| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | IC Bonding Machine |

|---|---|

| Brand Name: | Suneast |

| Model Number: | WBD2200 PLUS |

| Certification: | CE、ISO |

| Place of Origin: | Shenzhen, Guangdong Province, China |

| MOQ: | ≥1 pc |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Delivery Time: | 25~50 days |

| Packaging Details: | Plywood crate |

| Name: | IC Bonder |

| Model: | WBD2200 PLUS |

| Machine dimension: | 2480(L)*1470(W)*1700(H)mm |

| Placement accuracy: | ≤±15um@3σ |

| Placement angle accuracy: | ±0.3 °@3σ |

| Die size: | 0.25*0.25mm-10*10mm |

| Core module movement mode: | Linear motor + grating scale |

| Glue feeding mode: | Dispensing + painting glue |

| Loading / Unloading: | Manual / auto |

| Customizable: | Yes |

| Company Info. |

| Suneast Intelligent Equipment Technology (Shenzhen) Co.Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

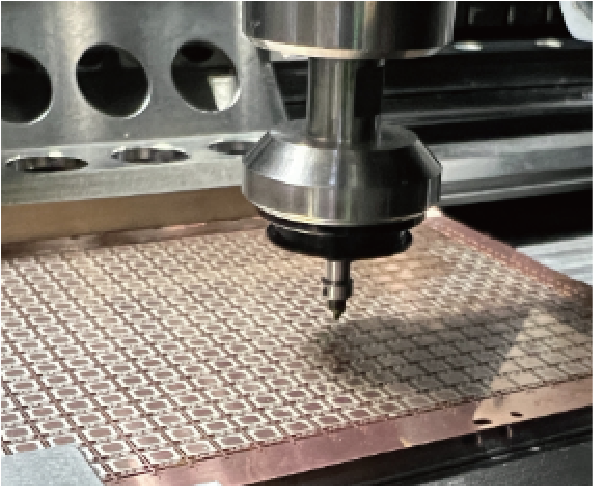

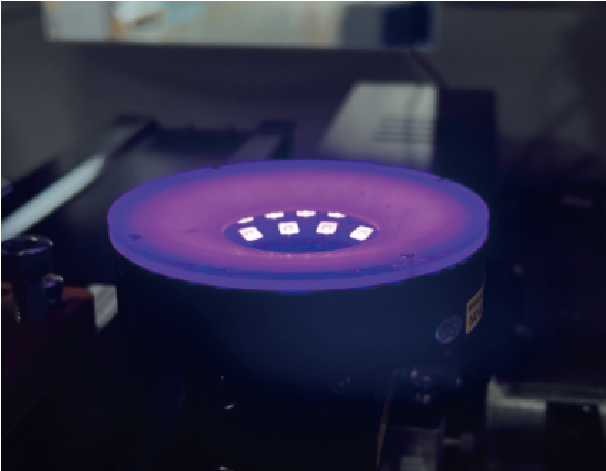

Automatic Nozzle Change High Precision IC Bonding Machine WBD2200 PLUS 8-12 Inch Wafers

General type high-precision IC bonder, which is suitable for mass wafer loading products, SIP packaging, Memory Stack Die (memory stack), CMOS, MEMS and other processes.

Features:

Main application:

It is suitable for mass wafer loading products, and for SIP packaging, Memory Stack Die (memory stack), CMOS, MEMS and other processes. It is mainly used in automotive electronics, medical electronics, optoelectronics, mobile phones and other industries.

Product advantage:

High precision Accuracy :±15μm@3σ Angle: Die size: > 1 x 1 mm ±0.3°@3σ Die size: < 1 x 1 mm ±1°@3σ |  |

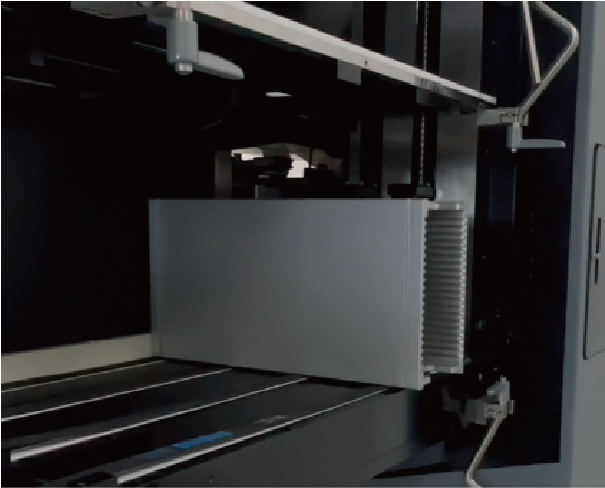

Material box loading Fully automatic feeding and discharging Warehouse processing system, supported by SMEMA online communication agreement,support the SECS/GEM protocol |  |

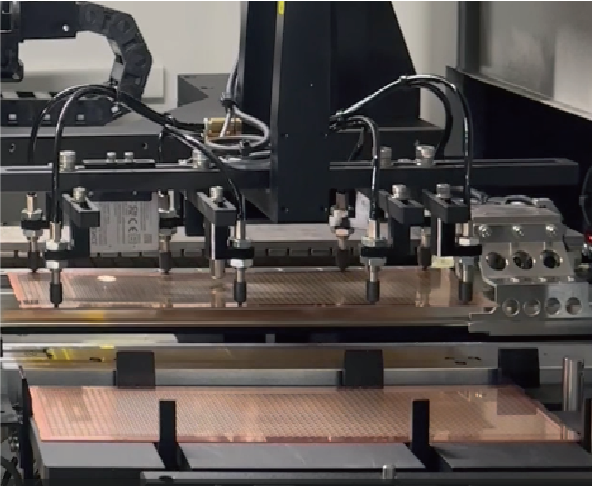

Stacking loading Multiple feeding methods, compatible with stacking feeding function, improving customer selectivity |  |

Nozzle station Equipped with a fully automatic wafer loading and unloading processing system, support to the SECS/GEM protocol |  |

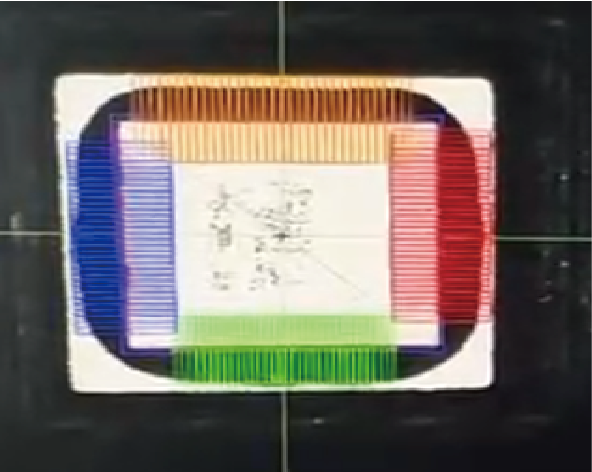

Visual recognition 2448x2048 resolution 256 gray levels Support gray value template, custom shape template The platform can be positioned twice The angle error is ±0.01deg |  |

Real-time compensation It can detect the image after bonding and do automatic real-time compensation to ensure stable mounting accuracy |  |

Product Parameters:

| Item | Specification |

| Placement accuracy | ±15um@3σ |

| Placement angle accuracy | ±0.3°@3σ |

| Force control range | 20~1000g(with different configurations, the maximum support is 7500g) |

| Force control accuracy | 20g-150g:± 2g@3σ 150g-1000g:±5%@3σ |

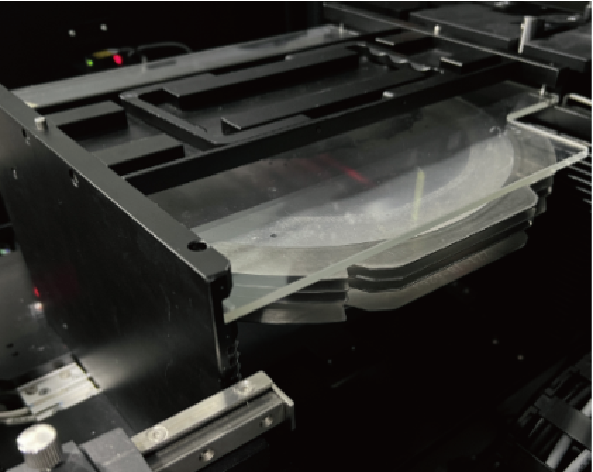

| Silicon wafer processing(mm) | Maximum 12“(300mm) Compatible 8”(150mm) |

| Die size(mm) | 0.25*0.25mm-10*10mm |

| Loading / Unloading | Manual / auto |

| Applicable material box(mm) | L 110-310; W 20-110; H 70-153 |

| Applicable lead frame(mm) | L 100-300; W38-100; H 0.1-0.8 |

| Core module movement mode | Linear motor + grating scale |

| Glue feeding mode | Dispensing + painting glue |

| Bottom photo-taking | Option |

| Machine dimension(mm) | L(2480)*W(1470)*H(1700) |

| Weight | Net weight of equipment:Approx.1800Kg |

Notices:

1.Leakage protection switch: ≥100ma

2.Compressed air requirement: 0.4-0.6Mpa

Inlet pipe specification: Ø10mm

3.Vacuum requirement:<-88kPa

Inlet pipe specification: Ø10mm

Tracheal joint: 2 pieces

4.Power requirements:

①Voltage: AC220V, frequency 50/60HZ;

②Wire requirements: Three core power copper wire, wire diameter≥2.5mm², leakage protection switch 50A, leakage protection switch leakage≥100mA.

5.The ground is required to withstand a pressure of 800kg/m²

|