| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | CNC Cutting Service |

|---|---|

| Brand Name: | HS |

| Model Number: | HS-404 |

| Certification: | ISO9001:2015 |

| Place of Origin: | Guangdong |

| MOQ: | 1,Piece/Pieces |

| Price: | USD,2.85-6.78,Piece/Pieces |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 5000,Piece/Pieces,Month |

| Delivery Time: | 3-7 days for sample order, 10-15 days for bulk order after |

| Packaging Details: | EPE foam inside and Carton outside or EPE foam inside and Wooden outside |

| Product name: | Machining Parts |

| Surface treatment: | Anodizing,polishing,chrome as your request |

| Service: | OEM /ODM |

| Apply to: | Any OEM cnc machining parts |

| Sample: | Need to pay sample fee |

| Tolerance: | 0.01-0.005mm |

| Process: | Cnc Machining+deburrs |

| Feature: | durable and high precision |

| Color: | Customized Color |

| Company Info. |

| Shenzhen Hongsinn Precision Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

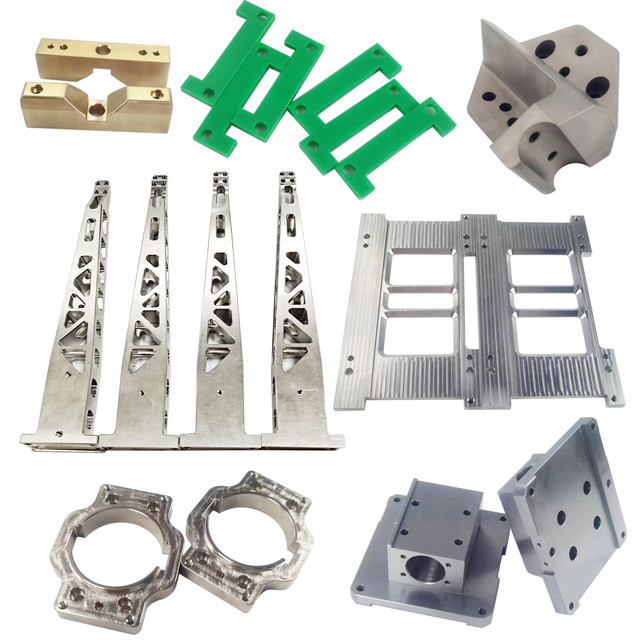

Crafting Uniqueness: Your Vision, Our Precision in Bespoke Machining!

Pom Uhmwpe Nylon Plastic Parts CNC Part China Oem Mcanique Mtal Fabrication

CNC Stainless 316 Part Mechanical Quality Service Spare Services 303 Hardware Fabrication Steel Machining Parts

Processing | CNC turning, CNC milling, CNC machining, Grinding, Die

casting,Friction Welder,Injection Molding | |||

Materials | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. | |||

Stainlesss steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | ||||

Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | ||||

Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper | ||||

Titanium: Grade F1-F5 | ||||

Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK

etc | ||||

Surface Treatment | Anodizing,Brushing,Galvanized,laseren graving,polishing,Powder

coating,knurling,Bead blasted etc | |||

Tolerance | ±0.002 ~ ±0.005mm | |||

Surface Roughness | Min Ra 0.1~3.2 | |||

Quality Assurance | ISO9001, IAFT16949 | |||

The 5-axis CNC machining center is a versatile CNC machine tool that integrates milling, precision milling, precise boring, drilling, and reaming operations.

It finds frequent application in machining high-precision components like fuselage parts and spiral grooves within the aerospace sector, as well as in crafting medical devices, inclined slots, and holes.

Capable of achieving precision levels up to +0.005mm, this system demonstrates remarkable positioning accuracy, guaranteeing consistent and reliable machining quality for parts.

Through the implementation of one-time workpiece clamping, it reduces potential positioning errors associated with multiple setups, relying on the equipment's inherent precision to maintain processing excellence.

This configuration excels particularly in processing components like shafts, gears, and drive shafts following hardening heat treatment, showcasing its proficiency in handling post-treatment machining operations with precision and reliability.

With a focus on reducing processing time, improving accuracy, and facilitating the machining of all five surfaces in a single clamping process, this system is designed to optimize operations efficiently.

By minimizing the necessity for repeated reclamping, it enhances machining precision within a tight range of ±0.005mm.

This setup demonstrates versatility by processing a range of materials such as copper, iron, aluminum alloy, stainless steel, and , showcasing its adaptability across diverse material types.

Efficiently reducing part processing time, this system boosts overall production efficiency. It delivers precise outcomes with machining accuracy ranging between 0.005mm to 0.01mm, coupled with high positioning accuracy.

The system maintains stable and reliable processing quality, ensuring consistency in part production across identical processing conditions, tool applications, and programs. This consistency results in uniform tool paths and the creation of high-quality, dependable parts.

FAQ:

|