M2.5 M5 ASTM B7 B7M Stainless Steel Male And Female Hexagon Head

Metal Standoff single studs

Product Description:

What is a standoff? As the name suggests, tstandoff is one end for

the internal thread and the other end for the external thread of a

kind of screws, broadly speaking, standoff also include both ends

are internal thread screws. Its appearance is hexagonal, play a

role in fastening and isolation, because it is generally used

hexagonal copper rod as raw material production and become, so

tstandoff is also known as copper column, hexagonal copper column,

copper isolation column or copper spacer column.

The use of standoff. Intercalated screws are mainly used in the

computer, circuit board and other industries, when one end is

screwed into the locked object, the hexagonal post is exposed to

the outside, which can fix or isolate other objects.

The main specifications of standoff are M3, M4, M5, M6, M8, M10,

etc., and their hexagonal posts were 5, 6, 8, 10, 12, 15mm, etc.,

which should be in the most or the M3 series. Material in addition

to copper an

Hexagonal studs are also known as yin and yang studs, it is one end

of the internal thread and one end of the external thread, but are

hexagonal, can play a role in fastening and isolation.

Mostly used in computers, circuit boards and other industries, when

used, when one end is screwed into the workpiece being fastened,

the hexagonal column is exposed on the surface, can be fixed or

isolated from other workpieces. Such as in the computer mainframe,

the external thread can be connected to the motherboard inside the

mainframe, the internal thread can be isolated from the motherboard

and sheet metal shell.

Applications:

Stainless Steel:

1, the basic knowledge of stainless steel

Stainless steel is an alloy material with corrosion resistance, and

its main components are an alloy of elements such as iron, chromium

and nickel. These elements can effectively resist oxidation and

corrosion, so that stainless steel has a high degree of durability

and aesthetics.

2, stainless steel maintenance methods

Cleaning

Keeping stainless steel products clean is an important part of

their maintenance. You can use mild detergents and soft cloth for

cleaning, avoid the use of detergents containing acidic and

alkaline components, so as not to damage the surface of stainless

steel. When removing dirt, you should try to avoid using irritating

cleaning tools to avoid scratching the stainless steel surface.

After cleaning, rinse with water and dry with a clean soft cloth.

3, the use of stain remover

For some stubborn dirt, you can use special stainless steel stain

remover for cleaning. But before using it, you should carefully

read and follow the instructions in the product manual. In

addition, stainless steel products on the dirt can be cleaned with

alcohol or vinegar, these common cleaners on stainless steel has a

certain decontamination effect.

Steel types:

| No. | C% | Cr% | Ni % | Mo % |

| 304 | 0.07 | 17.5-19.5 | 8.0-10.5 | / |

| 316 | 0.08 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 |

| 301 | 0.15 | 16.0-18.1 | 6-8 | / |

| 310 | 0.08 | 24-26 | 19-22 | / |

| 304L | 0.03 | 18-20 | 8-12 | / |

| 316L | 0.03 | 16-18 | 10-14 | 2-3 |

| 321 | 0.08 | 17-19 | 9-12 | / |

Stainless steel is renowned for its excellent resistance to

corrosion. This is primarily due to the presence of chromium in its

composition, which forms a thin, self-healing oxide layer on the

surface. This layer protects the steel from rust and other forms of

corrosion. This property makes stainless steel ideal for use in

harsh environments, such as marine applications, chemical

processing, and food processing industries, where exposure to

moisture, salt, or chemicals is common.

Stainless steel is incredibly strong and durable. It can withstand

significant mechanical stress and maintain its structural integrity

over long periods. Its high tensile strength and yield strength

make it suitable for applications that require robust materials. It

is commonly used in construction (e.g., structural beams,

reinforcement bars), automotive manufacturing (e.g., exhaust

systems, chassis components), and industrial machinery (e.g.,

gears, shafts).

Stainless steel has a sleek, shiny appearance that is both visually

appealing and easy to maintain. It can be polished to a mirror

finish or textured to achieve different looks. It is widely used in

consumer products (e.g., kitchen appliances, cutlery, sinks),

architectural elements (e.g., handrails, decorative panels), and

medical devices (e.g., surgical instruments) where appearance is

important.

Stainless steel is non-porous and easy to clean, making it highly

suitable for applications where hygiene is critical. Its smooth

surface resists the buildup of bacteria, mold, and other

contaminants. It is extensively used in the food and beverage

industry (e.g., food processing equipment, dairy machinery),

pharmaceutical industry (e.g., clean rooms, laboratory equipment),

and healthcare (e.g., hospital equipment, surgical tools) where

maintaining cleanliness is essential.

Stainless steel can withstand high temperatures without significant

degradation. It maintains its strength and stability even in

high-heat environments, making it suitable for applications

involving thermal processes. It is used in industrial furnaces,

heat exchangers, and automotive exhaust systems, where it can

resist oxidation and scaling at elevated temperatures.

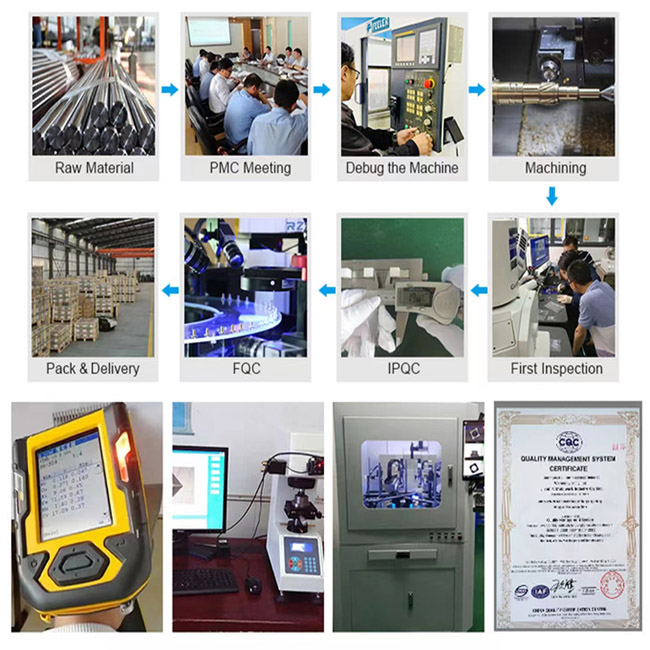

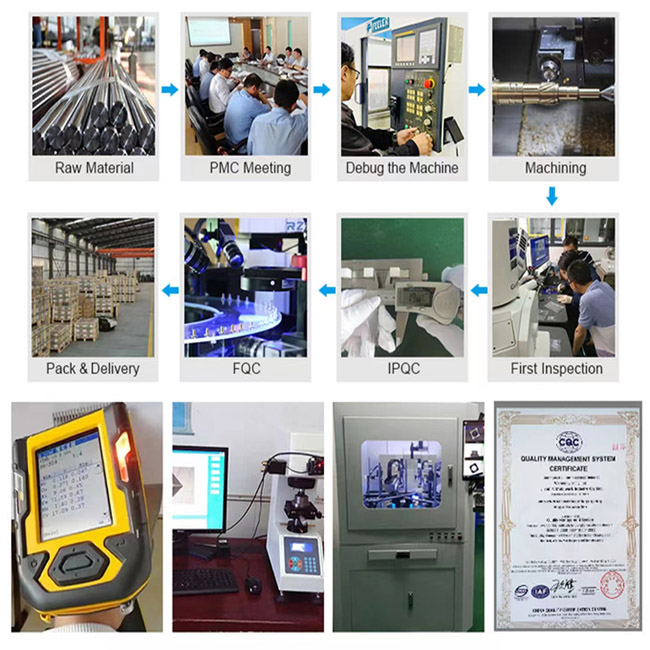

About Us

Package