YRT Rotary Table Bearings

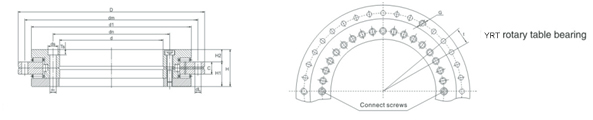

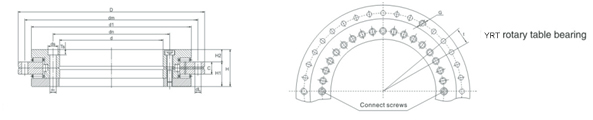

| YRT basic rotary table bearings are designed with a radial full roller, two groups of axial needle roller, cage assembly, an out ring, an L-section inner ring, and the second ring. The out ring and inner ring are equipped with fixing holes, allowing the bolt to secure the bearings directly. The YRT rotary table bearing structure is capable of bearing double-direction axial load, radial load, and tilting moment. This series bearing has a preload applied prior to leaving the factory, eliminating the need for clearance adjustments during installation. This series bearing is particularly well-suited for applications requiring high precision, high stiffness, low speed, and a short rotate period, such as rotary tables, index heads, and revolving milling heads.

This bearing offers axial and radial running precision to suit your specific requirements. |

Features

1. High precision: P4 precision, P2 precision

2. High rigidity: This series bearing have preload

3. High load:This series bearing can bear double-direction axial load, radial load and tilting moment

4. High speed: YRTS series bearing can be applied to the situation of high rotating speed

Specifications

| Model | Dimension |

| d | D | H | H1 | H2 | C | d1 | dn | dm |

| Unit:mm |

| YRT50 | 50 | 126 | 30 | 20 | 10 | 10 | 105 | 63 | 116 |

| YRT80 | 80 | 146 | 35 | 23.35 | 11.65 | 12 | 130 | 92 | 138 |

| YRT100 | 100 | 185 | 38 | 25 | 13 | 12 | 160 | 112 | 170 |

| YRT120 | 120 | 210 | 40 | 26 | 14 | 12 | 184 | 135 | 195 |

| YRT150 | 150 | 240 | 40 | 26 | 14 | 12 | 214 | 165 | 225 |

| YRT180 | 180 | 280 | 43 | 29 | 14 | 15 | 244 | 194 | 260 |

| YRT200 | 200 | 300 | 45 | 30 | 15 | 15 | 274 | 215 | 285 |

| YRT260 | 260 | 385 | 55 | 36.5 | 18.5 | 18 | 345 | 280 | 365 |

| YRT325 | 325 | 450 | 60 | 40 | 20 | 20 | 415 | 342 | 430 |

| YRT395 | 395 | 525 | 65 | 42.5 | 22.5 | 20 | 486 | 415 | 505 |

| YRT460 | 460 | 600 | 70 | 46 | 24 | 22 | 560 | 482 | 580 |

| YRT580 | 580 | 750 | 90 | 60 | 30 | 30 | 700 | 610 | 720 |

| YRT650 | 650 | 870 | 122 | 78 | 44 | 34 | 800 | 680 | 830 |

| YRT850 | 850 | 1095 | 124 | 80.5 | 43.5 | 37 | 1018 | 890 | 1055 |

| YRT950 | 950 | 1200 | 132 | 86 | 46 | 40 | 1130 | 990 | 1160 |

| YRT1030 | 1030 | 1300 | 145 | 92.5 | 52.5 | 40 | 1215 | 1075 | 1255 |

| YRT1200 | 1200 | 1490 | 164 | 108 | 56 | 52 | 1410 | 1240 | 1445 |

| Model | Fixing hole | Joint screw QTY | Lifting hole | Pitch1)t | Screw tightening torque | Screw tightening torque | Limiting speed5) | Bearing friction torque3) | Mass |

| Axial | Radial |

| Inner ring | Outer ring | Dynamic | Static | Dynamic | Static |

| do | ds | Ts | QTY4) | dL | QTY4) | MA2) | Ca | Coa | Cr | Cor | Grease |

| mm | mm | G | QTY | QTY*t | N m | KN | r/min | Nm | ≈Kg |

| YRT50 | 5.6 | 9 | 4.2 | 10 | 5.6 | 12 | 2 | / | / | 12*30° | 8.5 | 38 | 158 | 28.5 | 49.5 | 600 | 2.5 | 1.6 |

| YRT80 | 5.6 | 10 | 4.2 | 10 | 4.6 | 12 | 2 | / | / | 12*30° | 8.5 | 56 | 255 | 42.5 | 100 | 530 | 3 | 2.4 |

| YRT100 | 5.6 | 10 | 5.4 | 16 | 5.6 | 15 | 2 | M5 | 3 | 18*20° | 8.5 | 76.5 | 415 | 47.5 | 120 | 430 | 3 | 4.1 |

| YRT120 | 7 | 11 | 6.2 | 22 | 7 | 21 | 2 | M8 | 3 | 24*15° | 14 | 102 | 540 | 52 | 143 | 340 | 7 | 5.3 |

| YRT150 | 7 | 11 | 6.2 | 34 | 7 | 33 | 2 | M8 | 3 | 36*10° | 14 | 112 | 630 | 56 | 170 | 320 | 10 | 6.2 |

| YRT180 | 7 | 11 | 6.2 | 46 | 7 | 45 | 2 | M8 | 3 | 48*7.5° | 14 | 118 | 710 | 69.5 | 200 | 280 | 12 | 7.7 |

| YRT200 | 7 | 11 | 6.2 | 46 | 7 | 45 | 2 | M8 | 3 | 48*7.5° | 14 | 120 | 765 | 81.5 | 220 | 260 | 14 | 9.7 |

| YRT260 | 9.3 | 15 | 8.2 | 34 | 9.3 | 33 | 2 | M12 | 3 | 36*10° | 34 | 160 | 1060 | 93 | 290 | 200 | 20 | 18.3 |

| YRT325 | 9.3 | 15 | 8.2 | 34 | 9.3 | 33 | 2 | M12 | 3 | 36*10° | 34 | 275 | 1930 | 120 | 345 | 170 | 40 | 25 |

| YRT395 | 9.3 | 15 | 8.2 | 46 | 9.3 | 45 | 2 | M12 | 3 | 48*7.5° | 34 | 300 | 2280 | 186 | 655 | 140 | 55 | 33 |

| YRT460 | 10 | 15 | 8.2 | 46 | 10 | 45 | 2 | M12 | 3 | 48*7.5° | 34 | 355 | 2800 | 200 | 765 | 120 | 70 | 45 |

| YRT580 | 11.4 | 18 | 11 | 46 | 11.4 | 42 | 2 | M12 | 6 | 48*7.5° | 68 | 490 | 4250 | 228 | 965 | 80 | 140 | 89 |

| YRT650 | 14 | 20 | 13 | 45 | 14 | 42 | 2 | M12 | 6 | 48*7.5° | 116 | 1040 | 8000 | 490 | 1800 | 65 | 200 | 170 |

| YRT850 | 18.5 | 26 | 17 | 57 | 18.5 | 54 | 2 | M16 | 6 | 60*6° | 284 | 1000 | 8650 | 455 | 1730 | 50 | 300 | 253 |

| YRT950 | 18.5 | 26 | 17 | 57 | 18.5 | 54 | 2 | M17 | 6 | 60*6° | 284 | 1290 | 11400 | 530 | 2040 | 40 | 600 | 312 |

| YRT1030 | 18.5 | 26 | 17 | 66 | 18.5 | 66 | 2 | M18 | 6 | 72*5° | 284 | 1380 | 12000 | 620 | 2650 | 35 | 800 | 375 |

| YRT1200 | 18.5 | 26 | 17 | 66 | 18.5 | 66 | 2 | M19 | 6 | 72*5° | 284 | 1435 | 12850 | 745 | 2800 | 25 | 1000 | 450 |

Drwaings

Application

Suzhou Giant Precision Industry Co., Ltd.

Suzhou Giant Precision Industry Co., Ltd. is a

technical-service enterprise specializing in keeping on researching

core technologies and developing high precision transmission

products. We mainly provide strain wave reducers, RV reducers, rotary actuator, planetary reducers, electric grippers.

Currently, our products have been widely used in a variety of

industrial sectors, such as manipulator, industrial robots, CNC

machine tool, printing equipment, textile machine, packaging

machinery, non-standard automation, medical equipment, laser

cutting, welding, automobile manufacturing, satellite

communications, metal processing, pharmaceutical industry, etc.

Our mission is to adhere to our service philosophy, put customer

value in our first place, to provide high-quality products,

professional technical support and diverse services.