| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | NiCr Alloy |

|---|---|

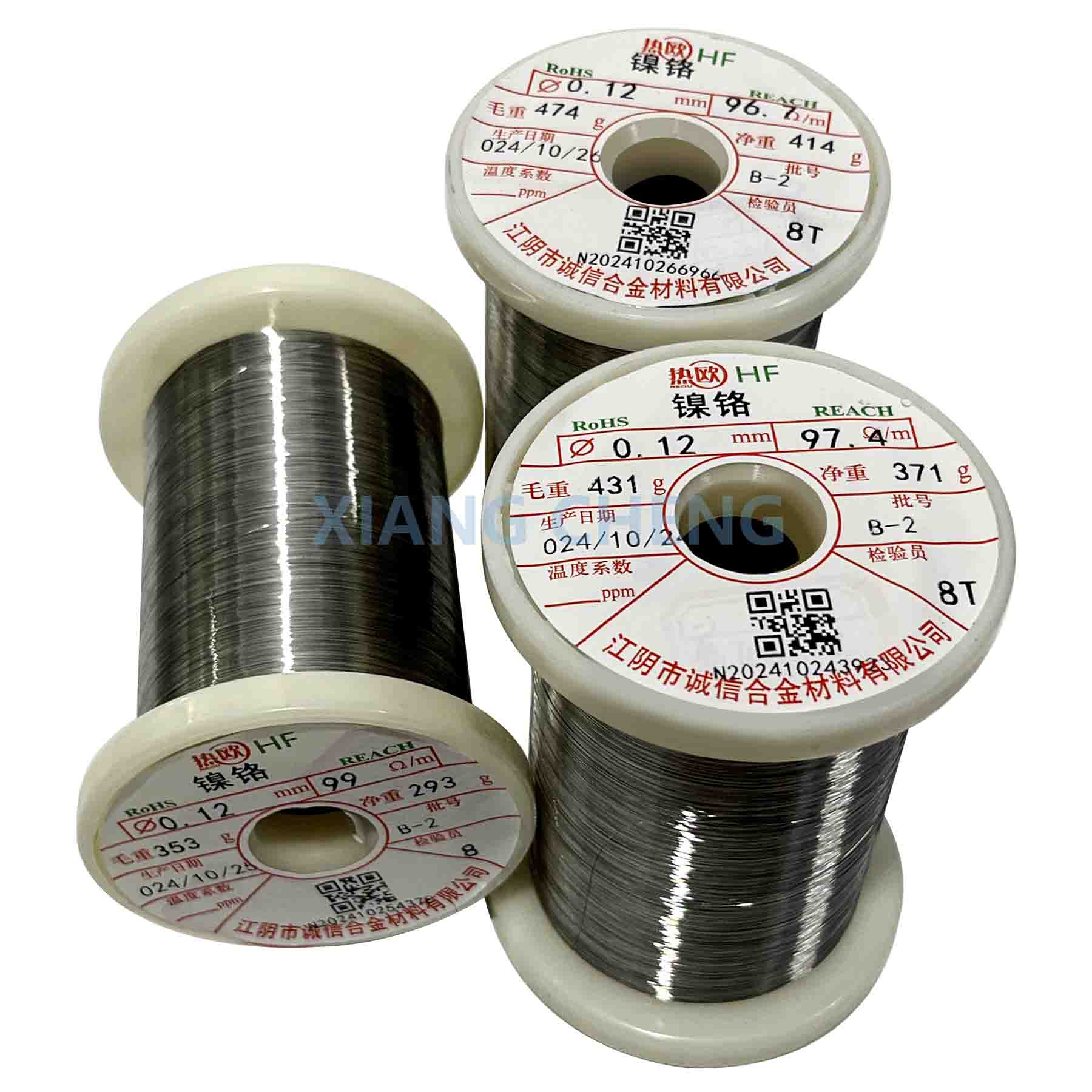

| Brand Name: | Senphus |

| Model Number: | Cr15Ni60/60Ni16Cr/NiCr6015 |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 5kg |

| Payment Terms: | T/T, D/P |

| Supply Ability: | 30 Tons per day |

| Delivery Time: | 3 days |

| Packaging Details: | Packed with waterproof paper or weave bag, into pallets or wooden case. Special packaging requirements can also be accommodated. |

| Place of Orig: | China |

| Type: | Ni-Cr-Fe alloys |

| Application: | Heating element and resistor |

| Color: | Shiny silver or dark gray |

| Density: | 8.20 |

| Resistivity at 20 ℃: | 1.12±0.05 |

| Melting point(℃): | 1390 |

| Thermal conductivity: | 45.2(KJ/mh ℃) |

| Elongation at rupture(% ): | >20 |

| Company Info. |

| Jiangyin Chengxin Alloy Material Co., Ltd , |

| Verified Supplier |

| View Contact Details |

| Product List |

Cr15Ni60/60Ni16Cr/NiCr6015 NiCr Alloys Essential Materials for Metallurgical Industries

| GB | JIS | ASTM | DIN EN/DIN | GOST |

| Cr15Ni60 |

NCHW-2 NCHR-2 | 60Ni16Cr | NiCr6015 | Х15Н60-Н |

Main characteristics of Ni-Cr and Ni-Cr-Fe electric heating alloys

Type

| Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni80 | Cr20Ni30 | Cr25Ni20 | |

| Main Chemical composition | Ni | Rest | 55.0-61.0 | 34.0-37.0 | Rest | 30.0-34.0 | 19.0-22.0 |

| Cr | 28.0-31.0 | 15.0-18.0 | 18.0-21.0 | 20.0-23.0 | 18.0-21.0 | 24.0-26.0 | |

| Fe | ≤ 1.0 | Rest | Rest | ≤ 1.0 | Rest | Rest | |

| Max. continuous service temp. of element (℃) | 1250 | 1150 | 1100 | 1200 | 1100 | 1050 | |

| Resistivity at 20 ℃(μΩm) | 1.18±0.05 | 1.12±0.05 | 1.04±0.05 | 1.09±0.05 | 1.06±0.05 | 0.95±0.05 | |

| Density(g/cm3) | 8.10 | 8.20 | 7.90 | 8.40 | 7.90 | 7.15 | |

| Thermal condyctivity (KJ/m·h·℃) | 45.2 | 45.2 | 43.8 | 60.3 | 43.8 | 43.8 | |

| Coefficient of lines expansion (α×10-6/℃) | 17.0 | 17.0 | 19.0 | 18.0 | 19.0 | 19.0 | |

| Melting point (approx.)(℃) | 1380 | 1390 | 1390 | 1400 | 1390 | 1400 | |

| Elonation at rupture(%) | >20 | >20 | >20 | >20 | >20 | >20 | |

| Micrographic structure | Austenite | Austenite | Austenite | Austenite | Austenite | Austenite | |

| Magnetic properties | Non-magnetic | Low-magnetic | Low-magnetic | Non-magnetic | Low-magnetic | Non-magnetic | |

| Note:The various grades of electric resistance alloy material are blended with the amountof rare earth, titanium and other trace elements, to improve the processing performance andextend the period of the uselife. | |||||||

| Chemical Composition Wt.% Cr15Ni60 | % | Ni | Fe | C | Si | Mn | P | S | Cr | Al |

| Min | 55 | 0.75 | 15 | |||||||

| Max | 61 | Rest | 0.08 | 1.6 | 0.6 | 0.02 | 0.015 | 18 | 0.5 |

| Mechanical properties | Condition | Tensile Strength (UTS)(Rm) | Elongation(A5) | |||

| D>3, T>0.2 | ≥600 MPa | ≥25% | ||||

| 0.1<D<0.3, T>0.2 | ≥600 MPa | ≥20% | ||||

Some key features of Cr15Ni60 include:

High Electrical Resistivity: Cr15Ni60 has a high electrical resistivity, which is crucial for applications requiring precise control of electrical resistance, such as in heating elements and precision resistors.

Corrosion Resistance: This alloy is highly resistant to corrosion, particularly in oxidizing environments. It performs well in conditions involving nitrogen, ammonia, and sulfur-containing atmospheres, making it ideal for chemical processing and other corrosive environments.

High-Temperature Strength: Cr15Ni60 maintains its strength and resistivity at elevated temperatures, with a maximum working temperature of around 1150°C. This makes it suitable for use in high-temperature industrial processes and furnace components.

Thermal Stability: The alloy exhibits good thermal stability, which is essential for applications where consistent performance over a wide temperature range is required.

Low Coefficient of Thermal Expansion: With a low coefficient of thermal expansion, Cr15Ni60 experiences minimal dimensional changes with temperature fluctuations, which is beneficial for maintaining precision in high-temperature applications.

Mechanical Properties: The alloy has good mechanical properties, including tensile strength and elongation, which contribute to its durability and reliability in various applications.

Weldability: Cr15Ni60 is relatively easy to weld, which is an advantage in applications where components need to be joined without compromising the material's integrity.

Formability: The alloy is formable, allowing it to be shaped into various configurations, which is beneficial for manufacturing complex components.

Applications:

Heating Elements: Cr15Ni60 is used as heating elements in periodic heat treatment furnaces operating below 900°C

Electrical Resistance Applications: It is utilized in high-grade electric heat pipes and domestic electric heaters as the heating wire

Resistor Bands: Cr15Ni60 is employed in high-quality resistance boxes for resistor bands

Industrial Furnaces: The alloy is extensively used in industrial furnaces as electric heating elements due to its excellent oxidation resistance and high-temperature strength

Heat Treatment Equipment: Cr15Ni60 is used in the manufacturing of high-temperature furnace linings and thermocouple protection tubes in heat treatment equipment, ensuring precision and consistency in the heat treatment process

Aerospace Industry: In the aerospace field, Cr15Ni60 is used for high-temperature components such as gas turbines and jet engines, providing reliable protection due to its high-temperature oxidation resistance and mechanical strength

Resistors: The alloy is also used in the manufacture of various types of resistors, especially in applications requiring high stability and long life, such as precision instruments and electrical equipment

Technical data of wires

| Dia. (mm) | Cross-sectional area (mm²) | Weight/Meter (g/m) | Resistance/Meter at 20 ℃ (Ω/m) | Dia. (mm) | Cross-sectional area (mm²) | Weight/Meter (g/m) | Resistance/Meter at 20 ℃ (Ω/m) |

| 0.018 | 0.000255 | 0.002117 | 3410-4610 | 0.25 | 0.04909 | 0.4074 | 20.88-23.54 |

| 0.020 | 0.000314 | 0.002606 | 2940-3740 | 0.28 | 0.06158 | 0.5111 | 16.64-18.76 |

| 0.022 | 0.000380 | 0.003154 | 2440-3100 | 0.30 | 0.07069 | 0.5867 | 14.49-16.35 |

| 0.025 | 0.000491 | 0.004075 | 1880-2400 | 0.32 | 0.07548 | 0.6265 | 12.74-14.36 |

| 0.028 | 0.000616 | 0.005113 | 1530-1870 | 0.33 | 0.08553 | 0.7099 | 12.20-13.40 |

| 0.030 | 0.000707 | 0.005868 | 1338-1696 | 0.38 | 0.1134 | 0.9412 | 9.13-10.09 |

| 0.032 | 0.000804 | 0.006673 | 1180-1440 | 0.40 | 0.1257 | 1.0433 | 8.24-9.108 |

| 0.035 | 0.000962 | 0.007985 | 981-1200 | 0.41 | 0.132 | 1.0956 | 7.68-8.89 |

| 0.040 | 0.001257 | 0.01043 | 780.7-954.1 | 0.45 | 0.159 | 1.3197 | 6.51-7.196 |

| 0.045 | 0.00159 | 0.0132 | 594-726 | 0.50 | 0.1963 | 1.6293 | 5.273-5.829 |

| 0.050 | 0.001963 | 0.01629 | 499.6-610.6 | 0.55 | 0.2376 | 1.9721 | 4.518-4.994 |

| 0.055 | 0.00238 | 0.01975 | 407-477 | 0.60 | 0.2827 | 2.3464 | 3.797-4.197 |

| 0.063 | 0.00312 | 0.02590 | 321.41-377.31 | 0.65 | 0.3318 | 2.7539 | 3.235-3.575 |

| 0.070 | 0.00385 | 0.03196 | 260.5-305.9 | 0.70 | 0.3848 | 3.1938 | 2.789-3.083 |

| 0.080 | 0.005027 | 0.04172 | 199.5-234.1 | 0.75 | 0.4418 | 3.6669 | 2.43-2.686 |

| 0.090 | 0.006362 | 0.0528 | 157.6-185.0 | 0.80 | 0.5027 | 4.1724 | 2.136-2.36 |

| 0.100 | 0.007854 | 0.0652 | 127.7-149.9 | 0.85 | 0.5674 | 4.7094 | 1.891-2.091 |

| 0.110 | 0.009852 | 0.08177 | 105.5-123.9 | 0.90 | 0.6362 | 5.2805 | 1.687-1.865 |

| 0.120 | 0.01227 | 0.1018 | 88.67-104.1 | 0.95 | 0.7088 | 5.883 | 1.46-1.62 |

| 0.140 | 0.01539 | 0.1277 | 65.85-75.77 | 1.00 | 0.7854 | 6.5188 | 1.367-1.511 |

| 0.150 | 0.01767 | 0.1467 | 56.75-66.63 | 1.10 | 0.9503 | 7.8875 | 1.13-1.26 |

| 0.160 | 0.02011 | 0.01669 | 50.42-58.00 | 1.12 | 0.9852 | 8.1772 | 1.05-1.17 |

| 0.170 | 0.022700 | 0.1884 | 44.18-51.86 | 1.18 | 1.0936 | 9.0769 | 0.95-1.05 |

| 0.180 | 0.02545 | 0.2112 | 40.26-45.40 | 1.20 | 1.313 | 10.8979 | 0.79-0.87 |

| 0.190 | 0.02835 | 0.2353 | 35.37-41.53 | 1.30 | 1.327 | 11.0141 | 0.78-0.86 |

| 0.200 | 0.03142 | 0.2608 | 32.62-36.78 | 1.40 | 1.539 | 12.7737 | 0.70-0.77 |

| 0.212 | 0.035300 | 0.2930 | 28.41-33.35 | 1.50 | 1.767 | 14.6661 | 0.60-0.67 |

| 0.220 | 0.03801 | 0.3155 | 26.65-30.39 | 1.60 | 2.011 | 16.8924 | 0.52-0.58 |

The tolerance or wires diameter

| Wires | Dia.(mm) | Tolerance |

| 0.018-0.025 | ±0.001 | |

| 0.028-0.035 | ±0.0015 | |

| 0.040-0.055 | ±0.002 | |

| 0.070 | ±0.0025 | |

| 0.08-0.10 | ±0.003 | |

| 0.11-0.14 | ±0.004 | |

| 0.16-0.20 | ±0.005 | |

| 0.22-0.25 | ±0.006 | |

| 0.28-0.30 | ±0.007 | |

| 0.32-0.40 | ±0.01 | |

| 0.41-0.50 | ±0.015 | |

| 0.55-0.80 | +0.02/-0.03 | |

| 0.85-1.00 | +0.02/-0.03 | |

| 1.10-1.50 | ±0.03 | |

| Note:special specification can be produced as per client's request. | ||

Technical data of ribbon

| Thickness × Width(mm) | Resistance/meter(20 ℃) (Ω/m) | Surface area/ohm (20℃) (cm2/Ω) | Weight/meter (g/m) | Surface area/meter (cm2/m) |

| 0.09x2.5 | 5.27 | 9.84 | 1.72 | 51.8 |

| 0.08x0.2 | 74 | 0.0756 | 0.122 | 5.6 |

| 0.08x0.3 | 49.4 | 0.154 | 0.183 | 7.6 |

| 0.08x0.4 | 37 | 0.259 | 0.244 | 9.6 |

| 0.08x0.5 | 29.6 | 0.392 | 0.305 | 11.6 |

| 0.08x0.6 | 24.7 | 0.551 | 0.367 | 13.6 |

| 0.08x0.7 | 21.2 | 0.737 | 0.428 | 15.6 |

| 0.08x0.8 | 18.5 | 0.951 | 0.489 | 17.6 |

| 0.08x0.9 | 16.5 | 1.19 | 0.55 | 19.6 |

| 0.08x1.0 | 14.8 | 1.46 | 0.611 | 21.6 |

| 0.08x1.2 | 12.3 | 2.07 | 0.733 | 25.6 |

| 0.08x1.5 | 9.87 | 3.2 | 0.916 | 31.6 |

| 0.08x1.8 | 8.23 | 4.57 | 1.1 | 37.6 |

| 0.08x2.0 | 7.4 | 5.62 | 1.22 | 41.6 |

| 0.07x0.2 | 84.6 | 0.0638 | 0.107 | 5.4 |

| 0.07x0.3 | 56.4 | 0.131 | 0.16 | 7.4 |

| 0.07x0.4 | 42.3 | 0.222 | 0.214 | 9.4 |

| 0.07x0.5 | 33.9 | 0.337 | 0.267 | 11.4 |

| 0.07x0.6 | 28.2 | 0.475 | 0.321 | 13.4 |

| 0.07x0.7 | 24.2 | 0.637 | 0.374 | 15.4 |

| 0.07x0.8 | 21.2 | 0.822 | 0.428 | 17.4 |

| 0.07x0.9 | 18.8 | 1.03 | 0.481 | 19.4 |

| 0.07x1.0 | 16.9 | 1.26 | 0.535 | 21.4 |

| 0.07x1.2 | 14.1 | 1.8 | 0.641 | 25.4 |

| 0.07x1.5 | 11.3 | 2.78 | 0.802 | 31.4 |

| 0.06x0.2 | 98.7 | 0.0527 | 0.0916 | 5.2 |

| 0.06x0.3 | 65.8 | 0.109 | 0.137 | 7.2 |

| 0.06x0.4 | 49.4 | 0.186 | 0.183 | 9.2 |

| 0.06x0.5 | 39.5 | 0.284 | 0.229 | 11.2 |

| 0.06x0.6 | 32.9 | 0.401 | 0.275 | 13.2 |

| 0.06x0.7 | 28.2 | 0.539 | 0.321 | 15.2 |

| 0.06x0.8 | 24.7 | 0.697 | 0.367 | 17.5 |

| 0.06x0.9 | 21.9 | 0.875 | 0.412 | 19.2 |

| 0.06x1.0 | 19.7 | 1.07 | 0.458 | 21.2 |

| 0.06x1.2 | 16.5 | 1.53 | 0.55 | 25.2 |

| 0.05x0.2 | 118 | 0.0422 | 0.0764 | 5.00 |

| 0.05x0.3 | 79 | 0.0886 | 0.115 | 7.00 |

| 0.05x0.4 | 59.2 | 0.152 | 0.153 | 9.00 |

| 0.05x0.5 | 47.4 | 0.232 | 0.191 | 11.00 |

| 0.05x0.6 | 39.5 | 0.329 | 0.229 | 13.00 |

| 0.05x0.7 | 33.9 | 0.443 | 0.267 | 15.0 |

| 0.05x0.8 | 29.6 | 0.574 | 0.305 | 17.0 |

| 0.05x0.9 | 16.3 | 0.722 | 0.344 | 19.0 |

| 0.05x1.0 | 23.7 | 0.886 | 0.382 | 21.0 |

| Ribbon is rolled by the wire, the actual cross-sectional area of the ribbon is smaller 8% than calculated by the rectangular. | ||||

|