Series Ceramic Piston Filling Pump

Advantages of using the ceramic:

1. Low Friction, Increased Packing Life

2. Extreme Wear Resistance

3. Increased Corrosion Resistance

4. Improved Anti-Galling Surface

Q & A

Q: Do you offer OEM services, I am a distributor from overseas?

A: Yes, we can offer both OEM Services and technical support.

Welcome to start your OEM business.

Q: How about the after-sales service?

A: The machine is a 1-year warranty. And we offer lifetime

after-sale service and technical support.

Q: What are your Installation Services?

A: Installation Services are available with all new machine

purchases. We will provide the user manual and videos to support

installing, debugging, operation of the machine, which will

indicate to you how to use this machine well.

Q: What info will be needed to confirm machine models?

A: 1.The material status.

2. Filling range.

3. Manufacturing speed.

4. Requirements for the production process.

|