| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Metal Nut |

|---|---|

| Brand Name: | JIA SHAN |

| Model Number: | DIN, ASEM, ISO |

| Certification: | ISO |

| Place of Origin: | China |

| MOQ: | 100 |

| Price: | USD0.2/pcs-USD1/pcs |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | Batch order abailable |

| Delivery Time: | 1-5 weekds |

| Usage: | Fastening |

| Style: | Wire Thread Insert |

| Size: | Various sizes available |

| Head Style: | Wire Thread Insert |

| Strength: | High |

| Finish: | Plain |

| Manufacturer: | JIA SHAN Hardward Company |

| Length: | As customisation |

| Package: | Small Packing+Carton Packing+Pallet |

| Standard: | DIN |

| Package Quantity: | 100 pieces |

| Shape: | Wire Thread Insert |

| Measurement System: | INCH, Metric |

| Port: | Shenzhen |

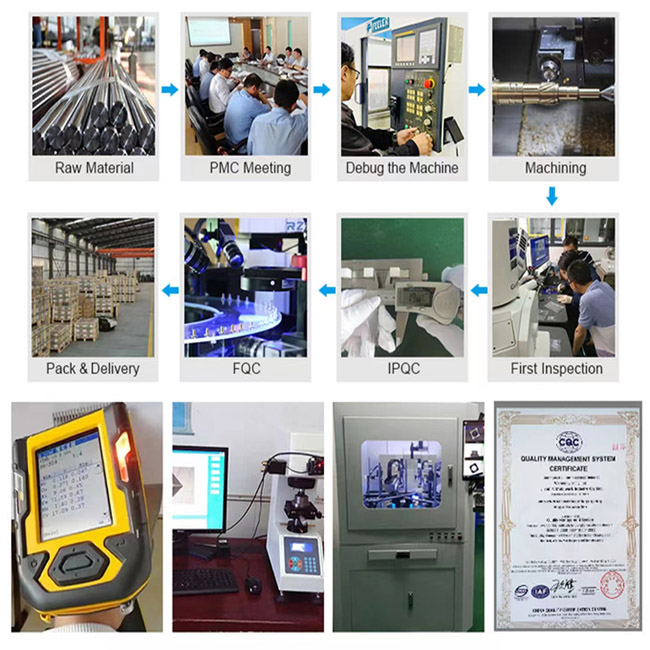

| Quality: | Inspection before shipment |

| Color: | As customisation |

| Material: | stainless steel |

| Company Info. |

| Hunan Jia Shan Hardware Tech Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

M8 M10 Stainless steel wire thread insert SS304 SS316 A2 A4-80 for

Automotive Mechanical

Product Description:

Applications:

• Aerospace: Used extensively in the repair and assembly of aircraft and spacecraft components, where high precision and strength are required.

Stainless Steel Applications in Modern Industries

Stainless steel is an alloy of iron with a minimum of 10.5% chromium content, offering superior corrosion resistance, strength, and durability. Due to these properties, stainless steel has a wide range of applications in various industries. Below are some key uses:

1. Construction and Architecture

Stainless steel is commonly used in the construction industry for structural components, exterior facades, and decorative elements. Its resistance to rust and staining makes it ideal for buildings exposed to harsh weather conditions. For example, stainless steel is often used in the frames of windows, handrails, roofing, and cladding of tall buildings, such as skyscrapers. Landmarks like the Eiffel Tower and St. Paul’s Cathedral incorporate stainless steel for both structural integrity and aesthetic appeal.

Moreover, stainless steel is also used in public infrastructure, such as bridges and tunnels, especially in coastal regions or places with high humidity, where the material’s resistance to corrosion helps increase the longevity of the structures.

2. Food and Beverage Processing

In the food industry, stainless steel is a preferred material due to its non-reactivity and hygienic qualities. It is widely used in food processing equipment, storage tanks, pipes, and kitchen appliances. Stainless steel’s smooth surface prevents the accumulation of bacteria and is easy to clean, making it suitable for high-sterility environments like food production and commercial kitchens. Stainless steel is also used in brewing equipment, dairy machinery, and meat processing facilities.

3. Medical Devices and Healthcare Equipment

Stainless steel’s corrosion resistance and biocompatibility make it an essential material in the healthcare sector. It is used in surgical instruments, dental implants, medical devices, and hospital furniture. Stainless steel’s ability to withstand sterilization processes and its strength ensure that it can endure the rigorous demands of medical environments, ensuring both safety and reliability. Surgical tools such as scalpels, forceps, and needles are commonly made from stainless steel.

4. Automotive and Aerospace

In the automotive industry, stainless steel is used for exhaust systems, trim, and structural components. Its high resistance to high temperatures and corrosion makes it an excellent choice for parts exposed to exhaust gases and extreme conditions. Stainless steel’s strength and lightweight properties also make it valuable in aerospace applications, particularly in engine components, structural parts, and fuel tanks. Aircraft manufacturers choose stainless steel for its ability to handle the stresses of flight and for its resistance to the harsh conditions found at high altitudes.

Steel types:

| No. | C% | Cr% | Ni % | Mo % |

| 304 | 0.07 | 17.5-19.5 | 8.0-10.5 | / |

| 316 | 0.08 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 |

| 301 | 0.15 | 16.0-18.1 | 6-8 | / |

| 310 | 0.08 | 24-26 | 19-22 | / |

| 304L | 0.03 | 18-20 | 8-12 | / |

| 316L | 0.03 | 16-18 | 10-14 | 2-3 |

| 321 | 0.08 | 17-19 | 9-12 | / |

201, 304, 316 are austenitic stainless steel, according to the

performance of the non-magnetic, some of the performance of the

weak magnetic because of the smelting of the composition of the

segregation or improper heat treatment leads to the austenite in a

small amount of martensite or ferrite. Austenitic stainless steel

corrosion resistance comes from the formation of chromium oxide

protective layer on the metal surface. When the material

temperature is heated to 450 degrees -900 degrees, the structure

changes, will form chromium carbide along the edge of the crystal

and can not form a protective layer of chromium oxide, thus

reducing the corrosion resistance, this is also known as

‘intergranular corrosion’. As a result, there are 304L and 316L,

the two due to the low carbon content also reduces the

intergranular corrosion. In particular, the higher susceptibility

to intergranular corrosion does not mean that non-low carbon

content is more susceptible to corrosion, in a highly chlorinated

environment, this susceptibility is also higher.

304 stainless steel

304 is a general-purpose stainless steel that is widely used to

make equipment and machine parts that require good all-round

performance (corrosion resistance and formability). In order to

maintain the corrosion resistance inherent in stainless steel, the

steel must contain more than 18% chromium, more than 8% nickel content. 304 stainless steel is a grade of

stainless steel produced according to the American ASTM standard.

About Us

Package

|